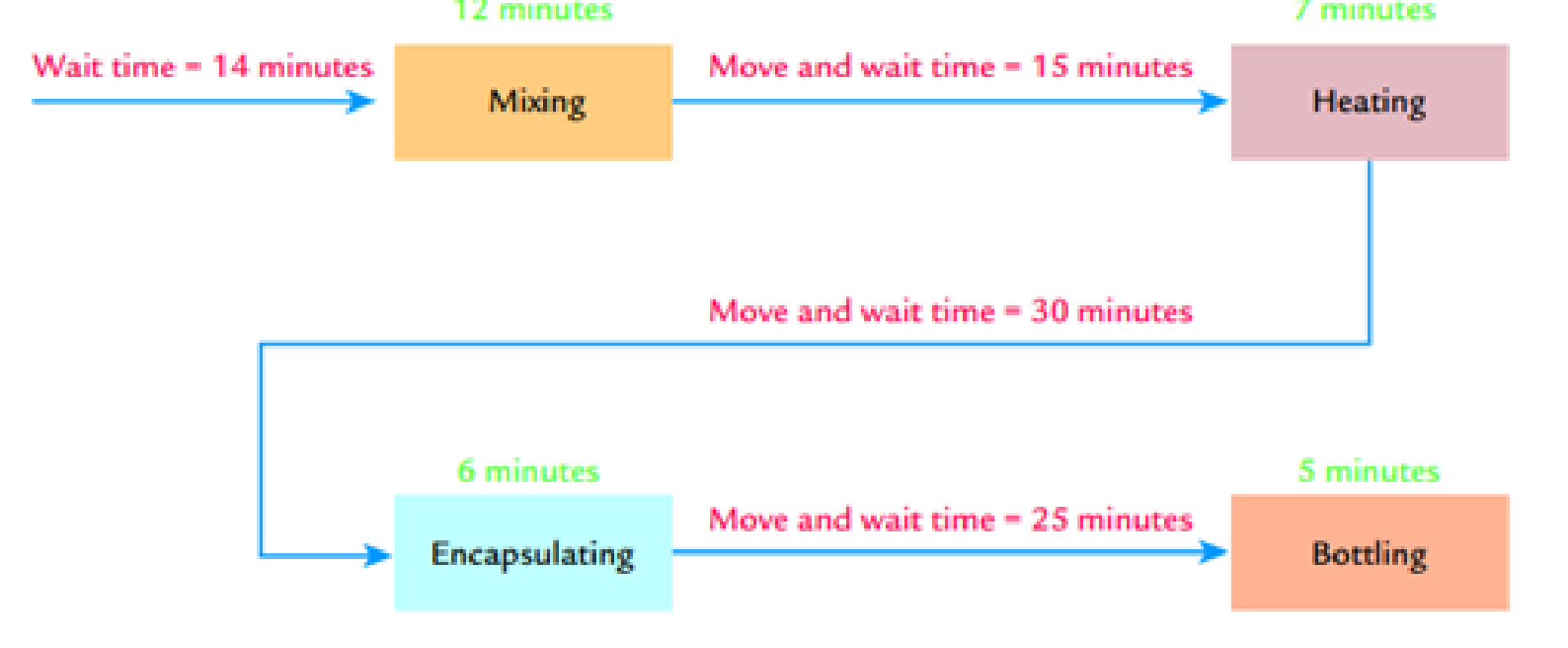

Erba Inc. has the following departmental layout for producing an herbal supplement:

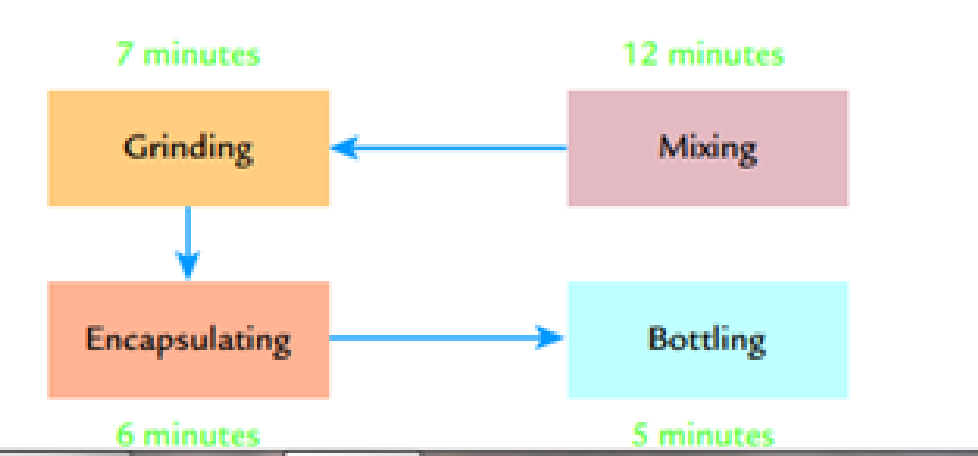

After a detailed study, the head of the plant’s industrial engineering department recommended that the following cellular manufacturing layout replace the current departmental structure:

Required:

- 1. Calculate the time required to produce a batch of 12 bottles using a batch processing departmental structure.

- 2. Calculate the time to process 12 units using cellular manufacturing.

- 3. How much manufacturing time will the cellular manufacturing structure save for a batch of 12 units?

- 4. How many units can the cell produce per hour, assuming the cell is producing on a continuous basis?

- 5. What must happen so that the cell can produce 12 units per hour, assuming the cell produces on a continuous basis?

1.

Compute the time taken to produce 12 units in case of a traditional manufacturing layout.

Answer to Problem 43E

Total time taken is 444 minutes.

Explanation of Solution

Traditional manufacturing layout:

In a traditional manufacturing layout, each process is undertaken within a separate department. In this layout large batches are processed, incurring significant wait time and move time.

Computation of time taken by 12 units:

| Particulars | Minutes |

| Wait time | 14 |

| Add: Time taken in mixing department | 144 |

| Add: Move and wait time between mixing and heating department | 15 |

| Add: Time taken in heating department | 84 |

| Add: Move and wait time between heating and encapsulating department | 30 |

| Add: Time taken in encapsulating department | 72 |

| Add: Move and wait time between encapsulating and bottling department | 25 |

| Add: Time taken in bottling department | 60 |

| Total time | 444 |

Table (1)

Therefore, total time taken is 444 minutes.

2.

Compute the time taken to produce 12 units in case of a cellular manufacturing layout.

Answer to Problem 43E

Total time taken to produce 12 units in cellular manufacturing is 162 minutes.

Explanation of Solution

Computation of time taken by 12 units:

| Particulars | Minutes |

|

Time taken by first unit | 30 |

|

Time taken by second unit | 42 |

|

Time taken by twelfth unit. | 162 |

| Total time | 162 |

Table (2)

Therefore, total time taken to produce 12 units in cellular manufacturing is 162 minutes.

3.

Compute the time saved in cellular manufacturing structure for a batch of 12 units.

Answer to Problem 43E

Time saved in cellular manufacturing structure for a batch of 12 units is 282 minutes.

Explanation of Solution

Computation of time saved in cellular manufacturing:

| Particulars | Minutes |

| Total time taken in traditional/batch processing | 444 |

| Total time taken in cellular processing | 162 |

| Time saved | 282 |

Table (3)

Therefore, time saved in cellular manufacturing structure for a batch of 12 units is 282 minutes.

4.

Compute the production rate in case of continuous operating.

Answer to Problem 43E

Production rate is 12 minutes per unit or 5 units per hour.

Explanation of Solution

There is a total of 12 minutes of waiting for each unit. In case, cell operates continuously and steadily, one unit would be produced after every 12 minutes. Therefore, it would take 144 minutes

Therefore, production rate is 12 minutes per unit or 5 units

5.

Explain the changes to be made so that the cell can produce 12 units per hour in case, cell produces on a continuous basis.

Answer to Problem 43E

Time taken by bottleneck activity should be 5 minutes.

Explanation of Solution

Computation of revised time taken by bottleneck activity:

Substitute 60 for minutes in an hour and 12 for the number of units required to be produced in the above formula.

The incremental time taken by each unit should be 5 minutes, in order to produce 12 units per hour on an incremental basis. For this, maximum time taken by any process should be 5 minutes.

Therefore, to produce 12 units per hour, time taken by bottleneck activity should be 5 minutes.

Want to see more full solutions like this?

Chapter 13 Solutions

Bundle: Managerial Accounting: The Cornerstone of Business Decision-Making, Loose-Leaf Version, 7th + CengageNOWv2, 1 term (6 months) Printed Access Card

- Hii expert please given correct answer general accountingarrow_forwardMarkowis Corp has collected the following data concerning its maintenance costs for the pest 6 months units produced Total cost July 18,015 36,036 august 37,032 40,048 September 36,036 55,055 October 22,022 38,038 November 40,040 74,575 December 38,038 62,062 Compute the variable coot per unit using the high-low method. (Round variable cost per mile to 2 decimal places e.g. 1.25) Compute the fixed cost elements using the high-low method.arrow_forwardUse the following data to determine the total dollar amount of assets to be classified as current assets. Marigold Corp. Balance Sheet December 31, 2025 Cash and cash equivalents Accounts receivable Inventory $67000 Accounts payable $126000 86500 Salaries and wages payable 11100 149000 Bonds payable 161500 Prepaid insurance 83000 Total liabilities 298600 Stock investments (long-term) 193000 Land 199500 Buildings $226000 Common stock 309400 Less: Accumulated depreciation (53500) 172500 Retained earnings 475500 Trademarks 133000 Total stockholders' equity 784900 Total assets $1083500 Total liabilities and stockholders' equity $1083500 ○ $269100 $385500 ○ $236500 ○ $578500arrow_forward

- Should the machine be replaced?arrow_forwardUsing the following balance sheet and income statement data, what is the total amount of working capital? Current assets $39700 Net income $52100 Current liabilities 19800 Stockholders' equity 96700 Average assets 198400 Total liabilities 52100 Total assets 148800 Average common shares outstanding was 18600. ○ $9900 ○ $39700 ○ $19900 ○ $12400arrow_forwardSuppose that Old Navy has assets of $4265000, common stock of $1018000, and retained earnings of $659000. What are the creditors' claims on their assets? ○ $2588000 ○ $3906000 ○ $1677000 ○ $4624000arrow_forward

- Brody Corp. uses a process costing system. Beginning inventory for January consisted of 1,400 units that were 46% completed. 10,300 units were started during January. On January 31, the inventory consisted of 550 units that were 77% completed. How many units were completed during the period?arrow_forwardCurrent Attempt in Progress Whispering Winds Corp. has five plants nationwide that cost $275 million. The current fair value of the plants is $460 million. The plants will be reported as assets at $735 million. O $460 million. $275 million. O $185 million.arrow_forwardBased on the following data, what is the amount of current assets? Accounts payable $62000 Accounts receivable 116000 Cash 66000 Intangible assets 116000 Inventory 142000 Long-term investments 161500 Long-term liabilities 199000 Short-term investments 85000 Notes payable 56500 Property, plant, and equipment 132000 Prepaid insurance 2500arrow_forward

- Calculate the firm's estimated free cash flowarrow_forward#10. Recall that Unique Industries had estimated $1,055,000 of MOH for the year and 64,500 DL hours, resulting in a predetermined MOH rate of $14/DL hour. By the end of the year, the company had actually incurred $925,000 of MOH costs and used a total of 64,000 DL hours on jobs. By how much had Unique Industries overallocated or underallocated MOH for the year? Part 1 Compute the underallocated or overallocated overhead. (Use parentheses or a minus sign for overallocated overhead.) Actual MOH – Allocated MOH = (Over) Under Allocated - =arrow_forwardSterling Equipment Ltd. purchased machinery for $80,000 with a salvage value of $5,000 and a 6-year useful life. The company initially used the straight-line method, but after two years, switched to the double-declining balance method. What is the depreciation expense for Year 3?arrow_forward

Managerial Accounting: The Cornerstone of Busines...AccountingISBN:9781337115773Author:Maryanne M. Mowen, Don R. Hansen, Dan L. HeitgerPublisher:Cengage Learning

Managerial Accounting: The Cornerstone of Busines...AccountingISBN:9781337115773Author:Maryanne M. Mowen, Don R. Hansen, Dan L. HeitgerPublisher:Cengage Learning Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage Learning

Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage Learning Essentials of Business Analytics (MindTap Course ...StatisticsISBN:9781305627734Author:Jeffrey D. Camm, James J. Cochran, Michael J. Fry, Jeffrey W. Ohlmann, David R. AndersonPublisher:Cengage Learning

Essentials of Business Analytics (MindTap Course ...StatisticsISBN:9781305627734Author:Jeffrey D. Camm, James J. Cochran, Michael J. Fry, Jeffrey W. Ohlmann, David R. AndersonPublisher:Cengage Learning