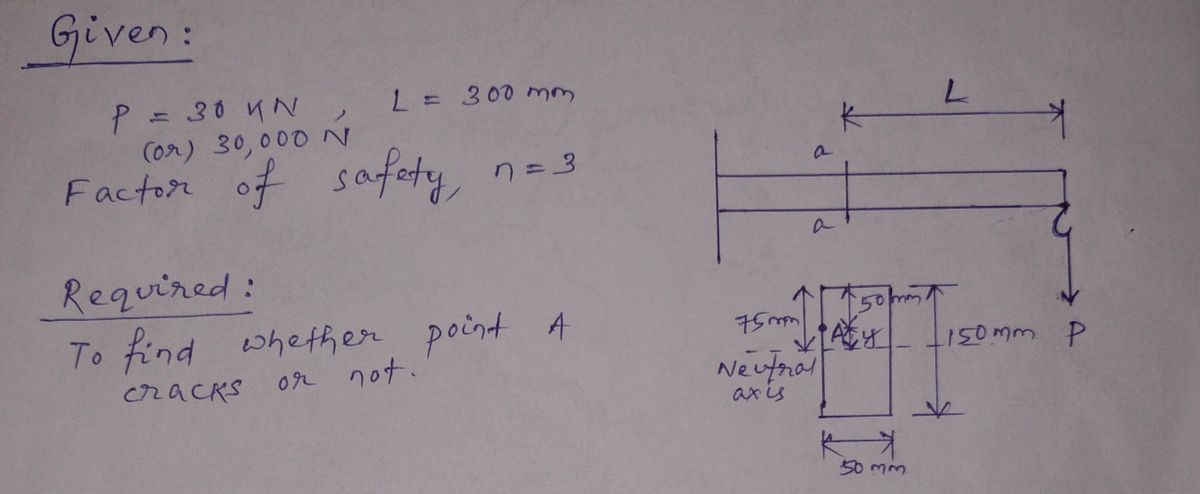

A massless bar has a rectangular cross-section as shown in the figure. The rod is made of Cast Iron Gray ASTM 20. Under the loading conditions as shown in the picture with a factor of safety of n = 3, will point A crack?

A massless bar has a rectangular cross-section as shown in the figure. The rod is made of Cast Iron Gray ASTM 20. Under the loading conditions as shown in the picture with a factor of safety of n = 3, will point A crack?

Elements Of Electromagnetics

7th Edition

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Sadiku, Matthew N. O.

ChapterMA: Math Assessment

Section: Chapter Questions

Problem 1.1MA

Related questions

Question

A massless bar has a rectangular cross-section as shown in the figure. The rod is made of Cast Iron Gray ASTM 20. Under the loading conditions as shown in the picture with a factor of safety of n = 3, will point A crack?

Transcribed Image Text:50 mm

a

IT

A 150 mm

50 mm

Section a-a

300 mm

30 kN

![50 mm

a

a

T

A 150 mm

50 mm

Section a-a

300 mm

Soal Hibbler F9-11

Sebuah batang tanpa massa mempunyai penampang berbentuk balok seperti pada gambar. Batang terbuat dari

Cast Iron Gray ASTM 20. Pada kondisi pembebanan seperti pada gambar dengan angka keamanan n = 3, apakah

pada point A akan mengalami retak ?

Yield Strength (MPa) Ultimate Strength (MPa)

Materials

Moduls of

Density p Elasticity E

(Mg/m³) (GPa)

30 kN

Modulus of

Rigidity G

(GPa)

dy

0₂

% Elongation in Poisson's

50 mm specimen Ratio v

Coef. of Therm.

Expansion a

(10-)/°C

Tens.

Comp. Shear Tens.

Comp. Shear

Metallic

2.79

2014-T6

Aluminum

Wrought Alloys 6061-T6

73.1

68.9

27

26

414

255

414 172 469

255 131 290

469 290

290 186

669

10

12

0.35

0.35

23

24

2.71

7.19

67.0

27

179

-

0.6

0.28

12

7.28

172

68

276

572

5

0.28

12

Cast Iron

Alloys

Copper-Red Brass C83400

Alloys Bronze C86100

8.74

101

37

70.0 70.0

241

241

35

0.35

18

8.83

103

38

345

345

655

20

0.34

17

-

655

276

Magnesium

Alloy

[Am 1004-T61]

1.83

44.7

18

152

152

276

152

1

0.30

26

7.85

200

75

250 250

400

30

0.32

12

400

450

7.85

200

75

345

345

-

450

30

0.32

12

Steel

Alloys

7.86

193

75

207

207

517

517

40

0,27

17

8.16

200

75

703

703

800 800

22

0.32

12

Titanium

Alloy

4.43

120

44

924

924

1,000

1,000

16

0.36

9.4

2.38

22.1

0.15

11

Concrete

2.37

29.0

0.15

11

1.45

131

717

483 20.3

2.8

0.34

-

Plastic

Reinforced

1.45

72.4

90

131

0.34

-Douglas Fir

Wood

Select Structural

0.47

13.1

2.1c 264

6.24

0.29€

White Spruce

3.60

9.65

2.5⁰

36d

6.7⁰

0.31€

Grade

"Specific values may vary for a particular material due to alloy or mineral composition mechanical working of the specimen,or heat treatment. For a more exact value

reference books for the material should be consulted.

The yield and ultimate strengths for ductile materials can be assumed equal for both tension and compression.

Measured perpendicular to the grain.

d Measured parallel to the grain.

*Deformation measured perpendicular to the grain when the load is applied along the grain.

Gray ASTM 20

Malleable ASTM A-197

Structural A-36

Structural A992

Stainless 304

Tool L2

[Ti-6AI-4V]

Nonmetallic

Low Strength

High Strength

-Kevlar 49

30% Glass

FIFTIE

TUTT

12

38](/v2/_next/image?url=https%3A%2F%2Fcontent.bartleby.com%2Fqna-images%2Fquestion%2F2522e541-6825-4054-8c7b-75adee119910%2F249a07af-a1cc-43cd-ad1f-4e5f0fd40c4b%2Frj4mfio_processed.png&w=3840&q=75)

Transcribed Image Text:50 mm

a

a

T

A 150 mm

50 mm

Section a-a

300 mm

Soal Hibbler F9-11

Sebuah batang tanpa massa mempunyai penampang berbentuk balok seperti pada gambar. Batang terbuat dari

Cast Iron Gray ASTM 20. Pada kondisi pembebanan seperti pada gambar dengan angka keamanan n = 3, apakah

pada point A akan mengalami retak ?

Yield Strength (MPa) Ultimate Strength (MPa)

Materials

Moduls of

Density p Elasticity E

(Mg/m³) (GPa)

30 kN

Modulus of

Rigidity G

(GPa)

dy

0₂

% Elongation in Poisson's

50 mm specimen Ratio v

Coef. of Therm.

Expansion a

(10-)/°C

Tens.

Comp. Shear Tens.

Comp. Shear

Metallic

2.79

2014-T6

Aluminum

Wrought Alloys 6061-T6

73.1

68.9

27

26

414

255

414 172 469

255 131 290

469 290

290 186

669

10

12

0.35

0.35

23

24

2.71

7.19

67.0

27

179

-

0.6

0.28

12

7.28

172

68

276

572

5

0.28

12

Cast Iron

Alloys

Copper-Red Brass C83400

Alloys Bronze C86100

8.74

101

37

70.0 70.0

241

241

35

0.35

18

8.83

103

38

345

345

655

20

0.34

17

-

655

276

Magnesium

Alloy

[Am 1004-T61]

1.83

44.7

18

152

152

276

152

1

0.30

26

7.85

200

75

250 250

400

30

0.32

12

400

450

7.85

200

75

345

345

-

450

30

0.32

12

Steel

Alloys

7.86

193

75

207

207

517

517

40

0,27

17

8.16

200

75

703

703

800 800

22

0.32

12

Titanium

Alloy

4.43

120

44

924

924

1,000

1,000

16

0.36

9.4

2.38

22.1

0.15

11

Concrete

2.37

29.0

0.15

11

1.45

131

717

483 20.3

2.8

0.34

-

Plastic

Reinforced

1.45

72.4

90

131

0.34

-Douglas Fir

Wood

Select Structural

0.47

13.1

2.1c 264

6.24

0.29€

White Spruce

3.60

9.65

2.5⁰

36d

6.7⁰

0.31€

Grade

"Specific values may vary for a particular material due to alloy or mineral composition mechanical working of the specimen,or heat treatment. For a more exact value

reference books for the material should be consulted.

The yield and ultimate strengths for ductile materials can be assumed equal for both tension and compression.

Measured perpendicular to the grain.

d Measured parallel to the grain.

*Deformation measured perpendicular to the grain when the load is applied along the grain.

Gray ASTM 20

Malleable ASTM A-197

Structural A-36

Structural A992

Stainless 304

Tool L2

[Ti-6AI-4V]

Nonmetallic

Low Strength

High Strength

-Kevlar 49

30% Glass

FIFTIE

TUTT

12

38

Expert Solution

Step 1: Given and required

Step by step

Solved in 4 steps with 3 images

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:

9781118170519

Author:

Norman S. Nise

Publisher:

WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:

9781118807330

Author:

James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:

WILEY