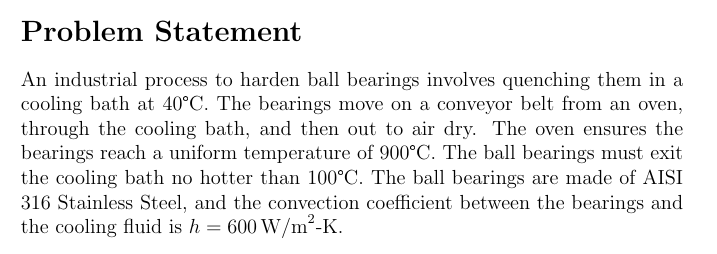

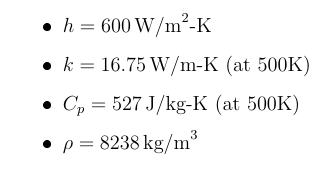

An industrial process to harden ball bearings involves quenching them in a cooling bath at 40°C. The bearings move on a conveyor belt from an oven, through the cooling bath, and then out to air dry. The oven is long enough that the bearings reach a uniform temperature of 900°C before exiting the oven. The ball bearings must exit the cooling bath no hotter than 100°C. The ball bearings are made of AISI 316 Stainless Steel and the convection coefficient between the bearings and the cooling fluid can be considered constant at ℎ = 600 W m2-K⁄ . You can find thermophysical properties of different materials in Appendix A of the Bergman textbook. a) What is the largest diameter ball bearing that can be treated as thermally lumped for this cooling process? Take ? at a reasonable average temperature for this process. You do not need to interpolate if the average temperature is within ~30 K of a given table value. b) The cooling bath is 5 m long. Using the diameter you found in part (a), estimate the speed of the conveyor belt. c) This quenching system is intended to process 5000 ball bearings per hour. Using the diameter you found in part (a), determine the rate at which energy must be removed from the cooling bath to maintain it at 40°C.

An industrial process to harden ball bearings involves quenching them in a cooling bath at

40°C. The bearings move on a conveyor belt from an oven, through the cooling bath, and

then out to air dry. The oven is long enough that the bearings reach a uniform temperature

of 900°C before exiting the oven. The ball bearings must exit the cooling bath no hotter

than 100°C. The ball bearings are made of AISI 316 Stainless Steel and the convection

coefficient between the bearings and the cooling fluid can be considered constant at ℎ =

600 W m2-K⁄ . You can find thermophysical properties of different materials in Appendix A

of the Bergman textbook.

a) What is the largest diameter ball bearing that can be treated as thermally lumped

for this cooling process? Take ? at a reasonable average temperature for this process.

You do not need to interpolate if the average temperature is within ~30 K of a given

table value.

b) The cooling bath is 5 m long. Using the diameter you found in part (a), estimate the

speed of the conveyor belt.

c) This quenching system is intended to process 5000 ball bearings per hour. Using

the diameter you found in part (a), determine the rate at which energy must be

removed from the cooling bath to maintain it at 40°C.

Trending now

This is a popular solution!

Step by step

Solved in 5 steps with 7 images