(a)

The design of a three-plate moment connection of a

Answer to Problem 8.6.4P

Use a

1/8-in. fillet weld on both sides of the plate.

Use a

Explanation of Solution

Given:

Service dead-load moment = 42 ft-kips

Service live-load moment = 104 ft-kips

Service dead-load beam reaction = 8 kips

Service live-load beam reaction = 21 kips

Group A bearing type bolts

E70 electrodes

A992 steel- Beam and column

A36 steel- Plate material

Calculation:

Reaction:

Moment:

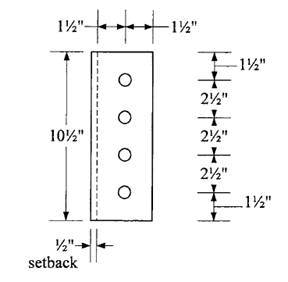

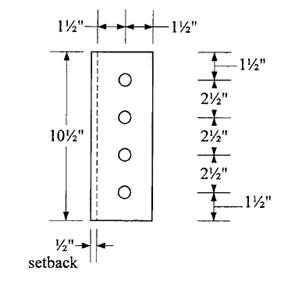

Web plate:

Neglect eccentricity.

Try 5/8-in. diameter bolts.

Assume that threads are in the plane of shear.

Shear capacity of one bolt is

Number of bolts required is

Try 4 bolts.

Determine plate thickness required for bearing. Assume that

Load resisted by each bolt =

Let

Try

Determine whether plate or beam web controls bearing. For the plate,

For the beam web,

Therefore, plate controls.

Check bearing strength assumption:

For the hole nearest the edge, minimum

Try

Therefore, use

For other bolts, minimum

Use

Therefore, use

Bearing controls over shear at each bolt location. Total strength is

Use four 5/8-in. diameter Group A bolts.

Determine plate thickness required for shear:

Shear yielding strength is

Let

Try

Check shear rupture strength:

Use hole diameter =

Check block shear:

Shear areas:

Tension area:

with an upper limit of

The nominal block shear strength is therefore 64.92 kips. The design block shear strength is

Use a

Connection of shear plate to column flange:

Use E70 electrodes

Minimum weld size, based on the plate thickness, is 1/8-in. try

Weld strength =

Base metal (plate) shear strength:

Yielding:

Rupture:

Total length required =

Use a continuous 1/8-in. fillet weld, both sides of plate.

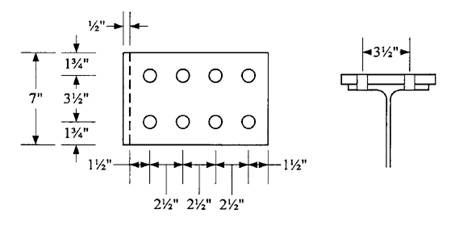

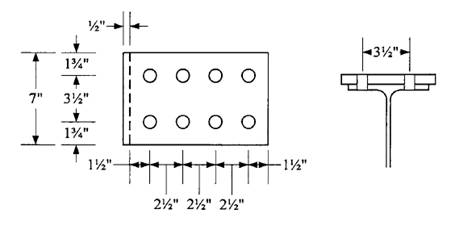

Flange plate:

From

Try 7/8-in. diameter bolts.

Assume that threads are in the plane of shear.

Number of bolts required for shear is

Try 8 bolts (4 pair)

Determine plate thickness required for bearing:

Minimum

Use

Minimum

Use

For the hole nearest the edge,

Therefore, use

For other bolts,

Therefore, use

Total connection strength =

Let

Design top flange plate as a tension connection element

Tension on gross area:

Required

Tension on net area:

Required

Try a plate width of

For gross area requirement,

For net area requirement,

Hole diameter =

Try a plate

Check compression in the bottom plate:

Assume that the plate acts as a fixed-end compression member between the end fastener and the weld. Use

For compression elements with

Therefore,

Check block shear on the plate using the dimensions and bolt layout shown.

Shear areas:

Tension area:

with an upper limit of

The nominal block shear strength is therefore 395.9 kips. The design block shear strength is

Check block shear strength of beam flange:

Transverse spacing = gauge distance = 3.5 in.

Transverse edge distance =

Longitudinal spacing and edge distance same as for plate.

Shear areas:

Tension area:

with an upper limit of

The nominal block shear strength is therefore 199.7 kips.

The design block shear strength is

Check beam for the effect of bolt holes in the tension flange:

The gross area of one flange is

The effective hole diameter is

Since

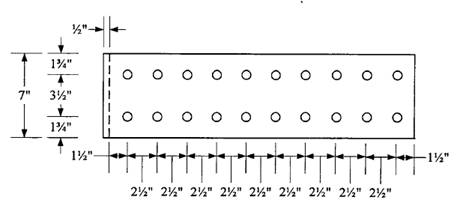

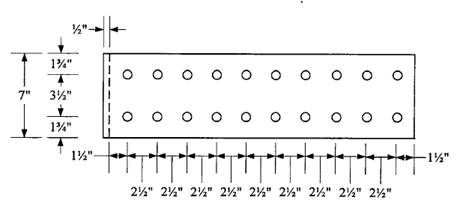

Try a smaller diameter bolt. Try ½-in. diameter bolts.

Normal shearing strength =

Number of bolts required for shear is

Try 20 bolts (10 pair)

Bearing and block shear will be satisfactory.

Check reduction in beam flange area:

Use a hole diameter =

Since

Plate length =

Conclusion:

Use a

(b)

The design of a three-plate moment connection of a

Answer to Problem 8.6.4P

Use a

1/8-in. fillet weld on both sides of the plate.

Use a

Explanation of Solution

Given:

Service dead-load moment = 42 ft-kips

Service live-load moment = 104 ft-kips

Service dead-load beam reaction = 8 kips

Service live-load beam reaction = 21 kips

Group A bearing type bolts

E70 electrodes

A992 steel- Beam and column

A36 steel- Plate material

Calculation:

Reaction:

Moment:

Web plate:

Neglect eccentricity.

Try 5/8-in. diameter bolts.

Assume that threads are in the plane of shear.

Shear capacity of one bolt is

Number of bolts required is

Try 4 bolts.

Determine plate thickness required for bearing. Assume that

Load resisted by each bolt =

Let

Try

Determine whether plate or beam web controls bearing. For the plate,

For the beam web,

Therefore, plate controls.

Check bearing strength assumption:

For the hole nearest the edge, minimum

Try

Therefore, use

For other bolts, minimum

Use

Therefore, use

Bearing controls over shear at each bolt location.

Total strength is

Use four 5/8-in. diameter Group A bolts.

Determine plate thickness required for shear:

Shear yielding strength is

Let

Try

Check shear rupture strength:

Use hole diameter =

Check block shear:

Shear areas:

Tension area:

with an upper limit of

The nominal block shear strength is therefore 64.92 kips. The design block shear strength is

Use a

Connection of shear plate to column flange:

Use E70 electrodes.

Minimum weld size, based on the plate thickness, is 1/8-in. try

Weld strength =

Base metal (plate) shear strength:

The allowable shear yield strength per unit length is

The base metal allowable shear rupture strength per unit length is

Total length required =

Use a continuous 1/8-in. fillet weld, both sides of plate.

Flange plate:

From

Try 7/8-in. diameter bolts.

Assume that threads are in the plane of shear.

Number of bolts required for shear is

Try 8 bolts (4 pair)

Determine plate thickness required for bearing:

Minimum

Use

Minimum

Use

For the hole nearest the edge,

Therefore, use

For other bolts,

Therefore, use

Total connection strength =

Let

Design top flange plate as a tension connection element

Tension on gross area:

Required

Tension on net area:

Required

Try a plate width of

For gross area requirement,

For net area requirement,

Hole diameter =

Try a plate

Check compression in the bottom plate:

Assume that the plate acts as a fixed-end compression member between the end fastener and the weld. Use

For compression elements with

Therefore,

Check block shear on the plate using the dimensions and bolt layout shown.

Shear areas:

Tension area:

with an upper limit of

The nominal block shear strength is therefore 395.9 kips. The design block shear strength is

Check block shear strength of beam flange:

Transverse spacing = gauge distance = 3.5 in.

Transverse edge distance =

Longitudinal spacing and edge distance same as for plate.

Shear areas:

Tension area:

with an upper limit of

The nominal block shear strength is therefore 199.7 kips.

The design block shear strength is

Check beam for the effect of bolt holes in the tension flange:

The gross area of one flange is

The effective hole diameter is

Since

Try a smaller diameter bolt. Try ½-in. diameter bolts.

Normal shearing strength =

Number of bolts required for shear is

Try 20 bolts (10 pair)

Bearing and block shear will be satisfactory.

Check reduction in beam flange area:

Use a hole diameter =

Since

Plate length =

Conclusion:

Use a

Want to see more full solutions like this?

Chapter 8 Solutions

Bundle: Steel Design, Loose-leaf Version, 6th + Mindtap Engineering, 1 Term (6 Months) Printed Access Card

- Consider a pool of saturated water at atmospheric pressure. The base of the pool is made of thick polished copper square plate of length 1 m. To generate steam, exhaust gas is flowing underneath and parallel to the base plate with velocity 3 m/s and average temperate of 1090°C. The bottom surface the plate is at constant temperature of 110°. Use the properties of air for exhaust gas. a) Determine the boiling heat transfer rate. b) Determine the temperature of the top surface of the plate. Comment on the results. c) Examine the impact of your assumptions on your solutions. (what will change if any of the assumptions is not valid?)arrow_forward-The axial deflection pipe in inches. -The lateral deflection of the beam in inches -The total deflection of the beam like structure in inches ? all to 4 sig figs AI did not help. as i input what i get im not sure if its a rounding error or what.arrow_forward1. For the foundation shown below: Qapp = 60 kips (Load obtained from structural engineer) 1.5 ft G.W.T. 3 ft Poorly Graded Sand (SP): Ym 115 pcf (above G.W.T.) Ysat 125 pcf (below G.W.T.) c' = 0, ' = 35° K Square footing, 4' x 4' Foundation Dimension Information: 1-ft x 1-ft square concrete column. 1-ft thick "foot" flanges. Yconc=150 pcf *Assume weight of reinforcing steel included in unit weight of concrete. *Assume compacted backfill weighs the same as in-situ soil. Assume this foundation is being designed for a warehouse that had a thorough preliminary soil exploration. Using the general bearing capacity equation: a. Calculate the gross applied bearing pressure, the gross ultimate bearing pressure, and determine if the foundation system is safe using a gross bearing capacity ASD approach. Please include the weight of the foundation, the weight of the backfill soil, and the effect of the uplift pressure caused by the presence of the water table in your bearing capacity…arrow_forward

- ٢٥ ٠٥:٤٠١٠ 2025 ChatGPT VivaCut Onet Puzzle مسلم X Excel JPG I❤> PDF Copilot Chat Bot PDF2IMG iLovePDF NokoPrint O.O StudyX ☑ W CapCut Candy Crush DeepSeek Word ☐ Saga 啡 AcadAl ل TikTokarrow_forwardRefer to the figure below. Given: L = 7 m, y = 16.7 kN/m², and ø' = 30°. L L3 ση Sand γ $' D T LA L σε σε IN P Sand 1. Calculate the theoretical depth of penetration, D. (Enter your answer to three significant figures.) D= m 2. Calculate the maximum moment. (Enter your answer to three significant figures.) Mmax kN-m/marrow_forwardWhy is it important for construction project managers to be flexible when dealing with the many variable factors that pop up in a project?arrow_forward

- What are some reasons for why a company would accelerate a construction project?arrow_forwardFor the design of a shallow foundation, given the following: Soil: ' = 20° c' = 52 kN/m² Unit weight, y = 15 kN/m³ Modulus of elasticity, E, = 1400 kN/m² Poisson's ratio, μs = 0.35 Foundation: L=2m B=1m Df = 1 m Calculate the ultimate bearing capacity. Use the equation: 1 - qu = c' NcFcs Fcd Fcc +qNqFqsFqdFqc + ½√BN√Fãs F√dƑxc 2 For '=20°, Nc = 14.83, N₁ = 6.4, and N₁ = 5.39. (Enter your answer to three significant figures.) qu = kN/m²arrow_forwardA 2.0 m wide strip foundation carries a wall load of 350 kN/m in a clayey soil where y = 15 kN/m³, c' = 5.0 kN/m² and ' = 23°. The foundation depth is 1.5 m. For ' = 23°: Nc = 18.05; N₁ = 8.66; Ny = = = 8.20. Determine the factor of safety using the equation below. qu= c' NcFcs FcdFci+qNqFqsFq 1 F + gd. 'qi 2 ·BN√· FF γί Ysyd F (Enter your answer to three significant figures.) FS =arrow_forward

Steel Design (Activate Learning with these NEW ti...Civil EngineeringISBN:9781337094740Author:Segui, William T.Publisher:Cengage Learning

Steel Design (Activate Learning with these NEW ti...Civil EngineeringISBN:9781337094740Author:Segui, William T.Publisher:Cengage Learning