Concept explainers

Question

☆New England Foundry

For more than 75 years, New England Foundry, Inc. (NEFI), has manufactured wood stoves for home use. In recent years, with increasing energy prices, president George Mathison has seen sales triple. This dramatic increase has made it difficult for George to maintain quality in all his wood stoves and related products.

Unlike other companies manufacturing wood stoves, NEFI is in the business of making only stoves and stove-related products. Its major products are the Warmglo I, the Warmglo II, the Warmglo III, and the Warmglo IV. The Warmglo I is the smallest wood stove, with a heat output of 30,000 BTUs, and the Warmglo IV is the largest, with a heat output of 60,000 BTUs.

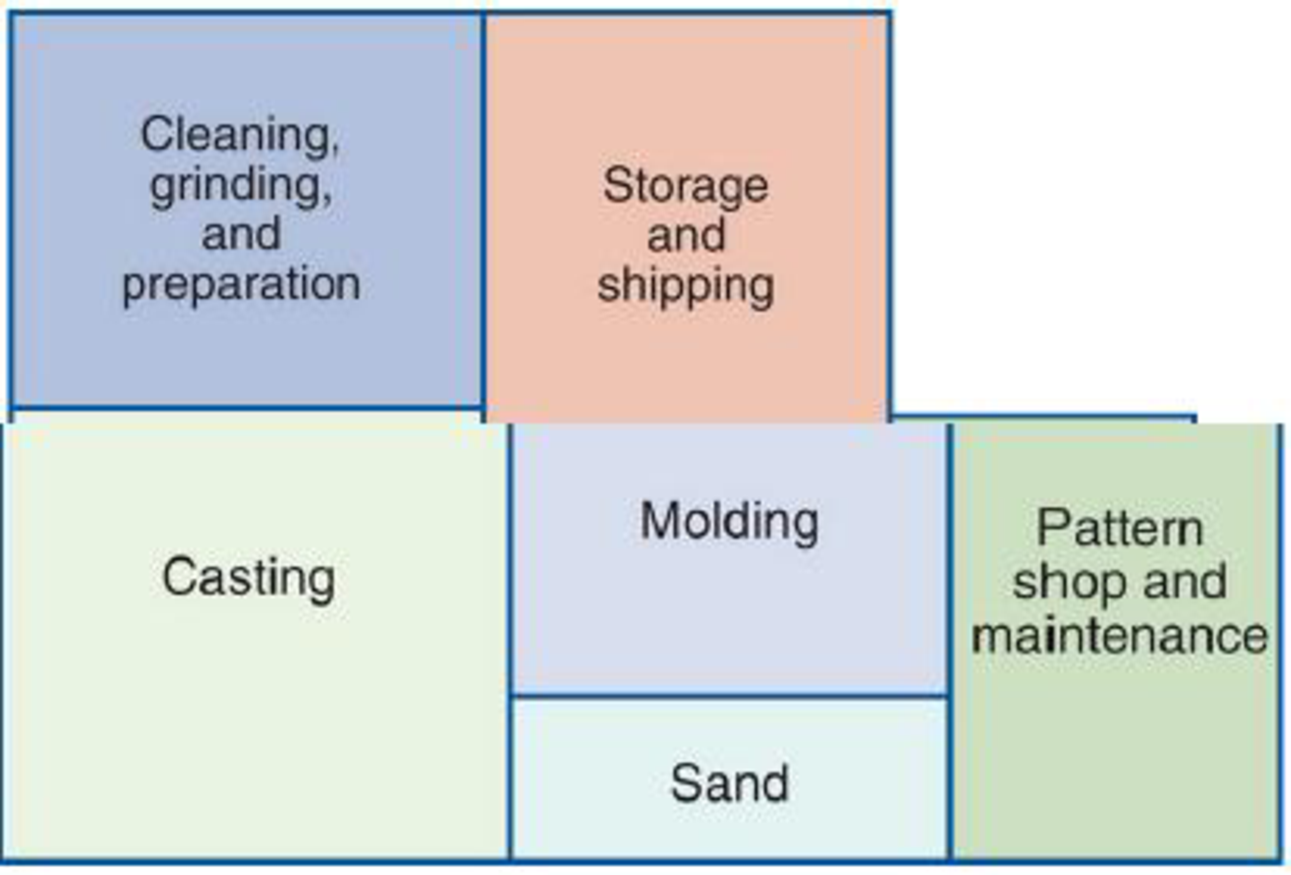

The Warmglo III outsold all other models by a wide margin. Its heat output and available accessories were ideal for the typical home. The Warmglo III also had a number of other outstanding features that made it one of the most attractive and heat-efficient stoves on the market. These features, along with the accessories, resulted in expanding sales and prompted George to build a new factory to manufacture the Warmglo III model. An overview diagram of the factory is shown in Figure D.6.

Figure D.6 Overview of Factory

The new foundry used the latest equipment, including a new Disamatic that helped in manufacturing stove parts. Regardless of new equipment or procedures, casting operations have remained basically unchanged for hundreds of years. To begin with, a wooden pattern is made for every cast-iron piece in the stove. The wooden pattern is an exact duplicate of the cast-iron piece that is to be manufactured. All NEFI patterns are made by Precision Patterns, Inc. and are stored in the pattern shop and maintenance room. Next, a specially formulated sand is molded around the wooden pattern. There can be two or more sand molds for each pattern. The sand is mixed and the molds are made in the molding room. When the wooden pattern is removed, the resulting sand molds form a negative image of the desired casting.

Next, molds are transported to the casting room, where molten iron is poured into them and allowed to cool. When the iron has solidified, molds are moved into the cleaning, grinding, and preparation room, where they are dumped into large vibrators that shake most of the sand from the casting. The rough castings are then subjected to both sandblasting to remove the rest of the sand and grinding to finish some of their surfaces. Castings are then painted with a special heat-resistant paint, assembled into workable stoves, and inspected for manufacturing defects that may have gone undetected. Finally, finished stoves are moved to storage and shipping, where they are packaged and transported to the appropriate locations.

At present, the pattern shop and the maintenance department are located in the same room. One large counter is used by both maintenance personnel, who store tools and parts (which are mainly used by the casting department), and sand molders, who need various patterns for the molding operation. Pete Nawler and Bob Dillman, who work behind the counter, can service a total of 10 people per hour (about 5 per hour each). On average, 4 people from casting and 3 from molding arrive at the counter each hour. People from molding and casting departments arrive randomly, and to be served, 1hey form a single line.

Pete and Bob have always had a policy of first come, first served. Because of the location of the pattern shop and maintenance department, it takes an average of 3 minutes for an individual from the casting department to walk to the pattern and maintenance room, and it takes about 1 minute for an individual to walk from the molding department to the pattern and maintenance room.

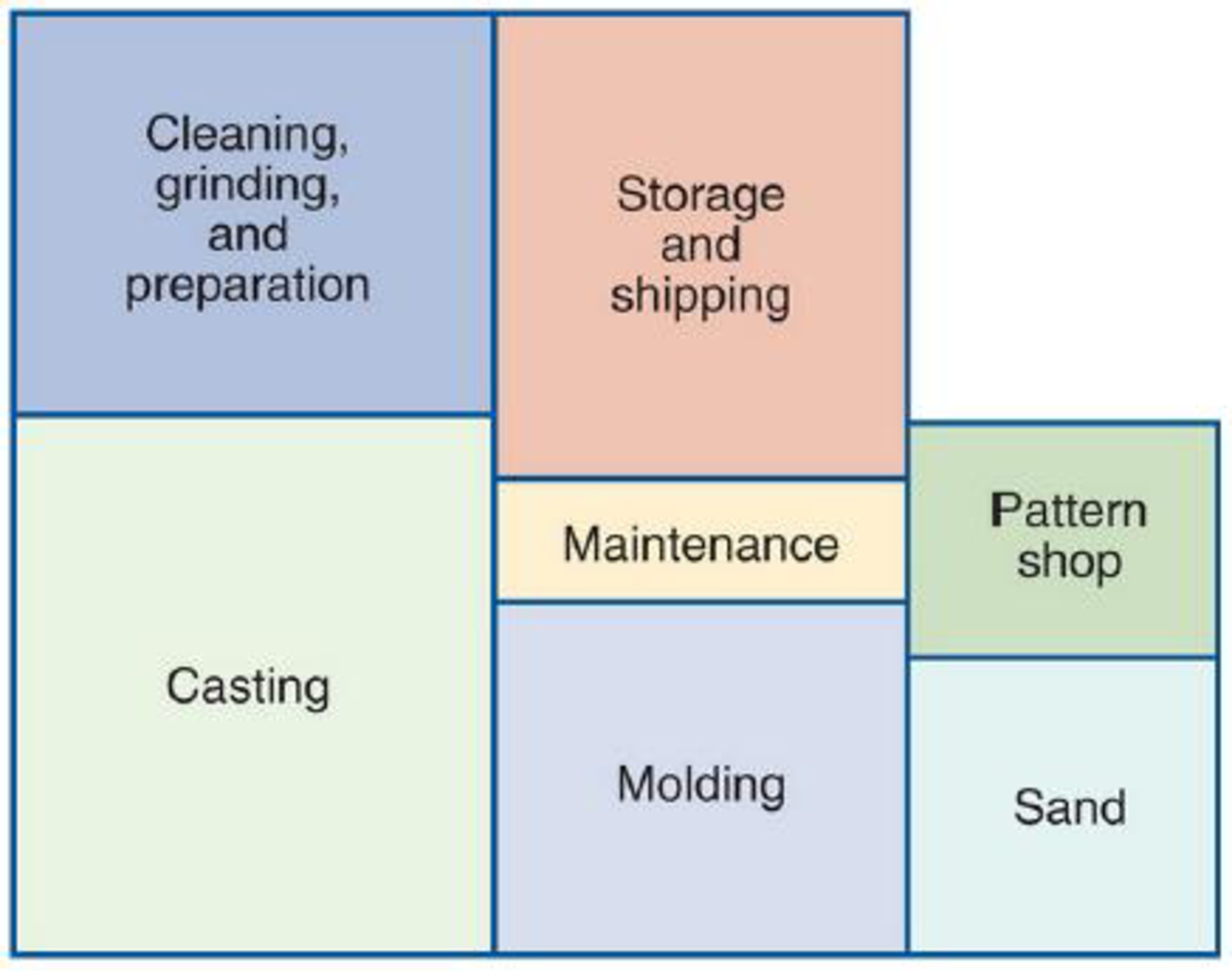

After observing the operation of the pattern shop and maintenance room for several weeks, George decided to make some changes to the factory layout. An overview of these changes appears in Figure D.7.

Figure D.7 Overview of Factory after Changes

Separating the maintenance shop from the pattern shop would have a number of advantages. It would take people from the casting department only 1 minute instead of 3 to get to the new maintenance room. The time from molding to the pattern shop would be unchanged. Using motion and time studies, George was also able to determine that improving the layout of the maintenance room would allow Bob to serve 6 people from the casting department per hour; improving the layout of the pattern department would allow Pete to serve 7 people from the molding shop per hour.

1. How much time would the new layout save?

Want to see the full answer?

Check out a sample textbook solution

Chapter D Solutions

Operations Management

- 4. Based on the data provided in Table 2.5, what is the flow rate of callers from 8:00 a.m. to 8:20 a.m.? TABLE 2.5 Time Stamps of the Eight Callers Who Called from 8:00 a.m. to 8:20 a.m. to the Reservation Desk of a Ferry Service Caller Time In Time Out 1 8:01 8:05 2 3 4 5 6 8:02 8:07 8:06 8:08 8:09 8:12 8:10 8:15 8:12 8:20 7 8:16 8:19 8 8:17 8:19 5. Based on the data provided in Table 2.5, what is the flow time of callers from 8:00 a.m. to 8:20 a.m.? 6. Based on the data provided in Table 2.6, what is the flow rate of customers from 9:00 a.m. to 10:00 a.m.? TABLE 2.6 Time Stamps of 10 Customers Who Visited a Local Bank Branch from 9:00 a.m. to 10:00 a.m. Customer 1 2 3 4 5 6 7 8 9 10 Time In Time Out 9:01 9:07 9:06 9:21 9:08 9:20 9:14 9:19 9:20 9:28 9:26 9:33 9:31 9:39 9:40 9:46 9:44 9:59 9:53 9:57 7. Based on the data provided in Table 2.6, what is the flow time of customers from 9:00 a.m. to 10:00 a.m.?arrow_forwardHow is Little’s Law currently used in today’s supply chains? Provide an example of where it is used.arrow_forwardHow would you Briefly state your views on music for a Christian school interview?arrow_forward

- 3) Rane Brake Linings manufactures brake pads in a process focused facility; the fixed costs are nine thousand dollars per year, the variable cost is fifty dollars per brake pad, each brake pad sells for two hundred dollars. a) Calculate the breakeven point (in units) for this operation. b) Calculate the breakeven point (in $) for this operation. c) Calculate the profit/loss on a demand of two hundred brake pads per year. Note: You could work out the problem by hand or use excel; in chapter 5, section 5.11 of the Stevenson text, evaluating alternatives (cost volume analysis) is covered with examples; chapter 5 Stevenson lecture power point slides 34 to 44 (chapter 5 lecture: 29.49 mins to 38.87 mins) cover cost volume analysis with examples.arrow_forward1. For the purpose of process analysis, which of the following measures would beconsidered an appropriate flow unit for analyzing the operation of a coffee shop?Instructions: You may select more than one answer. a. Square footage of the store b. Number of employees working each week c. Number of hours the store is open each week d. Number of customers served each weekarrow_forwardLO2-1 1. From the perspective of process analysis, which of the following could be appropriate flow units for a hardware store? a. Number of workers b. Number of cash registers c. Number of customers d. Number of suppliers page 37 2. Over the course of a month, which of the following is most likely to describe an appropriate flow unit for a process analysis of a hospital? a. The number of physicians b. The number of beds c. The square footage of the building d. The number of patients LO2-2 3. At a cruise ship terminal, each day on average 1000 passengers embark on ships. On average, passengers spend 5 days on their cruise before returning to this terminal. If the flow unit is a passenger, then what are the flow rate and flow time of this process? 4. It is election day and 1800 voters vote in their precinct’s library during the 10 hours the polls are open. On average, there are 15 voters in the library and they spend on average 5 minutes in the library to complete their voting. What is…arrow_forward

- What do you feel is the most effective way to communicate with families? Describe how you have used this/these technique(s).arrow_forwardPP.52 A manufacturer of solid state drives (SSDs) has projected the next six months of demand to be as shown the table below: Supply/Demand Info Beginning Jan Feb Mar Apr May Jun Forecast (demand) 53,800 53,400 51,000 63,800 49,200 59,000 Regular production Overtime production Subcontract production Ending inventory 4,000 Hired employees Fired employees Total employees 190 Cost variables are as follows: Cost Variables Labor cost/hour $16 Overtime cost/unit $39 Subcontracting cost/unit $35 Holding cost/unit/month $14 Hiring cost/employee $3,100 Firing cost/employee $5,500 Here is some additional relevant (capacity) information: Capacity Information Total labor hours/SSD 4 Regular production units/employee/month 200…arrow_forwardDiscuss how a human resource professional can better gain the confidence of senior management and, thereby, become a key participant/player in the organization’s future.arrow_forward

- PP.63 Jupiter, a large candy company, is having great success with its "Swan" family of candy bars. Due to a number of factors they like to plan their production at least six months into the future. The table below contains their demand projections (in tons) for April through September: Supply/Demand Info Beginning Apr May Jun Jul Aug Sep Predicted Sales 45,500 45,100 51,900 52,800 47,900 47,200 Regular production Overtime production Subcontract production Ending inventory 14,400 Hired employees Fired employees Total employees 423 Cost variables are as follows: Cost Variables Labor cost/hour $13 Overtime cost/ton $30 Subcontracting cost/ton $28 Holding cost/ton/month $14 Hiring cost/employee $3,700 Firing cost/employee $5,800 Here is some additional…arrow_forwardWhat are the responsibilities and duties of a consultant for a local company who is considering expanding its operations to international markets? How can a local Agriculture and Food Processing company successfully enter international markets?arrow_forwardWhat is an example of how someone would explain how their past personal and professional experience makes you a quality candidate for a teaching position at an Elementary School as a K-6 Teacher?arrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,