Concept explainers

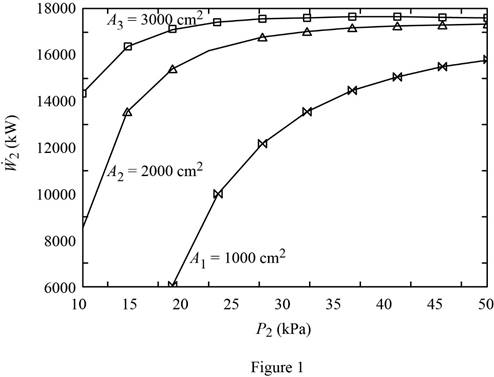

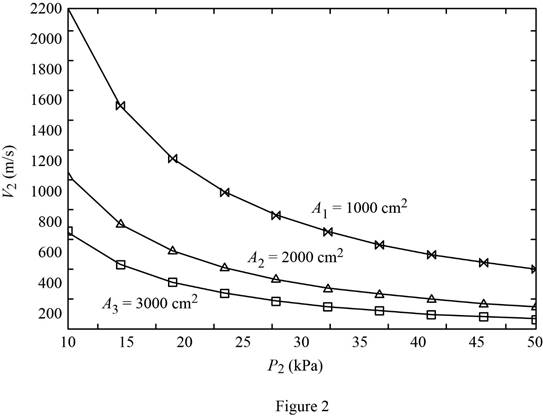

Reconsider Prob. 5–178. Using appropriate software, investigate the effects of turbine exit area and turbine exit pressure on the exit velocity and power output of the turbine. Let the exit pressure vary from 10 to 50 kPa (with the same quality), and let the exit area vary from 1000 to 3000 cm2. Plot the exit velocity and the power outlet against the exit pressure for the exit areas of 1000, 2000, and 3000 cm2, and discuss the

results.

5–178 Steam enters a turbine steadily at 7 MPa and 600°C with a velocity of 60 m/s and leaves at 25 kPa with a quality of 95 percent. A heat loss of 20 kJ/kg occurs during the process. The inlet area of the turbine is 150 cm2, and the exit area is 1400 cm2. Determine (a) the mass flow rate of the steam, (b) the exit velocity, and (c) the power output.

Plot the exit pressure against power output of turbine and exit pressure against exit velocity for varying pressure from

Answer to Problem 179RP

The plot for the exit pressure against power output of turbine and exit pressure against exit velocity for varying pressure from

Explanation of Solution

The turbine operates steadily. Hence, the inlet and exit mass flow rates are equal.

Write the formula for inlet mass flow rate.

Here, the cross-sectional area is

At inlet:

The steam is at the state of superheated condition.

Refer Table A-6, “Superheated water”.

Obtain the inlet enthalpy

The turbine operates steadily. Hence, the inlet and exit mass flow rates are equal.

Write the formula for exit mass flow rate.

Here, the cross-sectional area is

Rearrange the Equation (II) to obtain exit velocity

At exit:

Consider the exit pressure

The steam is with the quality of

Write the formula for exit enthalpy

Write the formula for exit specific volume

Here, the enthalpy is

Refer Table A-5, “Saturated water—Pressure table”.

Obtain the following corresponding to the pressure of

Consider the steam flows at steady state. Hence, the inlet and exit mass flow rates are equal.

Write the energy rate balance equation for one inlet and one outlet system.

Here, the rate of heat transfer is

The refrigerant flows at steady state through the compressor. Hence, the rate of change in net energy of the system becomes zero.

Heat loss occurs at the rate of

The Equations (VI) reduced as follows to obtain the work output

Here,

Rewrite the Equation (VII) as follows.

Conclusion:

Substitute

Substitute

Equation (V).

Substitute

Consider the exit area

Substitute

Equation (III).

Substitute

The exit velocity

Using excel spread sheet, the exit velocity

| S.No. | |||

| 1 | 10 | 2253.540216 | –22171.1196 |

| 2 | 15 | 1539.230498 | –514.857057 |

| 3 | 20 | 1174.871104 | 7295.806083 |

| 4 | 25 | 952.9435377 | 10965.91684 |

| 5 | 30 | 803.2150134 | 12968.62817 |

| 6 | 40 | 613.4390747 | 14943.44488 |

| 7 | 50 | 497.7670121 | 15822.49054 |

Table 1

Similarly, the exit velocity

| S.No. | |||

| 1 | 10 | 1126.770108 | 8623.292217 |

| 2 | 15 | 769.6152491 | 13851.56455 |

| 3 | 20 | 587.435552 | 15665.73428 |

| 4 | 25 | 476.4717689 | 16472.41662 |

| 5 | 30 | 401.6075067 | 16880.6829 |

| 6 | 40 | 306.7195374 | 17225.27947 |

| 7 | 50 | 248.883506 | 17324.918 |

Table 2

Similarly, the exit velocity

| S.No. | |||

| 1 | 10 | 751.180072 | 14325.96107 |

| 2 | 15 | 513.0768327 | 16512.01299 |

| 3 | 20 | 391.6237013 | 17215.72099 |

| 4 | 25 | 317.6478459 | 17492.1388 |

| 5 | 30 | 267.7383378 | 17605.13749 |

| 6 | 40 | 204.4796916 | 17647.84143 |

| 7 | 50 | 165.9223374 | 17603.1453 |

Table 3

Refer Table 1, 2, and 3.

Plot the graph for the exit pressure

Refer Table 1, 2, and 3.

Plot the graph for the exit pressure

Want to see more full solutions like this?

Chapter 5 Solutions

EBK THERMODYNAMICS: AN ENGINEERING APPR

Additional Engineering Textbook Solutions

Vector Mechanics For Engineers

Mechanics of Materials (10th Edition)

BASIC BIOMECHANICS

Database Concepts (8th Edition)

Electric Circuits. (11th Edition)

Thermodynamics: An Engineering Approach

- 4. Consider the rectangulan 2535 Let 16 a and section discussed 977b + class. in ie make a M thin" rectangle, Can you you show that Q = Go {a² = x² } . Imax = 2 Ga ты J =arrow_forward1. Consider a circular shaft in torsion that of radius r=b has a key way as shown, circle of radius a Let us try the solution x₁ (5,0) = k (6² = r²) (1- 2 awso 1.1 Does this solve the problem for the stres rer 1,2 Solve for is and 23.arrow_forward3. - a For an elliptical cross that the tangent to section resultant shear can you s stress is show ellipse with the same 24 i ratio of eccentricity, in passes through to point alb that in question, it + Parrow_forward

- 2. Consider the rod with an elliptical that strain 4 a Cross secton considered in class, Integrate the was displacement displacements, relations to obtain thearrow_forwardPlease answer Oxygen at 300 kPa and 90°C flowing at an average velocity of 3 m/s is expanded in an adiabatic nozzle. What is the maximum velocity of the oxygen at the outlet of this nozzle when the outlet pressure is 60 kPa? Use the table containing the ideal gas specific heats of various common gases. The maximum velocity of the oxygen at the outlet of this nozzle is 532.5 Numeric ResponseEdit Unavailable. 532.5 incorrect.m/s.arrow_forwardA container filled with 70 kg of liquid water at 95°C is placed in a 90-m3 room that is initially at 12°C. Thermal equilibrium is established after a while as a result of heat transfer between the water and the air in the room. Assume the room is at the sea level, well sealed, and heavily insulated. NOTE: This is a multi-part question. Once an answer is submitted, you will be unable to return to this part. Determine the amount of heat transfer between the water and the air in the room. The amount of heat transfer between the water and the air in the room is kJ.arrow_forward

- A strain gauge rosette that is attached to the surface of a stressed component gives 3 readings (ɛa = A, b = B, &c = C). If the strain gauge rosette is of the D° type (indicating the angle between each of the gauges), construct a Mohr's Strain Circle overleaf. You should assume that gauge A is aligned along the x-axis. Using the Mohr's Strain Circle calculate the: (i) principal strains (ε1, 2)? (ii) principal angles (1, 2)? You should measure these anticlockwise from the y-axis. (iii) maximum shear strain in the plane (ymax)?arrow_forwardQ1. If the yield stress (σy) of a material is 375MPa, determine whether yield is predicted for the stresses acting on both the elements shown below using: (a) Tresca Criterion (b) Von Mises Criterion P Element A R S Element B Note: your values for P (vertical load on Element A) should be negative (i.e. corresponding to a compressive vertical load).arrow_forwardQ. After a puncture a driver is attempting to remove a wheel nut by applying a force of P KN to one end of a wheel brace as shown in Fig. 1. In cross-section the brace is a hollow steel tube (see section aa) of internal diameter r mm and external diameter q mm. wheel nut n Position S P m r q Section aa Fig, 1 (a) Calculate (i) the twisting moment, (ii) the bending moment, and (iii) the shear force in the brace at position S due to the applied load P. (b) Calculate (i) the shear stress due to twisting, and (ii) the bending stress at position S. Note that the shear force will not produce any shear stress at S. (c) Calculate the maximum shearing stress in the brace at position S using the Maximum Shear Stress Criterion. 2 Mechanics of Materials 2 Tutorials Portfolio: Exercise 5 (d) If the maximum permissible shear stress in the steel is 200 MPa, determine the maximum torque that can be applied by the brace without the risk of failure at S.arrow_forward

- Calculate the first 5 Fourier series coefficients (A0-4 and B1-5 ) for the estimated R wave.arrow_forwardRefrigerant-134a is expanded isentropically from 600 kPa and 70°C at the inlet of a steady-flow turbine to 100 kPa at the outlet. The outlet area is 1 m2, and the inlet area is 0.5 m2. Calculate the inlet and outlet velocities when the mass flow rate is 0.65 kg/s. Use the tables for R-134a. The inlet velocity is m/s. The outlet velocity is m/s.arrow_forwardA container filled with 70 kg of liquid water at 95°C is placed in a 90-m3 room that is initially at 12°C. Thermal equilibrium is established after a while as a result of heat transfer between the water and the air in the room. Assume the room is at the sea level, well sealed, and heavily insulated. NOTE: This is a multi-part question. Once an answer is submitted, you will be unable to return to this part. Determine the final equilibrium temperature. Use the table containing the ideal gas specific heats of various common gases. The final equilibrium temperature is °C.arrow_forward

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY