Concept explainers

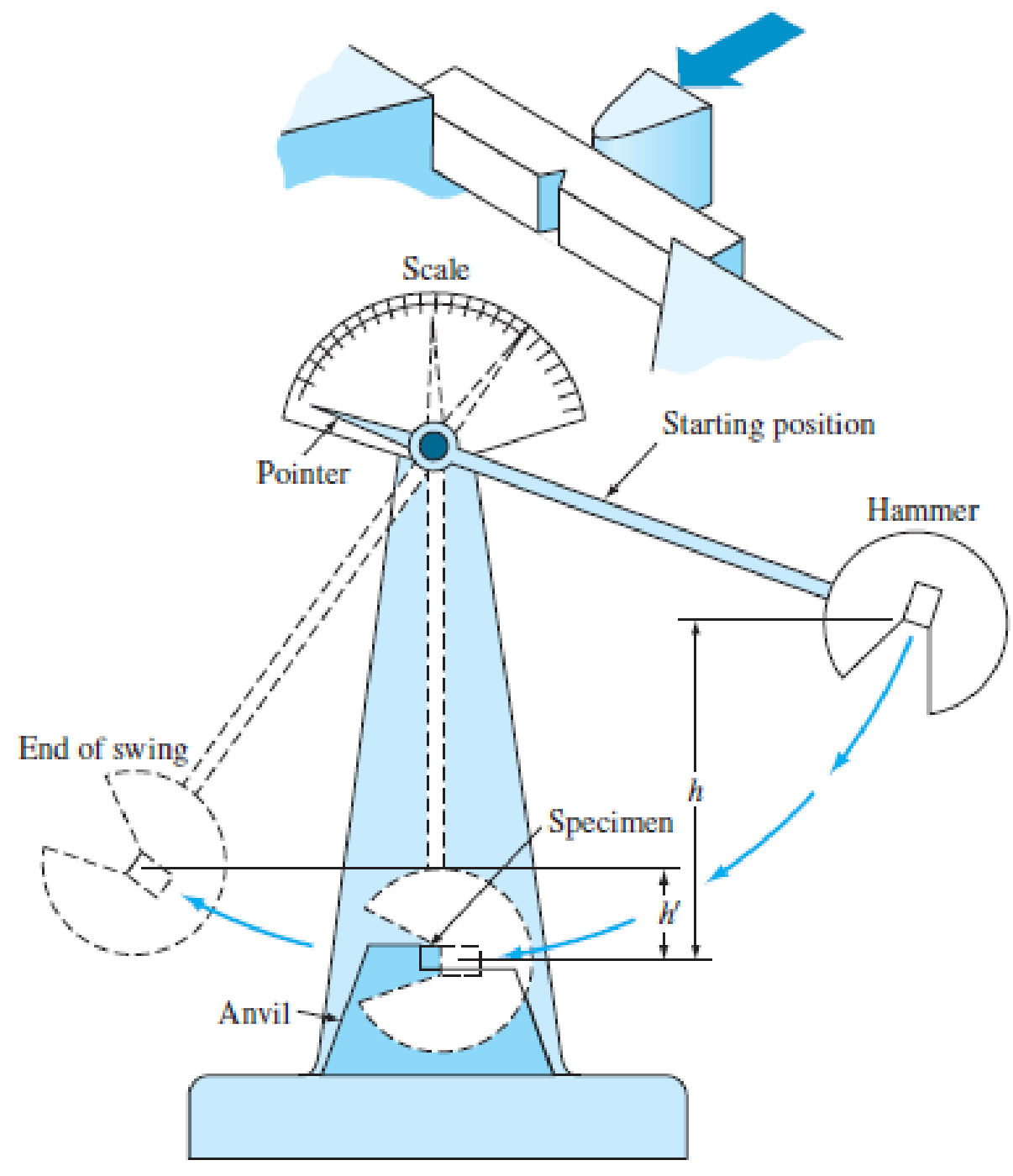

A Charpy V-notch specimen is tested by the impact-testing machine in Figure 7.9. In the test, the 10 kg hammer of arm-length 110 cm (measured from the fulcrum to the point of impact) is raised to 80° and then released. (a) What is the potential energy stored in the mass at this point? (b) After fracture of the specimen, the hammer swings to 45°. What is the potential energy at this point? (c) How much energy was expended in the fracture of the specimen? Hint: potential energy = mass × g × height.

Figure 7.9

Schematic drawing of a standard impact-testing apparatus.

(a)

The potential energy stored in the mass at the point of impact when the hammer raised to

Answer to Problem 43SEP

The potential energy stored in the mass at the point of impact is

Explanation of Solution

Write the expression for Potential energy stored in the hammer is,

Here, mass of hammer is

Conclusion:

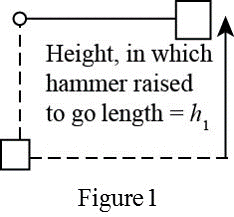

Below figure represent the new position of the hammer when hammer is raised to

From Figure-1, when the hammer is rotated to an angle of

Substitute

Thus, the potential energy stored in the mass at the point of impact is

(b)

The potential energy at the point of impact when the hammer swing to

Answer to Problem 43SEP

The potential energy stored in the mass at the point of impact is

Explanation of Solution

Write the expression height of impact when hammer is raised

Here, height of impact is

Write the expression for Potential energy stored in the hammer is,

Here, mass of hammer is

Conclusion:

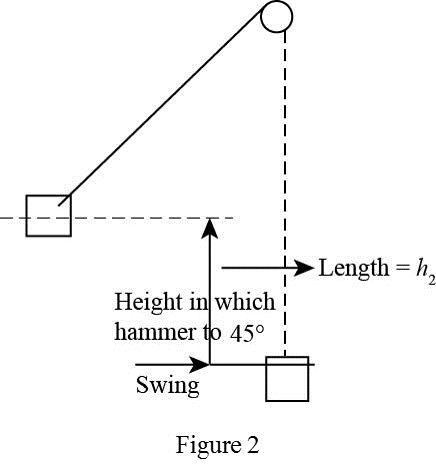

Below figure represent the new position of the hammer when hammer is swing to

From Figure-2, when the hammer is swing to an angle of

Substitute

Substitute

Thus, the potential energy stored in the mass at the point of impact is

(c)

The amount of energy expended in the fracture of the specimen.

Answer to Problem 43SEP

The amount of energy expended in the fracture of the specimen is

Explanation of Solution

Write the expression of energy expended in the fracture of the specimen is,

Conclusion:

Substitute

The amount of energy expended in the fracture of the specimen is

Want to see more full solutions like this?

Chapter 7 Solutions

Foundations of Materials Science and Engineering

Additional Engineering Textbook Solutions

Fluid Mechanics: Fundamentals and Applications

Thermodynamics: An Engineering Approach

Mechanics of Materials (10th Edition)

Vector Mechanics for Engineers: Statics and Dynamics

Electric Circuits. (11th Edition)

Java: An Introduction to Problem Solving and Programming (8th Edition)

- Copyright 2013 Pearson Education, publishing as Prentice Hall 2. Determine the force that the jaws J of the metal cutters exert on the smooth cable C if 100-N forces are applied to the handles. The jaws are pinned at E and A, and D and B. There is also a pin at F. E 400 mm 15° D B 30 mm² 80 mm/ 20 mm 15° $15° 20 mm 400 mm 15° 100 N 100 N 15°arrow_forwardDraw for it make a match which directionarrow_forwardQ.1) Block A is connected to block B by a pulley system as shown. The weights of blocks A and B are 100 lbs and 70 lbs, respectively. Assume negligible friction between the rope and all pulleys as well as between block B and the incline and neglect the mass of all pulleys and cables. Determine the angle 0 required to keep the system in equilibrium. (At least two FBDs must be drawn for full credit) B Ꮎ 000arrow_forward

- pls solvearrow_forward+1. 0,63 fin r= 0.051 P The stepped rod in sketch is subjected to a tensile force that varies between 4000 and 7000 lb. The rod has a machined surface finish everywhere except the shoulder area, where a grinding operation has been performed to improve the fatigue resistance of the rod. Using a 99% probability of survival, determine the safety factor for infinite life if the rod is made of AISI 1080 steel, quenched and tempered at 800°c Use the Goodman line. Does the part fail at the fillet? Explainarrow_forwardSolve this problem and show all of the workarrow_forward

- I need drawing solution,draw each one by one no Aiarrow_forwardQu. 17 Compute linear density values for [100] for silver (Ag). Express your answer in nm''. . Round off the answer to three significant figures. Qu. 18 Compute linear density value for [111] direction for silver (Ag). Express your answer in nm'. Round off the answer to three significant figures. Qu. 19 Compute planar density value for (100) plane for chromium (Cr). Express your answer in nm?. Round off the answer to two significant figures. Qu. 20 Compute planar density value for (110) plane for chromium (Cr). Express your answer in nm ≥ to four significant figures. show all work please in material engineeringarrow_forward3-142arrow_forward

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY