Concept explainers

Cost Data for Managerial Purposes

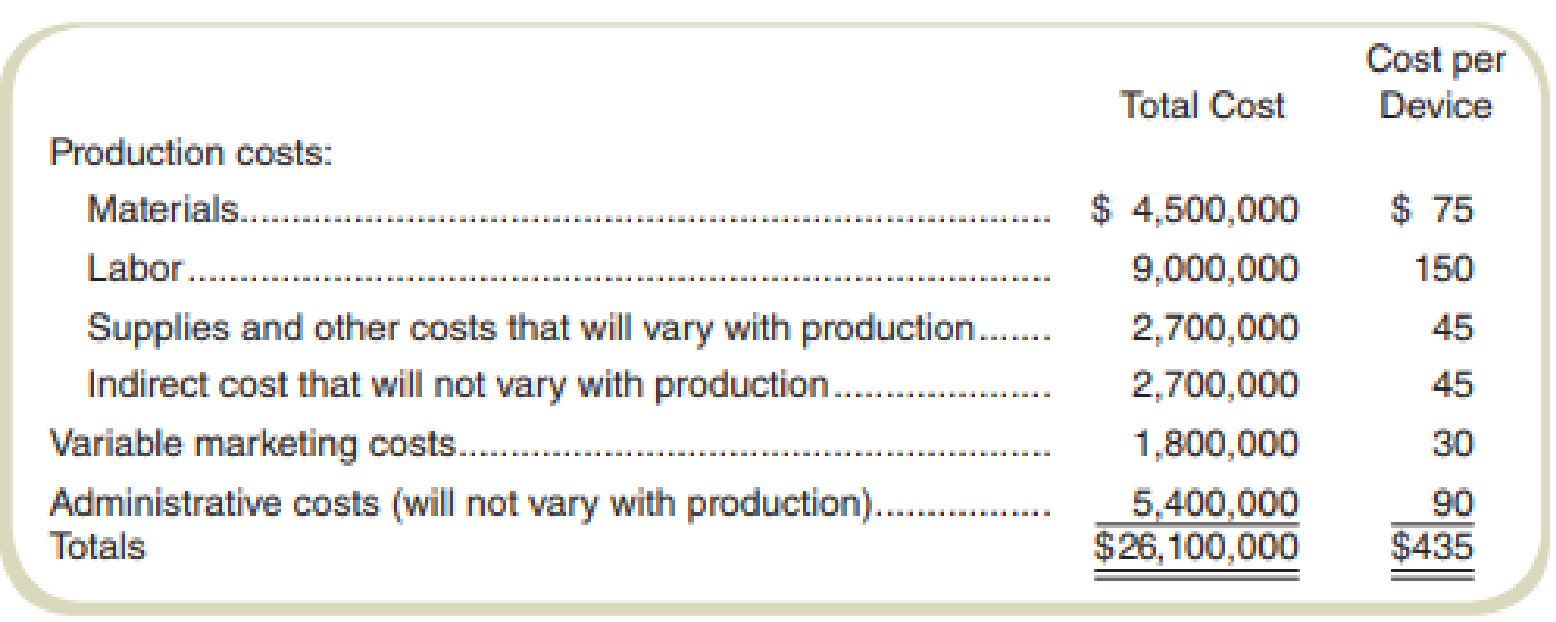

Imperial Devices (ID) has offered to supply the state government with one model of its security screening device at “cost plus 20 percent.” ID operates a manufacturing plant that can produce 66,000 devices per year, but it normally produces 60,000. The costs to produce 60,000 devices follow:

Based on these data, company management expects to receive $522 (= $435 × 120 percent) per monitor for those sold on this contract. After completing 500 monitors, the company sent a bill (invoice) to the government for $261,000 (= 500 monitors × $522 per monitor).

The president of the company received a call from a state auditor, who stated that the per

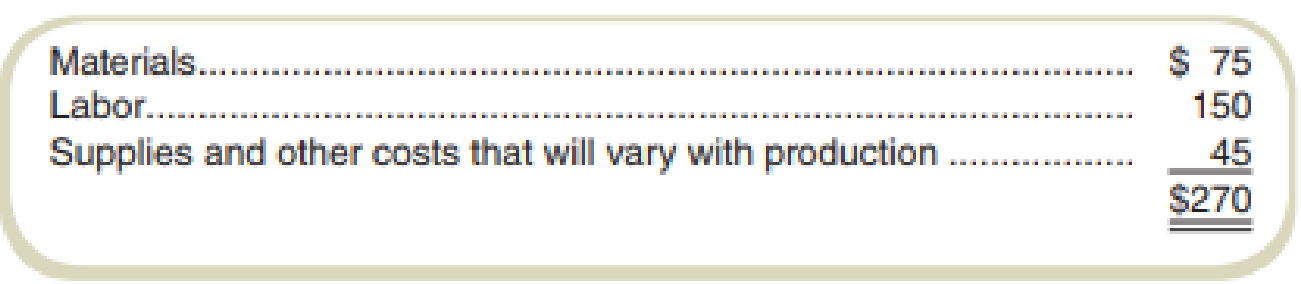

monitor cost should be:

Therefore, the price per monitor should be $324 (= $270 × 120 percent). The state government ignored marketing costs because the contract bypassed the usual selling channels.

Required

What price would you recommend? Why? (Note: You need not limit yourself to the costs selected by the company or by the government auditor.)

Want to see the full answer?

Check out a sample textbook solution

Chapter 1 Solutions

Fundamentals of Cost Accounting

- Principles of Accounting Volume 2AccountingISBN:9781947172609Author:OpenStaxPublisher:OpenStax College

Managerial AccountingAccountingISBN:9781337912020Author:Carl Warren, Ph.d. Cma William B. TaylerPublisher:South-Western College Pub

Managerial AccountingAccountingISBN:9781337912020Author:Carl Warren, Ph.d. Cma William B. TaylerPublisher:South-Western College Pub Managerial Accounting: The Cornerstone of Busines...AccountingISBN:9781337115773Author:Maryanne M. Mowen, Don R. Hansen, Dan L. HeitgerPublisher:Cengage Learning

Managerial Accounting: The Cornerstone of Busines...AccountingISBN:9781337115773Author:Maryanne M. Mowen, Don R. Hansen, Dan L. HeitgerPublisher:Cengage Learning