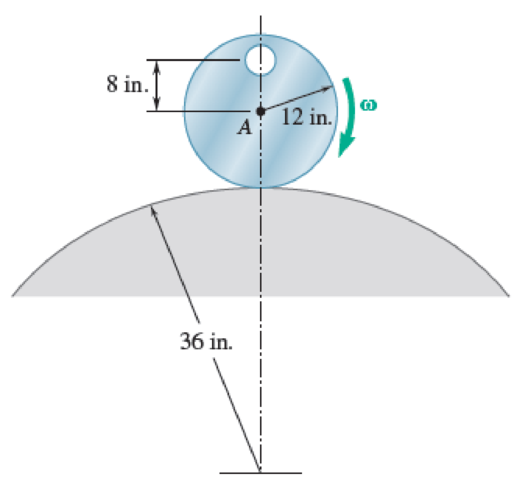

A cylinder with a circular hole is rolling without slipping on a fixed curved surface as shown. The cylinder would have a weight of 16 lb without the hole, but with the hole it has a weight of 15 lb. Knowing that at the instant shown the disk has an angular velocity of 5 rad/s clockwise, determine (a) the angular acceleration of the disk, (b) the components of the reaction force between the cylinder and the ground at this instant.

Fig. P16.161

(a)

The angular acceleration of the disk.

Answer to Problem 16.161RP

The angular acceleration of the disk is

Explanation of Solution

Given information:

The weight of the cylinder without hole is

The weight of the cylinder with hole is

The angular velocity of the disk is

Calculation:

Consider the acceleration due to gravity as

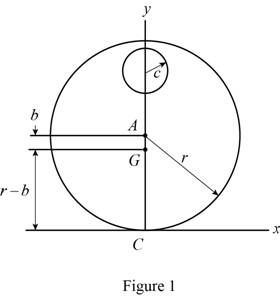

Consider that the mass center of the cylinder is G and it lies at a distance b from center A, and C is the contact point between cylinder and the curved surface is the origin of the coordinate system.

Consider that the radius of cylinder is r and the radius of the curved surface is R.

Sketch the geometry of the cylinder as shown in Figure 1.

Refer to Figure 1.

Calculate the position vector

The position vector of P with respect to C.

The position vector of G with respect to C.

The position vector of A with respect to C.

The cylinder rolls without slipping on a fixed curved surface hence, the horizontal component of acceleration of point C is

Calculate the acceleration of point C

Substitute 0 for

The acceleration of the disk at A is

Calculate the acceleration of point A

Substitute

Calculate the acceleration of point P

Here,

Substitute

Calculate the acceleration of point G

Substitute

Calculate the acceleration of point A

Substitute

Subtract Equation (2) from Equation (1) as shown below.

Substitute

Calculate the velocity of point A

Calculate the vertical component of acceleration of point A

Substitute

Calculate the acceleration of point G

Substitute

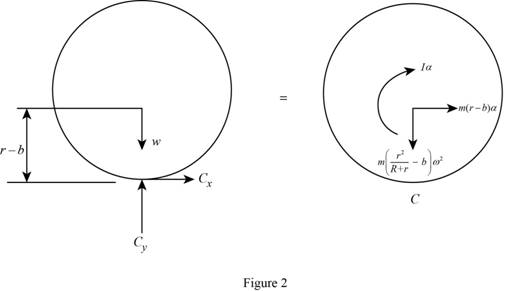

Calculate the effective force at the mass center

Sketch the Free Body Diagram of the cylinder as shown in Figure 2.

Refer to Figure 2.

Apply the Equilibrium of moment about C as shown below.

Hence, the angular acceleration of the disk is

(b)

The components of the reaction force between the cylinder and the ground.

Answer to Problem 16.161RP

The component of the reaction along x direction is

The component of the reaction along y direction is

Explanation of Solution

Given information:

The weight of the cylinder without hole is

The weight of the cylinder with hole is

The angular velocity of the disk is

Calculation:

Refer to part (a).

The angular acceleration of the disk is

Refer to Figure 2.

Apply the Equilibrium of force along x direction as shown below.

Substitute 0 for

Hence, the component of the reaction along x direction is

Apply the Equilibrium of force along y direction as shown below.

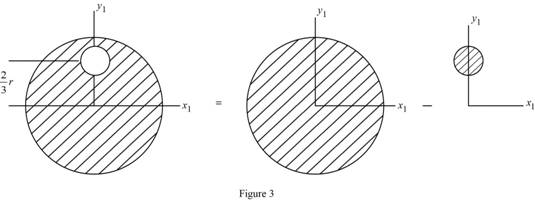

Sketch the cylinder with hole as shown in Figure 3.

Refer to Figure 3.

Calculate the area of solid cylinder

Calculate the center of gravity of solid cylinder in vertical direction

Calculate the area of hole

Calculate the center of gravity of hole in vertical direction

Calculate the distance

Substitute

Calculate the component of the reaction along y direction as shown below.

Substitute

Therefore, the component of the reaction along y direction is

Want to see more full solutions like this?

Chapter 16 Solutions

VECTOR MECH...,STAT.+DYNA.(LL)-W/ACCESS

Additional Engineering Textbook Solutions

Vector Mechanics For Engineers

Mechanics of Materials (10th Edition)

Database Concepts (8th Edition)

Electric Circuits. (11th Edition)

Concepts Of Programming Languages

Thermodynamics: An Engineering Approach

- Solve this problem and show all of the workarrow_forwardSolve this problem and show all of the workarrow_forwardPart A The man pulls on the rope with a force of F = 30 N as shown in (Figure 1). Figure 1.5 m 3 m. 4m 10.5 m 1 of 1 Determine the position vector from O to A. Express the x, y, and z components of the position vector in meters to three significant figures separated by commas. ΜΕ ΑΣΦ vec (TOA). (TOA)y. (TOA)== Submit Request Answer Part B m Determine the position vector from O to B. Express the x, y, and z components of the position vector in meters to three significant figures separated by commas. ΜΕ ΑΣΦ ↓↑ vec (TOB)x, (TOB)y, (TOB) = Submit Request Answer Part C Complete previous part(s) Provide Feedback ? marrow_forward

- 4 Part A The tool is used to shut off gas valves that are difficult to access (Figure 1). Figure 0.25 m 30 0,4 m < 1 of 1 If the force F= {-60i+40j+15k} N is applied to the handle, determine the component of the moment created about the z axis of the valve. Express your answer with the appropriate units. Mz = Value Submit Request Answer Provide Feedback | ? Unitsarrow_forward3. A steam power plant has an average monthly net power delivery of 740 MW over the course of a year. This power delivery is accomplished by burning coal in the boiler. The coal has a heating value of 9150 Btu/lbm. The cost of the coal is $14.20/ton. The overall thermal efficiency of the plant is, nth Wnet Qboiler 0.26 = 26% Determine the annual cost of the coal required to deliver the given average monthly power.arrow_forwardThe cable exerts a force of P = 4 kN at the end of the 8-m-long crane boom. A P 8 m B -x- I'm En ▾ Part A If 0 = 30°, determine the placement x of the boom at B so that this force creates a maximum moment about point O. Express your answer to three significant figures and include the appropriate units. x = 9.81 m Submit Previous Answers ✓ Correct ▾ Part B What is this moment? Express your answer to three significant figures and include the appropriate units. Assume the positive direction is counterclockwise. (Mo) max 43.7 = E ? N Submit Previous Answers Request Answer X Incorrect; Try Again; 28 attempts remaining Enter your answer with a different unit type. Review a list of acceptable units.arrow_forward

- Find highest and lowest temperature.arrow_forwardExplained step by step.arrow_forwardThe bevel gear shown in is subjected to the force F which is caused from contact with another gear. Part A F (201+8j 15k) N 40 mm Determine the moment of this force about the y axis of the gear shaft. Express your answer with the appropriate units. My = Value Submit Request Answer ? Units 30 mmarrow_forward

- Consider the beam in. Part A 1.5 ft 200 lb 200lb 2 ft 30° 1.25 ft 30° If F 90 lb, determine the resultant couple moment. = Express your answer in pound-feet to three significant figures. Assume the positive direction is counterclockwise. ΑΣΦ vec MR = Submit Request Answer ? lb.ftarrow_forward4. An operating parameter often used by power plant engineers is the heat rate. The heat rate is defined as, HR Qbioler Wnet where Qbioler is the heat transfer rate (Btu/h) to the water in the boiler due to the combustion of a fuel and Wnet is the net power (kW) delivered by the plant. In comparison, the thermal efficiency of the power plant is defined as, nth Wnet Qbioler where the numerator and denominator have the same units. Consider a power plant that is delivering 1000 MW of power while utilizing a heat transfer rate of 3570 MW at the boiler. Determine the heat rate and thermal efficiency of this power plant.arrow_forwardThe shaft shown in the sketch is subjected to tensile torsional and bending loads Determine the principal stresses at the location of stress concentration ✓ D=45MR F=3MM 1000-M 1000N チ d=30mm 500N 150 мм MM- 120 MA-arrow_forward

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY