Precision Machining Technology (MindTap Course List)

2nd Edition

ISBN: 9781285444543

Author: Peter J. Hoffman, Eric S. Hopewell, Brian Janes

Publisher: Cengage Learning

expand_more

expand_more

format_list_bulleted

Concept explainers

Textbook Question

Chapter 3.1, Problem 7RQ

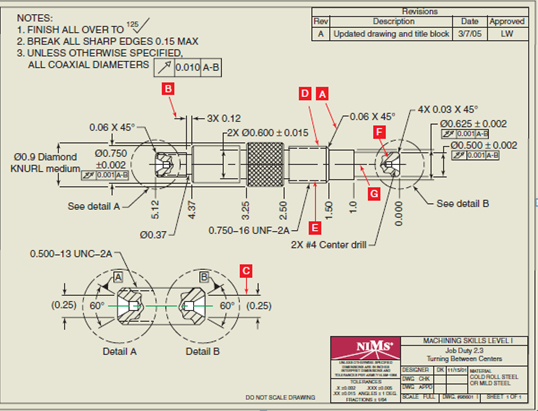

Identify the line types labeled in the print located on the following page:

- a. __________

- b. __________

- c. __________

- d. __________

- e. __________

- f. __________

- g. __________

Expert Solution & Answer

Trending nowThis is a popular solution!

Students have asked these similar questions

Question 2

You are an engineer working in the propulsion team for a supersonic civil transport

aircraft driven by a turbojet engine, where you have oversight of the design for the

engine intake and the exhaust nozzle, indicated in Figure Q2a. The turbojet engine can

operate when provided with air flow in the Mach number range, 0.60 to 0.80. You are

asked to analyse a condition where the aircraft is flying at 472 m/s at an altitude of

14,000 m. For all parts of the question, you can assume that the flow path of air through

the engine has a circular cross section.

(a)

← intake

normal

shock

472 m/s

A B

(b)

50 m/s

H

472 m/s

B

engine

altitude: 14,000 m

exhaust nozzle

E

F

exit to

atmosphere

diameter: DE = 0.30 m

E

F

diameter: DF = 0.66 m

Figure Q2: Propulsion system for a supersonic aircraft.

a) When the aircraft is at an altitude of 14,000 m, use the International Standard

Atmosphere in the Module Data Book to state the local air pressure and tempera-

ture. Thus show that the aircraft speed…

يكا

- put 96**

I need a detailed drawing with

explanation

or in wake, and the top edge of

im below the free surface of the water. Determine the hydrothed if

hydrostatic on the

Plot the displacement diagram for a cam with roller follower of diameter 10 mm. The required

motion is as follows;

1- Rising 60 mm in 135° with uniform acceleration and retardation motion.

2- Dwell 90°

3- Falling 60 mm for 135° with Uniform acceleration-retardation motion.

Then design the cam profile to give the above displacement diagram if the minimum circle

diameter of the cam is 50 mm.

=--20125

7357

750 X 2.01

You are working as an engineer in a bearing systems design company. The flow of

lubricant inside a hydrodynamic bearing (µ = 0.001 kg m¯¹ s¯¹) can be approximated

as a parallel, steady, two-dimensional, incompressible flow between two parallel plates.

The top plate, representing the moving part of the bearing, travels at a constant speed,

U, while the bottom plate remains stationary (Figure Q1). The plates are separated by

a distance of 2h = 1 cm and are W = 20 cm wide. Their length is L = 10 cm. By

applying the above approximations to the Navier-Stokes equations and assuming that

end effects can be neglected, the horizontal velocity profile can be shown to be

U

y = +h

У

2h = 1 cm

1

x1

y=-h

u(y)

=

1 dP

2μ dx

-y² + Ay + B

moving plate

-

U

stationary plate

2

I2

L = 10 cm

Figure Q1: Flow in a hydrodynamic bearing. The plates extend a width, W = 20 cm,

into the page.

(a) By considering the appropriate boundary conditions, show that the constants take

the following forms:

A =

U

2h

U

1 dP…

Chapter 3 Solutions

Precision Machining Technology (MindTap Course List)

Ch. 3.1 - Information such as tolerances and scale can be...Ch. 3.1 - What view of a drawing usually shows the most...Ch. 3.1 - Prob. 3RQCh. 3.1 - The line type used to show edges of an object that...Ch. 3.1 - What line type is used to show edges of an object...Ch. 3.1 - What two line types work together to show sizes on...Ch. 3.1 - Identify the line types labeled in the print...Ch. 3.1 - Define and briefly describe the following...Ch. 3.1 - A dimension listed on an engineering drawing is...Ch. 3.1 - List and briefly describe the three types of...

Ch. 3.1 - Briefly describe the difference between a...Ch. 3.1 - The relationship between sizes of mating parts is...Ch. 3.1 - What does GDT stand for?Ch. 3.1 - A plane used as a reference for dimensions is...Ch. 3.1 - A GDT symbol and the amount of tolerance are shown...Ch. 3.1 - What are the five categories of symbols used in...Ch. 3.1 - Briefly explain the benefit of a position...Ch. 3.2 - Prob. 1RQCh. 3.2 - What is the purpose of layout fluid (dye)?Ch. 3.2 - Prob. 3RQCh. 3.2 - Briefly define a scriber and its use.Ch. 3.2 - What two angles can be laid out with the...Ch. 3.2 - What two tasks can a divider be used to perform?Ch. 3.2 - What safety precautions should be observed when...Ch. 3.2 - What would the divider setting be to scribe a...Ch. 3.2 - What would the divider setting be to scribe an arc...Ch. 3.2 - Prob. 10RQCh. 3.2 - Prob. 11RQCh. 3.2 - Briefly describe the use of a surface gage.Ch. 3.3 - What are three safety rules to observe when using...Ch. 3.3 - List three types of screwdriver tips.Ch. 3.3 - What is the advantage of using slip joint pliers?Ch. 3.3 - What is an advantage of using locking pliers?Ch. 3.3 - What are two uses for a ball peen hammer?Ch. 3.3 - What is the advantage of a soft face hammer?Ch. 3.3 - In what situation would a box-end wrench be chosen...Ch. 3.3 - List two precautions to observe when using...Ch. 3.3 - What is one method of preventing damage to work...Ch. 3.3 - List three safety precautions to be observed when...Ch. 3.3 - In which direction should hacksaw blade teeth...Ch. 3.3 - List two safety precautions that should be...Ch. 3.3 - Will a single-cut or a double-cut file remove...Ch. 3.3 - Will a single-cut or a double-cut file produce a...Ch. 3.3 - ___________ and _________ are two common filing...Ch. 3.3 - What tool is used to clean a file?Ch. 3.3 - What are the two forms of abrasives used in...Ch. 3.4 - Sawing machines can be divided into roughly four...Ch. 3.4 - The vertical band saw is particularly useful, as...Ch. 3.4 - The horizontal band saw is ideal for cutting...Ch. 3.4 - Cutting action on the power hacksaw is very...Ch. 3.4 - List three safety precautions to observe when...Ch. 3.4 - Briefly describe the process to prepare for...Ch. 3.4 - List three safety precautions to observe when...Ch. 3.4 - What type of band saw blade has HSS teeth welded...Ch. 3.4 - How many saw teeth should be engaged in the...Ch. 3.4 - Name the three different types of tooth patterns.Ch. 3.4 - What are the three types of tooth set and why is...Ch. 3.4 - The slot created in a workpiece by the saw blade...Ch. 3.4 - Explain how to use a push stick.Ch. 3.4 - Saws should be ____________ _____________ when a...Ch. 3.4 - Saw guides should be mounted ________ above the...Ch. 3.4 - Why must a band saw blade be annealed after...Ch. 3.4 - Why does a band saw blade need to be ground after...Ch. 3.4 - Clearance between the vertical band saw guides and...Ch. 3.4 - Band saw cutting speeds are given in _________.Ch. 3.5 - What is the main benefit of offhand abrasive...Ch. 3.5 - What type of metals should not be ground on a...Ch. 3.5 - Which wheel is finer, a 60 grit or a 36 grit?Ch. 3.5 - If a grinder runs at 3400 RPM and you have a wheel...Ch. 3.5 - How is a ring test performed?Ch. 3.5 - Why is it necessary to have blotters on both sides...Ch. 3.5 - The maximum distance that a spark breaker and tool...Ch. 3.5 - When should a grinding wheel be dressed?Ch. 3.5 - Where should you stand when using a grinder?Ch. 3.6 - Define drilling.Ch. 3.6 - What factors might determine when a hole must be...Ch. 3.6 - Prob. 3RQCh. 3.6 - Explain the purpose of a counterbore.Ch. 3.6 - What is the purpose of the pilot on a counterbore?Ch. 3.6 - What should be done as a drill nears the...Ch. 3.6 - Define thread as it relates to benchwork.Ch. 3.6 - Explain the major diameter of a thread.Ch. 3.6 - What is the TPI of a -20 thread?Ch. 3.6 - Name two types of tap wrenches.

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Question 2 You are an engineer working in the propulsion team for a supersonic civil transport aircraft driven by a turbojet engine, where you have oversight of the design for the engine intake and the exhaust nozzle, indicated in Figure Q2a. The turbojet engine can operate when provided with air flow in the Mach number range, 0.60 to 0.80. You are asked to analyse a condition where the aircraft is flying at 472 m/s at an altitude of 14,000 m. For all parts of the question, you can assume that the flow path of air through the engine has a circular cross section. (a) normal shock 472 m/s A B (b) intake engine altitude: 14,000 m D exhaust nozzle→ exit to atmosphere 472 m/s 50 m/s B diameter: DE = 0.30 m EX diameter: DF = 0.66 m Figure Q2: Propulsion system for a supersonic aircraft. F a) When the aircraft is at an altitude of 14,000 m, use the International Standard Atmosphere in the Module Data Book to state the local air pressure and tempera- ture. Thus show that the aircraft speed of…arrow_forwardgiven below: A rectangular wing with wing twist yields the spanwise circulation distribution kbV1 roy) = kbv. (2) where k is a constant, b is the span length and V. is the free-stream velocity. The wing has an aspect ratio of 4. For all wing sections, the lift curve slope (ag) is 2 and the zero-lift angle of attack (a=0) is 0. a. Derive expressions for the downwash (w) and induced angle of attack a distributions along the span. b. Derive an expression for the induced drag coefficient. c. Calculate the span efficiency factor. d. Calculate the value of k if the wing has a washout and the difference between the geometric angles of attack of the root (y = 0) and the tip (y = tb/2) is: a(y = 0) a(y = ±b/2) = /18 Hint: Use the coordinate transformation y = cos (0)arrow_forward۳/۱ العنوان O не شكا +91x PU + 96852 A heavy car plunges into a lake during an accident and lands at the bottom of the lake on its wheels as shown in figure. The door is 1.2 m high and I m wide, and the top edge of Deine the hadrostatic force on the Plot the displacement diagram for a cam with roller follower of diameter 10 mm. The required motion is as follows; 1- Rising 60 mm in 135° with uniform acceleration and retardation motion. 2- Dwell 90° 3- Falling 60 mm for 135° with Uniform acceleration-retardation motion. Then design the cam profile to give the above displacement diagram if the minimum circle diameter of the cam is 50 mm. = -20125 750 x2.01arrow_forward

- Plot the displacement diagram for a cam with roller follower of diameter 10 mm. The required motion is as follows; 1- Rising 60 mm in 135° with uniform acceleration and retardation motion. 2- Dwell 90° 3- Falling 60 mm for 135° with Uniform acceleration-retardation motion. Then design the cam profile to give the above displacement diagram if the minimum circle diameter of the cam is 50 mm.arrow_forwardQ1/ A vertical, circular gate with water on one side as shown. Determine the total resultant force acting on the gate and the location of the center of pressure, use water specific weight 9.81 kN/m³ 1 m 4 marrow_forwardI need handwritten solution with sketches for eacharrow_forward

- Given answers to be: i) 14.65 kN; 6.16 kN; 8.46 kN ii) 8.63 kN; 9.88 kN iii) Bearing 6315 for B1 & B2, or Bearing 6215 for B1arrow_forward(b) A steel 'hot rolled structural hollow section' column of length 5.75 m, has the cross-section shown in Figure Q.5(b) and supports a load of 750 kN. During service, it is subjected to axial compression loading where one end of the column is effectively restrained in position and direction (fixed) and the other is effectively held in position but not in direction (pinned). i) Given that the steel has a design strength of 275 MN/m², determine the load factor for the structural member based upon the BS5950 design approach using Datasheet Q.5(b). [11] ii) Determine the axial load that can be supported by the column using the Rankine-Gordon formula, given that the yield strength of the material is 280 MN/m² and the constant *a* is 1/30000. [6] 300 600 2-300 mm wide x 5 mm thick plates. Figure Q.5(b) L=5.75m Pinned Fixedarrow_forwardHelp ارجو مساعدتي في حل هذا السؤالarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Precision Machining Technology (MindTap Course Li...Mechanical EngineeringISBN:9781285444543Author:Peter J. Hoffman, Eric S. Hopewell, Brian JanesPublisher:Cengage Learning

Precision Machining Technology (MindTap Course Li...Mechanical EngineeringISBN:9781285444543Author:Peter J. Hoffman, Eric S. Hopewell, Brian JanesPublisher:Cengage Learning

Precision Machining Technology (MindTap Course Li...

Mechanical Engineering

ISBN:9781285444543

Author:Peter J. Hoffman, Eric S. Hopewell, Brian Janes

Publisher:Cengage Learning

Stresses Due to Fluctuating Loads Introduction - Design Against Fluctuating Loads - Machine Design 1; Author: Ekeeda;https://www.youtube.com/watch?v=3FBmQXfP_eE;License: Standard Youtube License