Concept explainers

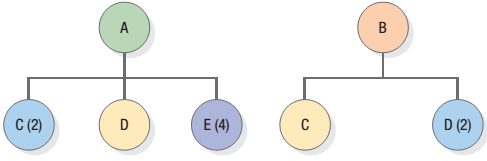

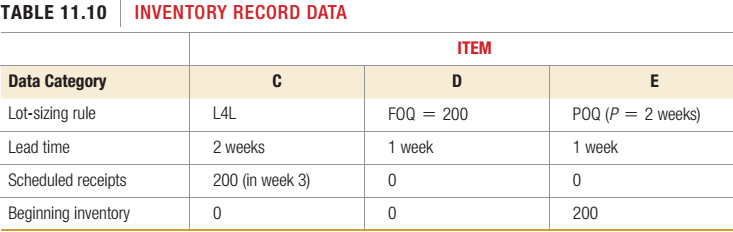

The BOMs for products A & B and data from the inventory records are shown in Figure 11.41. Data from the inventory records are shown in Table 11.10. In the MPS for product A, the MPS start row has 85 units in week 2 and 200 in week 4 and 50 in week 8. In the MPS for product B, the MPS start row has 65 units in week 3 and 50 in week 4 and 50 in week 5 and 75 in week 8.

- Develop the material requirements plan for the next 8 weeks for items C, D, and E. Note any difficulties you observe in the inventory records.

- Can the difficulties noted in part (a) be rectified by expediting any

Scheduled Receipts?

Want to see the full answer?

Check out a sample textbook solution

Chapter 11 Solutions

Operations Management: Processes And Supply Chains (12th Edition) (what's New In Operations Management)

Additional Business Textbook Solutions

Operations Management

Business in Action (8th Edition)

Business in Action

Operations and Supply Chain Management 9th edition

Loose-leaf for Operations Management (The Mcgraw-hill Series in Operations and Decision Sciences)

OPERATIONS MANAGEMENT IN THE SUPPLY CHAIN: DECISIONS & CASES (Mcgraw-hill Series Operations and Decision Sciences)

- One unit of Part C is used in item A and in item B. Currently, we have 10 As, 20 Bs, and 100 Cs in inventory. We want to ship 60 As and 70 Bs. How many additional Cs do we need to purchase?arrow_forwardThe planned order receipt for item A is 200 in week 5 and the lead time is 3 weeks. Which week should the planned order release be?arrow_forwardThe product structure for product X is illustrated below. Level 0 Level 1 4 Level 2 Level 3 Part H B C D H K M N X Z с K B Lead Time (in weeks) 1 1 3 2 3 2 3 3 4 M D N The lead time for manufacturing any number units for an item and the required number of units for the lower level part in the product structure are reported in the following table. For example, each unit of Part X requires 1 units of Part C and, in turn, each unit of Part C requires 2 units of Part H and 2 units of Part K. 2 1 4 2 2 2 4 1 2 Required number of units X Z H K 100 units of product X are to shipped at the end of week 25. There is no inventory on hand. How many units of part N are required for production? 3200 Specify only the number.arrow_forward

- When selecting date units for grouping, users can select multiple units of measure. True Falsearrow_forwardThe master production schedule (MPS) specifies: Select one: None of the mentioned When the finished products are needed All of the mentioned. When the subcomponents are needed Which subcomponents a firm is to produce How many subcomponents are needed. Mit Carrow_forwardAn end item’s demand forecasts for the next 10 weeks are 30, 30, 30, 30, 20, 20, 30, 30, 30, and 30 units. The current onhand inventory is 100 units. The order policy is to produce in lots of 75. The booked customer orders for the item, starting with week 1, are 15, 38, 7, 5, 0, 3, 10, 0, 0, and 0 units. The lead time is 2 weeks.a. Develop an MPS for this end item.b. The marketing department has received five orders for this item in the following sequence:Order 1 is for 20 units to be delivered in period 1Order 2 is for 75 units to be delivered in period 4Order 3 is for 90 units to be delivered in period 6Order 4 is for 75 units to be delivered in period 7Order 5 is for 90 units to be delivered in period 10Assuming that the prospective MPS you developed in part (a) does not change, which orders would you be able to accept based on the available to promise (ATP)?arrow_forward

- A company produces skateboards. Each skateboard (A) consists of one unit of board (B), and two units of sub-assembly of roller-set (C). Roller-sets comprise of 2 components: 2 rollers (D) and one axle (E). The MPS is as follows: Week 1 2 3 4 5 6 7 8 9 10 A D 40 50 60 80 What are the planned order releases for item A? A has an on-hand inventory of 10, safety stock of 0. The lead time is 1 week and the ordering policy is Lot-for-Lot (L4L).arrow_forwardA product (A) consists of a base (B) and a casting (C). The base consists of a plate(P) and three fasteners (F). The lead time, current on-hand inventory and scheduledreceipts are given in the table below. All components are lot for lot. The MasterSchedule requires 100 units of product A be available in week 4 and 150 in week 6. Part Lead time On - Hand inventory Scheduled receipts A 1 20 None B 1 100 50 in Week 1 C 3 30 20 in Week 1, 30 in Week 2 P 2 0 50 in Week 1 F 3 0 30 in Week 1, 40 in Week 3 Required:A. Draw the product structure tree. B. Develop the MRP for Parts A, B, C, P, and F in order to meet the demand. Therows for MRP tables are Gross Requirement (GR), Scheduled Receipt (SR),On-Hand Inventory (OHI), Net Requirement (NR), and Planned Production (PP).arrow_forwardAs the production planner for Xiangling Hu Products, Inc., you have been given a bill of material for a bracket that is made up of a base, 2 springs, and 4 clamps. The base is assembled from 1 clamp and 2housings. Each clamp has 1 handle and 1 casting. Each housing has 2 bearings and 1 shaft. There is no inventory on hand. Your boss at Xiangling Hu Products, Inc., has just provided you with the schedule and lead times for the bracket. The unit is to be prepared in week 12.The lead times for the components are bracket (1 week), base (1 week), spring (1 week), clamp (1 week), housing (3weeks), handle (2weeks), casting (4weeks), bearing (1 week), and shaft (1 week). Part 3 b) In what week do you need to start the castings? The castings need to be started in week enter your response here (enter your response as a whole number).arrow_forward

- As the production planner for Xiangling Hu Products, Inc., you have been given a bill of material for a bracket that is made up of a base, 2 springs, and 4 clamps. The base is assembled from 2 clamps and 1 housing. Each clamp has 1handle and 1 casting. Each housing has 2 bearings and 2 shafts. There is no inventory on hand. c) Compute the net quantities needed if there are 25 of the base and 100 of the clamp in stock. Base: units (enter your response as a whole number). Spring: units Clamp: units Housing: units Handle units Casting: units Bearing: units Shaft: unitsarrow_forwardProduct W requires components A, B, C, D, E and F. A unit of W requires 1 unit of A, 2 units of B and 4 units of C. A requires 2 units of D and 1 unit of E. B requires 2 units of E and 1 unit of F. C requires 3 units of D and 2 units of F. Draw the product structure tree. Determine the quantities of the required components for manufacturing 150 units of W.arrow_forwardsolve all the parts within 30 minutes.arrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,