EBK MANUFACTURING ENGINEERING & TECHNOL

7th Edition

ISBN: 8220100793431

Author: KALPAKJIAN

Publisher: PEARSON

expand_more

expand_more

format_list_bulleted

Concept explainers

Textbook Question

Chapter 9, Problem 65SDP

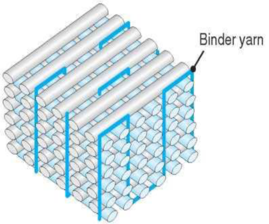

Figure P9.65 shows a section of a three-dimensional weave that uses a binder yarn to tie layers of fibers together. Conduct a literature search, and determine the advantages and limitations of using three-dimensional weaves as reinforcements in composite materials.

FIGURE P9.65

Expert Solution & Answer

Want to see the full answer?

Check out a sample textbook solution

Students have asked these similar questions

Please can you help me with the attached question?

Please can you help me with the attached question?

Please can you help me with the attached question?

Chapter 9 Solutions

EBK MANUFACTURING ENGINEERING & TECHNOL

Ch. 9 - Distinguish between composites and metal alloys.Ch. 9 - Describe the functions of the matrix and the...Ch. 9 - Name the reinforcing fibers generally used to make...Ch. 9 - What is the range in length and diameter of...Ch. 9 - List the important factors that determine the...Ch. 9 - Comment on the advantages and limitations of...Ch. 9 - What are the most commonly used matrix materials?...Ch. 9 - Describe the advantages of hybrid composites over...Ch. 9 - What material properties are improved by the...Ch. 9 - Describe the purpose of the matrix material.

Ch. 9 - What are the most common types of glass fibers?Ch. 9 - Explain the difference between a carbon fiber and...Ch. 9 - How can a graphite fiber be made electrically and...Ch. 9 - What is a whisker? What is the difference between...Ch. 9 - Describe the composition of boron fibers. Why are...Ch. 9 - Give a succinct definition of fiber, yarn, and...Ch. 9 - How do you think the use of straw mixed with clay...Ch. 9 - What products have you personally seen that are...Ch. 9 - Describe applications that are not well suited for...Ch. 9 - Is there a difference between a composite material...Ch. 9 - Identify metals and alloys that have strengths...Ch. 9 - What limitations or disadvantages do composite...Ch. 9 - Give examples of composite materials other than...Ch. 9 - Explain why the behavior of the materials depicted...Ch. 9 - Explain why fibers are so capable of supporting a...Ch. 9 - Do metal-matrix composites have any advantages...Ch. 9 - Give reasons for the development of ceramic-matrix...Ch. 9 - Explain how you would go about determining the...Ch. 9 - How would you go about trying to determine the...Ch. 9 - Glass fibers are said to be much stronger than...Ch. 9 - Describe situations in which a glass could be used...Ch. 9 - When the American Plains states were settled, no...Ch. 9 - By incorporating small amounts of a blowing agent,...Ch. 9 - Referring to Fig. 9.2c, would there be an...Ch. 9 - Calculate the average increase in the properties...Ch. 9 - In Example 9.1, what would be the percentage of...Ch. 9 - Calculate the percent increase in the mechanical...Ch. 9 - Calculate the stress in the fibers and in the...Ch. 9 - Repeat the calculations in Example 9.1 if (a)...Ch. 9 - Refer to the properties listed in Table 7.1. If...Ch. 9 - Plot the elastic modulus and strength of an...Ch. 9 - For the data in Example 9.1, what should be the...Ch. 9 - It is desired to obtain a composite material with...Ch. 9 - A rectangular cantilever beam, 100 mm high, 20 mm...Ch. 9 - What applications for composite materials can you...Ch. 9 - Using the information given in this chapter,...Ch. 9 - Would a composite material with a strong and stiff...Ch. 9 - Make a list of products for which the use of...Ch. 9 - Inspect Fig. 9.1 and explain what other components...Ch. 9 - Name applications in which both specific strength...Ch. 9 - What applications for composite materials can you...Ch. 9 - As with other materials, the mechanical properties...Ch. 9 - Developments are taking place in techniques for...Ch. 9 - As described in this chapter, reinforced plastics...Ch. 9 - Comment on your observations on the design of the...Ch. 9 - Make a survey of various sports equipment and...Ch. 9 - Several material combinations and structures were...Ch. 9 - It is possible to make fibers or whiskers with a...Ch. 9 - Describe how you can produce some simple composite...Ch. 9 - Gel spinning is a specialized process used in...Ch. 9 - Figure P9.65 shows a section of a...

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Please can you help me with the attached question?arrow_forwardPlease can you help me with the attached question?arrow_forward4. The rod ABCD is made of an aluminum for which E = 70 GPa. For the loading shown, determine the deflection of (a) point B, (b) point D. 1.75 m Area = 800 mm² 100 kN B 1.25 m с Area = 500 mm² 75 kN 1.5 m D 50 kNarrow_forward

- Research and select different values for the R ratio from various engine models, then analyze how these changes affect instantaneous velocity and acceleration, presenting your findings visually using graphs.arrow_forwardQu. 7 The v -t graph of a car while travelling along a road is shown. Draw the s -t and a -t graphs for the motion. I need to draw a graph and I need to show all work step by step please do not get short cut from dtnaarrow_forwardAn unpressurized cylindrical tank with a 100-foot diameter holds a 40-foot column of water. What is total force acting against the bottom of the tank?arrow_forward

- 7. In the following problems check to see if the set S is a vector subspace of the corresponding R. If it is not, explain why not. If it is, then find a basis and the dimension. (a) S = (b) S = {[],+,"} X1 x12x2 = x3 CR³ {[1], 4+4 = 1} CR³ X2arrow_forwardAAA Show laplace transform on 1; (+) to L (y(+)) : SY(s) = x (0) Y(s) = £ [lx (+)] = 5 x(+) · est de 2 -St L [ y (^) ] = So KG) et de D 2 D D AA Y(A) → Y(s) Ŷ (+) → s Y(s) -yarrow_forward1) In each of the following scenarios, based on the plane of impact (shown with an (n, t)) and the motion of mass 1, draw the direction of motion of mass 2 after the impact. Note that in all scenarios, mass 2 is initially at rest. What can you say about the nature of the motion of mass 2 regardless of the scenario? m1 15 <+ m2 2) y "L χ m1 m2 m1 בז m2 Farrow_forward

- 8. In the following check to see if the set S is a vector subspace of the corresponding Rn. If it is not, explain why not. If it is, then find a basis and the dimension. X1 (a) S = X2 {[2], n ≤ n } c X1 X2 CR² X1 (b) S X2 = X3 X4 x1 + x2 x3 = 0arrow_forward2) Suppose that two unequal masses m₁ and m₂ are moving with initial velocities V₁ and V₂, respectively. The masses hit each other and have a coefficient of restitution e. After the impact, mass 1 and 2 head to their respective gaps at angles a and ẞ, respectively. Derive expressions for each of the angles in terms of the initial velocities and the coefficient of restitution. m1 m2 8 m1 ↑ บา m2 ñ Вarrow_forwardThe fallowing question is from a reeds book on applied heat i am studying. Although the answer is provided, im struggling to understand the whole answer and the formulas and the steps theyre using. Also where some ov the values such as Hg and Hf come from in part i for example. Please explain step per step in detail thanks In an NH, refrigerator, the ammonia leaves the evaporatorand enters the cornpressor as dry saturated vapour at 2.68 bar,it leaves the compressor and enters the condenser at 8.57 bar with50" of superheat. it is condensed at constant pressure and leavesthe condenser as saturated liquid. If the rate of flow of the refrigerantthrough the circuit is 0.45 kglmin calculate (i) the compressorpower, (ii) the heat rejected to the condenser cooling water in kJ/s,an (iii) the refrigerating effect in kJ/s. From tables page 12, NH,:2.68 bar, hg= 1430.58.57 bar, hf = 275.1 h supht 50" = 1597.2Mass flow of refrigerant--- - - 0.0075 kgls 60Enthalpy gain per kg of refrigerant in…arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY

composite-materials; Author: Tonya Coffey;https://www.youtube.com/watch?v=Vu6ik-bcKf4;License: Standard youtube license