ELEM.PRIN.OF CHEMICAL...ABRIDGED (LL)

4th Edition

ISBN: 9781119540632

Author: FELDER

Publisher: WILEY

expand_more

expand_more

format_list_bulleted

Concept explainers

Question

Chapter 6, Problem 6.96P

Interpretation Introduction

Interpretation:

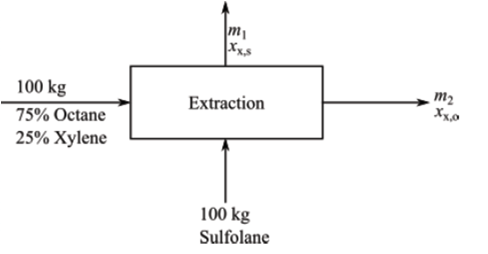

To determine amount of xylene transfers to the sulfolane phase.

Concept introduction:

Extraction is a process of separating different components of a mixture based on their solubility. When the vapor pressure of different components is of the same range, they cannot be separated by the distillation column. Extraction is used for the similar boiling point range compounds.

Flowchart for the process is as follows:

Expert Solution & Answer

Want to see the full answer?

Check out a sample textbook solution

Students have asked these similar questions

solve for both a stripper and absorber. take the equilibrium data given to just be a y=x line

solve all parts pls

please solve all parts

Chapter 6 Solutions

ELEM.PRIN.OF CHEMICAL...ABRIDGED (LL)

Ch. 6 - Ten mL of pure liquid water in a cylinder with a...Ch. 6 - A quantity of methyl acetate is placed in an open,...Ch. 6 - Ethyl alcohol has a vapor pressure of 20.0 mm Hg...Ch. 6 - Prob. 6.4PCh. 6 - Prob. 6.5PCh. 6 - Prob. 6.6PCh. 6 - Prob. 6.7PCh. 6 - Prob. 6.8PCh. 6 - Prob. 6.9PCh. 6 - Prob. 6.10P

Ch. 6 - Prob. 6.11PCh. 6 - Prob. 6.12PCh. 6 - Prob. 6.13PCh. 6 - Air at 50% relative humidity is cooled...Ch. 6 - Prob. 6.15PCh. 6 - Prob. 6.16PCh. 6 - Air at 90°C and 1.00 atm (absolute) contains 10.0...Ch. 6 - When fermentation units are operated with high...Ch. 6 - When you step out of a shower, the temperature in...Ch. 6 - A fuel cell is an electrochemical device in which...Ch. 6 - Prob. 6.21PCh. 6 - Prob. 6.22PCh. 6 - Prob. 6.23PCh. 6 - Prob. 6.24PCh. 6 - Prob. 6.25PCh. 6 - Prob. 6.26PCh. 6 - Prob. 6.27PCh. 6 - Prob. 6.28PCh. 6 - An air conditioner is designed to bring 10.000...Ch. 6 - Prob. 6.30PCh. 6 - Prob. 6.31PCh. 6 - Prob. 6.32PCh. 6 - A gas stream containing 40.0 mole% hydrogen, 35.0%...Ch. 6 - Prob. 6.34PCh. 6 - In the manufacture of an active pharmaceutical...Ch. 6 - Prob. 6.36PCh. 6 - In the ?nal stage of the manufacturing process...Ch. 6 - Prob. 6.38PCh. 6 - A fuel gas containing methane and ethane is burned...Ch. 6 - A mixture of propane and butane is burned with...Ch. 6 - An important parameter in the design of gas...Ch. 6 - A liquid stream consisting of 12.5 mole% n-butane...Ch. 6 - Nitric acid is a chemical intermediate primarily...Ch. 6 - Prob. 6.44PCh. 6 - Sulfur trioxide (SO3) dissolves in and reacts with...Ch. 6 - State whether you would use Raoult’s law or Henrys...Ch. 6 - A gas containing nitrogen, benzene, and toluene is...Ch. 6 - Prob. 6.48PCh. 6 - Prob. 6.49PCh. 6 - A conelation for methane solubility in...Ch. 6 - Prob. 6.51PCh. 6 - The constituent partial pressures of a gas in...Ch. 6 - Prob. 6.53PCh. 6 - Prob. 6.54PCh. 6 - Prob. 6.55PCh. 6 - Prob. 6.56PCh. 6 - Prob. 6.57PCh. 6 - Prob. 6.58PCh. 6 - Nitrogen is bubbled through a liquid mixture that...Ch. 6 - Prob. 6.60PCh. 6 - Prob. 6.61PCh. 6 - Prob. 6.62PCh. 6 - The feed to a distillation column (sketched below)...Ch. 6 - Prob. 6.64PCh. 6 - Prob. 6.65PCh. 6 - Prob. 6.66PCh. 6 - Prob. 6.67PCh. 6 - Prob. 6.68PCh. 6 - Prob. 6.69PCh. 6 - Prob. 6.70PCh. 6 - A methanol-water feed stream is introduced to a...Ch. 6 - Prob. 6.72PCh. 6 - In this problem you will use a spreadsheet to...Ch. 6 - Prob. 6.74PCh. 6 - Prob. 6.75PCh. 6 - Prob. 6.76PCh. 6 - Acetaldehyde is synthesized by the catalytic...Ch. 6 - Dehydration of natural gas is necessary to prevent...Ch. 6 - A two-unit process is used to separate H2S from a...Ch. 6 - Prob. 6.80PCh. 6 - Prob. 6.81PCh. 6 - Prob. 6.82PCh. 6 - Prob. 6.83PCh. 6 - A solution containing 100 lbm KNO3/100 Ibm H2O at...Ch. 6 - A 10.0 wt% aqueous solution of sodium chloride is...Ch. 6 - Potassium dichromate (K2Cr2O7) is to be recovered...Ch. 6 - Prob. 6.87PCh. 6 - Prob. 6.88PCh. 6 - Sodium bicarbonate is synthesized by reacting...Ch. 6 - An ore containing 90 wt% MgSO4(H2O and the balance...Ch. 6 - An aqueous waste stream leaving a process contains...Ch. 6 - A solution of diphenyl (MW = 154.2) in benzene is...Ch. 6 - An aqueous solution of urea (MW = 60.06) freezes...Ch. 6 - Prob. 6.94PCh. 6 - Derive Equation 6.54 for the boiling-point...Ch. 6 - Prob. 6.96PCh. 6 - A stream of 5.00 wt% oleic acid in cottonseed oil...Ch. 6 - Benzene and hexane are being considered as...Ch. 6 - Acetone is lo be extracted with n-hexane from a...Ch. 6 - Prob. 6.100PCh. 6 - Prob. 6.101PCh. 6 - Five kilograms of a 30 wt% acetone70% water...Ch. 6 - An aqueous acetone solution is fed at a rate of...Ch. 6 - Prob. 6.104PCh. 6 - Prob. 6.105PCh. 6 - Air at 25°C and 1 atm with a relative humidity of...Ch. 6 - Prob. 6.107PCh. 6 - Prob. 6.108PCh. 6 - Various amounts of activated carbon were added to...

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, chemical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Homework 8 View Policies Show Attempt History Current Attempt in Progress Question 3 of 5 Entering Steam > > Check table lookups for correct values. Check significant figures. Check unit conversions. Calculate the required flow rate of the entering steam in m³/min. 0.00132 m³/min eTextbook and Media Hint 0/1 Assistance Used Determine the specific enthalpy change of each stream first. Then use the known flow rate of the methanol to calculate the steam flow rate. Save for Later Heat Transferred × Check units and significant figures. Calculate the rate of heat transfer from the water to the methanol (kW). i 44.5 kW Hint Don't forget to convert minutes to seconds. Save for Later Attempts: 3 of 5 used Submit Answer Assistance Used Attempts: 2 of 5 used Submit Answerarrow_forward← Homework 8 View Policies Show Attempt History Current Attempt in Progress A liquid mixture of benzene and toluene containing 52.0 wt% benzene at 100.0 °C and pressure Po atm is fed at a rate of 32.5 m³/h into a heated flash tank maintained at a pressure Ptank Material Balances Correct. 0.67/1 === Attempts: 1 of 5 used Calculate Ptank (atm), the mole fraction of benzene in the vapor, and the molar flow rates of the liquid and vapor products. Ptank .544 atm Ybz .657 mol benzene/mol vapor product nvapor 55.8 mol/s nliquid 37.6 mol/s Hint GO Tutorial Energy Balance Check heat capacities. Calculate the required heat input rate in kilowatts. i 0.447 kW Hint GO Tutorial Save for Later Assistance Used Attempts: 2 of 5 used Assistance Used Attempts: 1 of 5 used Submit Answerarrow_forwardView Policies Show Attempt History Current Attempt in Progress Homework 8 A stream of pure cyclopentane vapor flowing at a rate of 1650 L/s at 190.0°C and 1 atm enters a cooler in which 50.0% of the feed is condensed at constant pressure. Question 4 of 5 Correct What is the temperature at the condenser outlet? 49.3 °℃ eTextbook and Media Hint Enthalpy Table Your Answer Correct Answer (Used) 0.67/1 E Attempts: 1 of 5 used Prepare and fill in an inlet-outlet enthalpy table. Use a reference state of liquid cyclopentane at the boiling point. In T = 190.0°C Out T=49.3°C Substance n (mol/s) Ĥ (kJ/mol) n (mol/s) Ĥ (kJ/mol) C5H10(1) 0.0 21.708 0.0 C5H10(V) 43.416 43.687 21.708 27.30 Heat Check significant figures and sign. Calculate the required cooling rate (a positive number). ! kW Hint Save for Later Attempts: 3 of 5 used Submit Answerarrow_forward

- View Policies Show Attempt History Current Attempt in Progress A liquid mixture of benzene and toluene containing 52.0 wt% benzene at 100.0 °C and pressure Po atm is fed at a rate of 32.5 m³/h into a heated flash tank maintained at a pressure Ptank Your answer is partially correct. 1.312 atm Assistance Used 0.58/1 Calculate Ptank (atm), the mole fraction of benzene in the vapor, and the molar flow rates of the liquid and vapor products. Ptank i atm .657 Ybz mol benzene/mol vapor product nvapor 55.8 mol/s nliquid 37.6 mol/s Hint GO Tutorial Save for Later Energy Balance Calculate the required heat input rate in kilowatts. i kW GO Tutorial Save for Later Assistance Used Attempts: 1 of 5 used Submit Answer Assistance Used Attempts: 0 of 5 used Submit Answerarrow_forwardView Policies Show Attempt History Current Attempt in Progress Saturated steam at 342.1°C is used to heat a countercurrently flowing stream of methanol vapor from 70.0°C to 321.7°C in an adiabatic heat exchanger. The flow rate of the methanol is 5530 standard liters per minute, and the steam condenses and leaves the heat exchanger as liquid water at 95.0°C. Physical Property Tables Entering Steam Homework 8 Question 3 of 5 Check unit conversions. Calculate the required flow rate of the entering steam in m³/min. 0.0165 m³/min eTextbook and Media Hint Save for Later Heat Transferred * Check units and significant figures. Calculate the rate of heat transfer from the water to the methanol (kW). i 58.7 kW Hint Save for Later 0/1 EE Attempts: 1 of 5 used Submit Answer Attempts: 1 of 5 used Submit Answerarrow_forwardheat and mass transferarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education

Introduction to Chemical Engineering Thermodynami...Chemical EngineeringISBN:9781259696527Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark SwihartPublisher:McGraw-Hill Education Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY

Elementary Principles of Chemical Processes, Bind...Chemical EngineeringISBN:9781118431221Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. BullardPublisher:WILEY Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Elements of Chemical Reaction Engineering (5th Ed...Chemical EngineeringISBN:9780133887518Author:H. Scott FoglerPublisher:Prentice Hall

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning

Industrial Plastics: Theory and ApplicationsChemical EngineeringISBN:9781285061238Author:Lokensgard, ErikPublisher:Delmar Cengage Learning Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Unit Operations of Chemical EngineeringChemical EngineeringISBN:9780072848236Author:Warren McCabe, Julian C. Smith, Peter HarriottPublisher:McGraw-Hill Companies, The

Introduction to Chemical Engineering Thermodynami...

Chemical Engineering

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind...

Chemical Engineering

ISBN:9781118431221

Author:Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:WILEY

Elements of Chemical Reaction Engineering (5th Ed...

Chemical Engineering

ISBN:9780133887518

Author:H. Scott Fogler

Publisher:Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:9781285061238

Author:Lokensgard, Erik

Publisher:Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:9780072848236

Author:Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:McGraw-Hill Companies, The