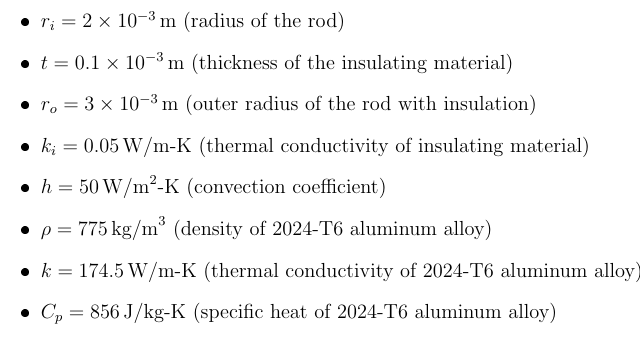

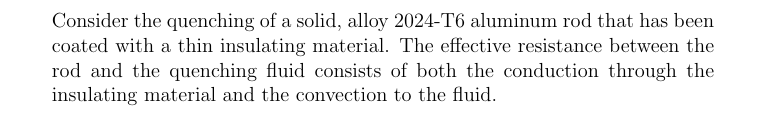

In general, it is helpful to think of a thermally lumped object as being "tied down" to some reference temperature through a general thermal resistance. In the simplest case this is a single thermal resistance (e.g., just convection), but there are cases for which this thermal resistance is composed of more than one heat transfer mechanism. Consider the quenching of a solid, alloy 2024-T6 aluminum rod that has been coated with a thin insulating material. If the insulating material is thin enough that its thermal energy storage capacity can be ignored, the effective resistance between the rod and the quenching fluid consists of both the conduction through the insulating material and the convection to the fluid. a) The simplest version of the Biot number is Bi= he. When there are multiple external resistances between the lumped object at the surroundings the Biot number generalizes to Bi = UL, where U is the overall heat transfer coefficient between the lumped object and the surroundings. The aluminum alloy rod described above is perfectly insulated on either end (i.e., the top and bottom) and has a 2 mm radius. The rod is long enough that the heat transfer in the rod can be considered one dimensional in the radial direction. The insulating coating on the rod has thermal conductivity k = 0.05 W/m. K and is t = 0.1 mm thick. The convection coefficient between the coating and the quenching fluid is h = 50 W/m².K. i. Recall that we must explicitly identify the reference surface area when defining the overall heat transfer coefficient for a radial system. To make a conservative estimate of the validity of lumped capacitance-in the sense of feeling most confident in making the lumped approximation-we would want to use the largest value of U. Which reference surface area will produce the largest U? ii. Verify that the lumped capacitance model is valid for this quenching process. For simplicity, estimate the properties of the alloy as being constant at 300 K. b) If the rod is to be cooled to the surrounding fluid temperature, estimate the time required for this quenching process.

In general, it is helpful to think of a thermally lumped object as being “tied down” to some

reference temperature through a general thermal resistance. In the simplest case this is a

single thermal resistance (e.g., just convection), but there are cases for which this thermal

resistance is composed of more than one heat transfer

of a solid, alloy 2024-T6 aluminum rod that has been coated with a thin insulating material.

If the insulating material is thin enough that its thermal energy storage capacity can be

ignored, the effective resistance between the rod and the quenching fluid consists of both

the conduction through the insulating material and the convection to the fluid.

a) The simplest version of the Biot number is Bi = ℎ??

? . When there are multiple

external resistances between the lumped object at the surroundings the Biot number

generalizes to Bi = ???

? , where ? is the overall heat transfer coefficient between the

lumped object and the surroundings.

The aluminum alloy rod described above is perfectly insulated on either end

(i.e., the top and bottom) and has a 2 mm radius. The rod is long enough that the

heat transfer in the rod can be considered one dimensional in the radial direction.

The insulating coating on the rod has thermal conductivity ?? = 0.05 W m ⋅ K⁄ and

is ? = 0.1 mm thick. The convection coefficient between the coating and the

quenching fluid is ℎ = 50 W m2 ⋅ K⁄ .

i. Recall that we must explicitly identify the reference surface area when

defining the overall heat transfer coefficient for a radial system. To

make a conservative estimate of the validity of lumped capacitance—in

the sense of feeling most confident in making the lumped

approximation—we would want to use the largest value of ?. Which

reference surface area will produce the largest ??

ii. Verify that the lumped capacitance model is valid for this quenching

process. For simplicity, estimate the properties of the alloy as being

constant at 300 K.

b) If the rod is to be cooled to the surrounding fluid temperature, estimate the time

required for this quenching process

Step by step

Solved in 4 steps with 7 images