Traffic and Highway Engineering - With Mindtap

5th Edition

ISBN: 9781305360990

Author: Garber

Publisher: CENGAGE L

expand_more

expand_more

format_list_bulleted

Textbook Question

Chapter 18, Problem 5P

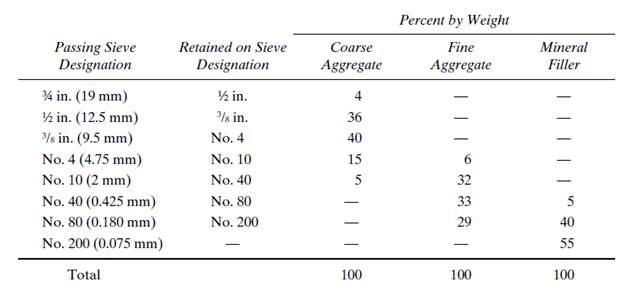

Given the specifications for an asphaltic concrete mixture and the results of a sieve analysis, determine the proportion of different aggregates to obtain the required gradation.

Coarse aggregates: 60%

Fine aggregates: 35%

Filler: 5%

Expert Solution & Answer

Want to see the full answer?

Check out a sample textbook solution

Students have asked these similar questions

8-51. Determine the horizontal displacement at C. Take

E = 29(10³) ksi, I = 150 in for each member. Use the method

of virtual work.

8ft

10 ft

B

5. Problem 8-46 on Page 374.

8-46. The L-shaped frame is made from two fixed-connected

segments. Determine the vertical displacement of the end C.

Use the method of virtual work. El is constant.

-9 ft-

2 k/ft

12 ft

HOMEWORK (1) For the plan and section of the wall shown below, calculate the

following: -

1. the length of footing excavation

2, the length of bricks work under D.P.C for each step

by using:

a) Centre line method

b) Long wall-short wall method

عرف الحق

Im

D.P.C

1.00 m

Section

0.24 m

0.36 m

0.48 m

15 m

r

N

8 m

5 m

Plan

F

Chapter 18 Solutions

Traffic and Highway Engineering - With Mindtap

Ch. 18 - Prob. 1PCh. 18 - Prob. 2PCh. 18 - Prob. 3PCh. 18 - Prob. 4PCh. 18 - Given the specifications for an asphaltic concrete...Ch. 18 - Given the particle size distributions of two...Ch. 18 - Given the particle size distributions of two...Ch. 18 - Given four different types of aggregates to be...Ch. 18 - Prob. 9PCh. 18 - Prob. 10P

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, civil-engineering and related others by exploring similar questions and additional content below.Similar questions

- following: 1. the length of footing excavation 2. the length of bricks work under D.P.C for each step by using: a) Centre line method b) Long wall-short wall method D.P.C 1.00 m 0.24 m 0.36 m y0.48 m 15 m Section. N A k W 8 m 5 m زف الحو 不 Z Plan ate the Larrow_forwardPage 3 3.5) Using the Method of Components, determine the magnitude, the direction, and the sense of the resultant for the coplanar concurrent force system shown below. Y 76 lbs 10 kips 4 3 0 Y 12 kips 5 12 > x 60 lbsarrow_forwardREINFORCED CONCRETE DESIGNFLEXURAL ANALYSIS OF BEAMS (CRACKED SECTION)Solution must be completeUse ballpen/inkpenAnswer in two decimal placesBox your final answerarrow_forward

- A vertical parabolic curve has a back tangent of -5% and a forward tangent of +3% intersecting at station 1 + 240 at an elevation of 100m. If the stationing of PC is at 1 + 120, Evaluate the elevation at the third quarter point.arrow_forwardREINFORCED CONCRETE DESIGNFLEXURAL ANALYSIS OF BEAMS (CRACKED SECTION)Solution must be completeUse ballpen/inkpenAnswer in two decimal placesBox your final answerarrow_forwardWhat is the volume of the earth's mantle in cubic kilometers? (tute problem 4d) Note: enter the number without units. For large (or small) numbers, use E notation, e.g. three million is equivalent to 3*10^6 which is 3E6 in E notation.arrow_forward

- H.W: From an in-out survey conducted for a parking area consisting of 40 bays, the initial count was found to be 20 vehicles. Table gives the result of the survey. The number of vehicles coming in and out of the parking lot for a time interval of 5 minutes is as shown in the table below. Find the accumulation, total parking load, average occupancy and efficiency of the parking lot. Table: In-out survey data Time (minutes) In Out 5 3 2 10 6 2 15 3 1 20 6 7 25 6 4 30 8 6arrow_forwardcan you show me step for step? Autocad has me irritated.arrow_forwardmummins) Is there any risk from a contaminant if 150 out of 3800 people exposed to the groundwater contaminant develop cancer and 125 out of 5000 people not exposed to the contamination also develop cancer? Why or why not? Use at least two methods to support your answer.arrow_forward

- A spare buoy is a buoyant rod weighted to float and protrude vertically, as shown in thefigure below. Suppose that the buoy is made of maple wood ( specific gravity s = 0.6), has arectangular cross section ( 2.54cm by 2.54cm ), a length of 3.7 m , and is floating in seawater( specific gravity s =1.025 ). What weight of steel should be added to the bottom end of thebuoy so that h=0.45 cm? ( The specific gravity of steel s = 7.85 )arrow_forward8-42. Determine the displacement at point D. Use the principle of virtual work. El is constant. 60 kN 2m- 2 m B 30 kN/m 3 marrow_forwardTwo monitoring wells are spaced 500 m apart along the direction of groundwater flow in a confined aquifer 30.0 m thick. The difference in water level in the wells is 2.5 m. The hydraulic conductivity is 40 m/d. a) Sketch the aquifer and wells and label distances and direction of groundwater flow. b) If the real velocity of the groundwater is 0.6 m/d, what is the porosity? c) If it takes 10 years for a petroleum hydrocarbon plume to appear in the second well, what was the retardation factor?arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Traffic and Highway EngineeringCivil EngineeringISBN:9781305156241Author:Garber, Nicholas J.Publisher:Cengage Learning

Traffic and Highway EngineeringCivil EngineeringISBN:9781305156241Author:Garber, Nicholas J.Publisher:Cengage Learning Fundamentals of Geotechnical Engineering (MindTap...Civil EngineeringISBN:9781305635180Author:Braja M. Das, Nagaratnam SivakuganPublisher:Cengage Learning

Fundamentals of Geotechnical Engineering (MindTap...Civil EngineeringISBN:9781305635180Author:Braja M. Das, Nagaratnam SivakuganPublisher:Cengage Learning Construction Materials, Methods and Techniques (M...Civil EngineeringISBN:9781305086272Author:William P. Spence, Eva KultermannPublisher:Cengage Learning

Construction Materials, Methods and Techniques (M...Civil EngineeringISBN:9781305086272Author:William P. Spence, Eva KultermannPublisher:Cengage Learning Materials Science And Engineering PropertiesCivil EngineeringISBN:9781111988609Author:Charles GilmorePublisher:Cengage Learning

Materials Science And Engineering PropertiesCivil EngineeringISBN:9781111988609Author:Charles GilmorePublisher:Cengage Learning Fundamentals Of Construction EstimatingCivil EngineeringISBN:9781337399395Author:Pratt, David J.Publisher:Cengage,

Fundamentals Of Construction EstimatingCivil EngineeringISBN:9781337399395Author:Pratt, David J.Publisher:Cengage, Solid Waste EngineeringCivil EngineeringISBN:9781305635203Author:Worrell, William A.Publisher:Cengage Learning,

Solid Waste EngineeringCivil EngineeringISBN:9781305635203Author:Worrell, William A.Publisher:Cengage Learning,

Traffic and Highway Engineering

Civil Engineering

ISBN:9781305156241

Author:Garber, Nicholas J.

Publisher:Cengage Learning

Fundamentals of Geotechnical Engineering (MindTap...

Civil Engineering

ISBN:9781305635180

Author:Braja M. Das, Nagaratnam Sivakugan

Publisher:Cengage Learning

Construction Materials, Methods and Techniques (M...

Civil Engineering

ISBN:9781305086272

Author:William P. Spence, Eva Kultermann

Publisher:Cengage Learning

Materials Science And Engineering Properties

Civil Engineering

ISBN:9781111988609

Author:Charles Gilmore

Publisher:Cengage Learning

Fundamentals Of Construction Estimating

Civil Engineering

ISBN:9781337399395

Author:Pratt, David J.

Publisher:Cengage,

Solid Waste Engineering

Civil Engineering

ISBN:9781305635203

Author:Worrell, William A.

Publisher:Cengage Learning,

Aggregates: Properties; Author: nptelhrd;https://www.youtube.com/watch?v=49yGZYeokKM;License: Standard YouTube License, CC-BY