Masoline Aldernite Materials/Labor Available Molding Materials 30 pounds per door 45 pounds per door 540,000 pounds $3 per pound Finishing Time 3 hours per door 4 hours per door 102,000 hours $15 per hour Selling Price $235 per door $305 per door Cost of materials and labor The following requirements refer only to the preceding data. There is no connection between the requirements. 1. If there were enough demand for either door, which door would DF produce? How many of these doors would it make and sell? 2. If DF sells three Masoline for each Aldernite, how many doors of each type would it produce and sell? What would be the total contribution margin? 3. If DF sells three Masoline for each Aldernite, how much would production and contribution margin increase if the molding department could buy 9,000 more pounds of materials for $3 per pound? 4. If DF sells three Masoline for each Aldernite, how much would production and contribution margin increase if the assembly department could get 780 more labor hours at $15 per hour? Required

Theory of constraints, contribution margin, sensitivity analysis. Damon Furniture (DF) produces berglass doors in two processes: molding and nishing. DF is currently producing two models: Masoline and Aldernite. Production in the molding department is limited by the amount of materials available. Production in the nishing department is limited by the amount of trained labor available. The only variable costs are materials in the molding department and labor in the nishing department. Following are the requirements and limitations by model and department:

Hey, since there are multiple requirements posted, we will answer first three requirements. If you want any specific requirement to be answered then please submit the question by specifying the requirement that need to be solved in your message.

1.

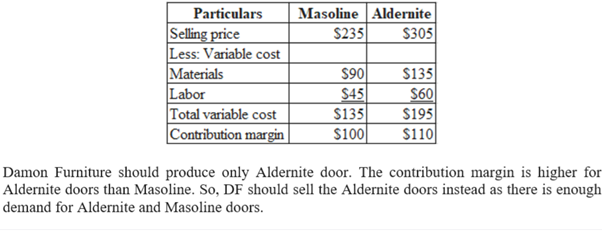

Compute contribution margins for the doors as shown below:

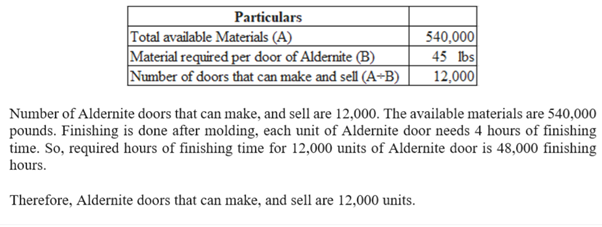

Compute number of doors that can make and sell as shown below:

Step by step

Solved in 4 steps with 5 images