(a)

Interpretation:

Estimation of parameters a, b and c from the given equation and data of composition versus excess enthalpy.

Concept introduction:

Excess molar properties of mixtures are the non ideal nature of real mixtures. They are generally the difference between the partial molar property of a component in a real mixture and in an ideal mixture.

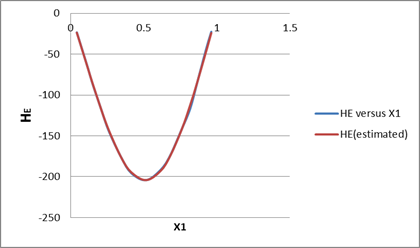

Parameters a, b and c can be determined by fitting the data given in the question.

(a)

Answer to Problem 10.33P

Parameters of the given equations are:

Explanation of Solution

We know that the mole fraction of the second component in a mixture can be written as

Which reduces the given equation of excess volume as:

For calculating parameters using the best fit metod of data to the equation, we must assume initial parameters as:

a = -500 ; b = -100 and c = 0.1

Now we will estimate values of HE using given equation and assumed parameters and find the error using formula given below:

After finding error, we have to minimize the error to best fit the given and estimated data by finding parameter in excel solver as described below:

| x1 | HE(given) | HE(estimated) | Normalized error |

| 0.0426 | -23.3 | -23.2149 | 0.000255 |

| 0.0817 | -45.7 | -45.633 | 0.00011 |

| 0.1177 | -66.5 | -66.6008 | 6.04E-05 |

| 0.151 | -86.6 | -85.833 | 4.78E-05 |

| 0.2107 | -118.2 | -118.781 | 1.08E-06 |

| 0.2624 | -144.6 | -144.559 | 5.81E-05 |

| 0.3472 | -176.6 | -178.669 | 9.94E-07 |

| 0.4158 | -195.7 | -196.933 | 2.64E-05 |

| 0.5163 | -204.2 | -206.209 | 1.4E-08 |

| 0.6156 | -191.7 | -193.963 | 4.17E-05 |

| 0.681 | -174.1 | -174.738 | 1.05E-05 |

| 0.7621 | -141 | -140.126 | 3.45E-06 |

| 0.8181 | -116.8 | -110.579 | 0.001453 |

| 0.865 | -85.6 | -83.2654 | 1.4E-05 |

| 0.9276 | -43.5 | -44.7103 | 0.004488 |

| 0.9624 | -22.6 | -23.0104 | 0.004457 |

| Sum of error | 0.011027 | ||

| Estimated | Assumed | ||

| a | -530 | -500 | |

| b | -1129 | -100 | |

| c | 1050 | 0.1 |

By the linear fitting of the given data in the given equation, we will get parameters as:

(b)

Interpretation:

Estimation the minimum value of excess enthalpy and composition at which it becomes minimum.

Concept introduction:

Excess molar properties of mixtures are the non ideal nature of real mixtures. They are generally the difference between the partial molar property of a component in a real mixture and in an ideal mixture.

(b)

Answer to Problem 10.33P

Minimum value of excess enthalpy = -204.4 J/mol at composition 0.512.

Explanation of Solution

We know that the mole fraction of the second component in a mixture can be written as

Which reduces the given equation of excess enthalpy as:

Put the determined parameter values from part (a) to the equation (1), we get:

Now differentiate above equation with respect to x1 and equate it to zero gives:

Now we will find the value of x1 which satisfies the above equation:

Let x1 = 0.5

Near to zero, so composition will be approximately 0.5 or 0.513.

So, at x1 = 0.513 excess enthalpy will be a minumum and the minimum value of excess enthalpy can be calculated as given below:

(c)

Interpretation:

Derive expression for

Concept introduction:

Excess molar properties of mixtures are the non ideal nature of real mixtures. They are generally the difference between the partial molar property of a component in a real mixture and in an ideal mixture.

Partial molar properties can be derived from equations:

(c)

Answer to Problem 10.33P

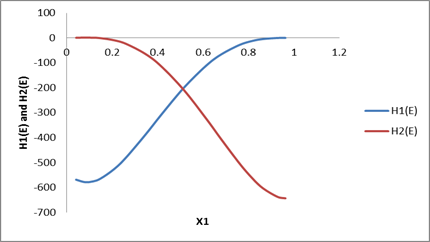

Expression of partial molar properties is:

The graph plotted between partial molar properties and composition.

Explanation of Solution

We know that the mole fraction of the second component in a mixture can be written as

Which reduces the given equation of excess enthalpy as:

Put the determined parameter values from part (a) to the equation (1), we get:

Now differentiate the above equation with respect to x1 and get:

The expression for partial molar enthalpy can be written as follows:

Plot of partial molar properties derived above with x1 can be drawn as follows:

We know that,

So, the partial molar equations become:

| x1 | HE | H1(E ) | H2(E ) |

| 0.0426 | -23.3 | -568.736 | 0.760504 |

| 0.0817 | -45.7 | -584.771 | 1.762019 |

| 0.1177 | -66.5 | -585.497 | 1.796789 |

| 0.151 | -86.6 | -576.017 | 0.291058 |

| 0.2107 | -118.2 | -539.462 | -7.96384 |

| 0.2624 | -144.6 | -492.7 | -22.5599 |

| 0.3472 | -176.6 | -398.129 | -64.4174 |

| 0.4158 | -195.7 | -315.445 | -115.569 |

| 0.5163 | -204.2 | -200.304 | -216.279 |

| 0.6156 | -191.7 | -107.319 | -337.296 |

| 0.681 | -174.1 | -61.7537 | -421.072 |

| 0.7621 | -141 | -23.8448 | -518.49 |

| 0.8181 | -116.8 | -8.90102 | -574.265 |

| 0.865 | -85.6 | -2.30111 | -608.877 |

| 0.9276 | -43.5 | 0.450114 | -630.781 |

| 0.9624 | -22.6 | 0.303215 | -627.571 |

Plot drawn according to data calculated in the above table as:

Want to see more full solutions like this?

Chapter 10 Solutions

Introduction to Chemical Engineering Thermodynamics

- For spherical sand particles with Dp = 0.03 and ρparticles = 150 lbm / ft3 estimate the minimum fluidizing velocity for air and for water. Assume ε = 0.3. In the case of the water we must rederive Eq. 11.42, taking into account the buoyant force on the particles. Below are the provide answers. Please show all work to get to the correct answers.arrow_forwardPlease show all workarrow_forward2. A moving bed adsorption column needs to be designed to separate hydrophobic proteins from a fermentation broth. The following adsorption equilibrium data was observed in preliminary isotherm studies. The resin used was activated carbon with a porosity of 0.2. The overall mass transfer coefficient was determined to be 10 h¹, and the ratio of volumetric flow rate of broth to resin is 10. Determine the diameter of the column if the column height is limited to 2.5 m (indoor operation) with a flow rate of 20 m³/h, influent concentration of 7 g/L, and effluent concentration of 0.1 g/L. qi (mg/kg) Ci (g/L) 0.1 4.7 7.5 0.25 10.6 0.5 15.0 1.0 23.7 2.5 33.5 5.0 41.1 7.5arrow_forward

- 3. You are given a mixture of four proteins, whose properties are listed in the table below. Propose a process to purify each protein so that you end up with four solutions of pure protein. What resin would you use to bind the protein(s)? What changes to the buffer would you make to desorb the protein(s)? Contains an N-terminal His6-tag. Two 50 kDa subunits contain a non-heme Fe2+ in the active site. Protein Size (kDa) pl Specific Properties A 100 6.0 B 40 7.7 C 240 8.3 Ꭰ 225 5.5 Contains FAD redox center and an NADH binding domain. Composed of six 40-kDa subunits, each of which contains a [2Fe-2S] cluster. Composed of three subunits: 100 kDa structural subunit, 75 kDa subunit with a molybdopterin center, and 50 kDa subunit with FAD and an NADH binding domain.arrow_forwardb) Explain the key features of the Langmuir adsorption model - Drawing a diagram with empty and occupied sites. Show how new molecules would adsorb. drawing the diagram, showing free and empty sites, and their number (to use for next section) - Define the capacity and binding affinity parameters in terms of things shown on the diagram Defining the capacity and binding affinity parameters in terms of bound, free sites, and free molecules - Plot what would be a typical breakthrough curve and give an explanation approximately when breakthrough would occur plotting a typical sigmoidal breakthrough curve and saying it would certainly occur by the time capacity is used, but also could be much earlier if the affinity is lowarrow_forwardWater at 20°C flows at a steady average velocity of 5.25 m/s through a smooth pipe of diameter 5.08 cm. The flow is fully developed through the entire section of pipe. The total pipe length is 10.56 m, and there are two 90' elbows. Determine the friction coefficient and the head loss due to friction per meter length of the pipe. Control volume Prepared by Engr. Kirsten Gaarrow_forward

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY

Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The