Interpretation:

The amount of Aluminum required to be added and the liquid mixture cooled

diagram needs to be determined by referring to the given phase.

Concept introduction:

The aluminum alloy consists of aluminum as the parent material or the main constituent of the alloy. Aluminum alloy develops a white surface which acts as a protective layer of aluminum oxide.

Aluminum alloy has its major applications in the field of Aerospace industry as they are lighter, less flammable and have more strength.

Phase diagram is used to represent the

Answer to Problem 12.17P

The amount of aluminum to be added is calculated as

Explanation of Solution

Given Information:

Amount of aluminum

Weight percent of Cu-Al alloy

Calculation:

The composition of the Cu-Al alloy is Cu-

To calculate the temperature of the alloy, following expression is used,

Where, the alloy temperature=

The upper boundary temperature=

The lower boundary temperature=

Now, substituting the values as

Fig.

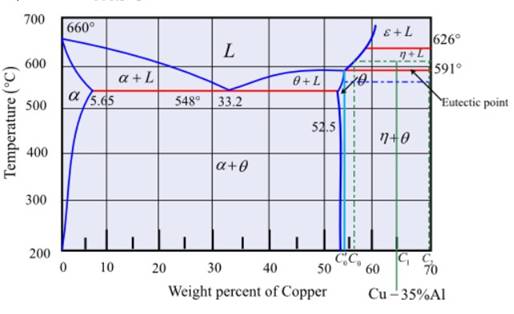

In the above-mentioned phase diagram, the Cu-

To calculate the weight percent of the alloy at temperature

Where,

Substituting the values as

To calculate the weight percentage of the mentioned alloy at the eutectic temperature

Where

Substituting the values as

Now, to calculate the amount of the aluminum to be added more, the following formula is used:

Where

Substituting the values as,

Putting the values,

To calculate the temperature change,

Where the values substituted are

Thus, based on the phase diagram of Cu-

Want to see more full solutions like this?

Chapter 12 Solutions

Essentials Of Materials Science And Engineering

- (Read Image) (Answer: ω = 1.10 rad/sec CW)arrow_forwardI need help writing pseudocode for this function. The following pseudocode statement calls a function named half, which returns a value that is half that of the argument. (Assume both the result and number variables are Real.) Set result = half(number)arrow_forwardNeed help converting my pseudocode to python, AND have a flowchart showing everything!The code:Main Module Call InputModuleEnd Main Module Module InputModule // This module gets input from the user Declare Principal, AnnualRate, Years as Float Output "Enter the Principal amount (P): " Input Principal Output "Enter the Annual Interest Rate (in percentage, e.g., 5 for 5%): " Input AnnualRate Output "Enter the number of Years to repay the loan: " Input Years Call DisplayPayment(Principal, AnnualRate, Years)End Module Module DisplayPayment(Principal, AnnualRate, Years) // This module calculates and displays the monthly payment Declare R, N as Float Declare MonthlyPayment as Float Declare PowerFactor as Float // second local variable // Calculate monthly interest rate R and number of months N Set R = (AnnualRate / 100) / 12 Set N = Years * 12 // Calculate PowerFactor = (1 + R)^N Set PowerFactor = (1 + R) ^ N // Calculate…arrow_forward

- What is the configuration of the control loop if steam must be shut down in case of a problem? (I found this question on the internet and was wondering what the answer is) A.Valve is fail open, PIC is direct-acting, TIC is reverse acting, and controller algorithm is feed-forwarding.B. Valve is fail open, PIC is reverse-acting, TIC is direct acting, and controller algorithm is cascade.C. Valve is fail closed, PIC is direct-acting, TIC is reverse acting, and controller algorithm is feed-forward.D. Valve is fail closed, PIC is reverse-acting, TIC is reverse acting, and controller algorithm is cascade.arrow_forwardWhat is the procedure to replace the input bellows?(I found this question on the internet and was wondering what the correct answer is out of interest) Remove tubing, old bellows and flapper assembly, install new bellows, connect tubing, install flapper assembly, then calibrate the positioner.Remove tubing, old bellows and cam, install new bellows, connect tubing, install cam, then calibrate the positioner.C. Remove tubing and old bellows, align the quadrant beam, install new bellows and connect tubing, then calibrate the positioner.D. Remove tubing and old bellows, install new bellows and connect tubing, align the quadrant beam, then calibrate the positioner.arrow_forwardGiven the following information: (I found this question on the internet and was wondering what the correct answer is) Firing rate demand = 20% Fuel air ratio = 2:1 Fuel flow = 20% Minimum air flow setting = 5% What is the set point for the air flow controller? 5%B. 10%C. 25%D. 40%arrow_forward

- Please answer the questions in the picture. Thank you for your help. For part B use the Second Picture.arrow_forward. Where is a dew point analyzer installed to measure instrument air?(I found this question on the internet and am wondering what the correct answer is) A. AB. BC. CD. Darrow_forwardThe piston at the bottom of the stroke is 0% open. Which adjustment will change the zero setting to 5% open? ( I found this sample question on the internet and was wondering what the correct answer is out of interest) A.Slide component 2 towards the pivotB. Slide component 2 away from the pivot.C. Increase spring tension using adjustment 1.D. Decrease spring tension using adjustment 1.arrow_forward

- Whats wrong with my pseudocode? Where did I make an error?Code: Module main() Declare Real mileage Call getMileage() Display “You’ve drive a total of “, mileage, “ miles End Module Module getMilage() Display “Enter your mileage: “ Input mileage End Modulearrow_forward(read image) (Answer: vA = 4.57 ft/sec)arrow_forward(read image) (answer: αAB = 14.38 rad/s2 CW)arrow_forward

MATLAB: An Introduction with ApplicationsEngineeringISBN:9781119256830Author:Amos GilatPublisher:John Wiley & Sons Inc

MATLAB: An Introduction with ApplicationsEngineeringISBN:9781119256830Author:Amos GilatPublisher:John Wiley & Sons Inc Essentials Of Materials Science And EngineeringEngineeringISBN:9781337385497Author:WRIGHT, Wendelin J.Publisher:Cengage,

Essentials Of Materials Science And EngineeringEngineeringISBN:9781337385497Author:WRIGHT, Wendelin J.Publisher:Cengage, Industrial Motor ControlEngineeringISBN:9781133691808Author:Stephen HermanPublisher:Cengage Learning

Industrial Motor ControlEngineeringISBN:9781133691808Author:Stephen HermanPublisher:Cengage Learning Basics Of Engineering EconomyEngineeringISBN:9780073376356Author:Leland Blank, Anthony TarquinPublisher:MCGRAW-HILL HIGHER EDUCATION

Basics Of Engineering EconomyEngineeringISBN:9780073376356Author:Leland Blank, Anthony TarquinPublisher:MCGRAW-HILL HIGHER EDUCATION Structural Steel Design (6th Edition)EngineeringISBN:9780134589657Author:Jack C. McCormac, Stephen F. CsernakPublisher:PEARSON

Structural Steel Design (6th Edition)EngineeringISBN:9780134589657Author:Jack C. McCormac, Stephen F. CsernakPublisher:PEARSON Fundamentals of Materials Science and Engineering...EngineeringISBN:9781119175483Author:William D. Callister Jr., David G. RethwischPublisher:WILEY

Fundamentals of Materials Science and Engineering...EngineeringISBN:9781119175483Author:William D. Callister Jr., David G. RethwischPublisher:WILEY