Concept explainers

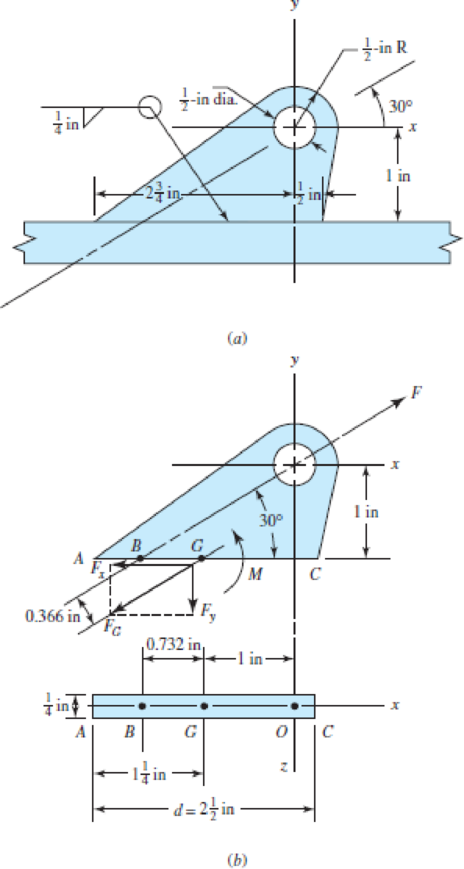

Brackets, such as the one shown, are used in mooring small watercraft. Failure of such brackets is usually caused by bearing pressure of the mooring clip against the side of the hole. Our purpose here is to get an idea of the static and dynamic margins of safety involved. We use a bracket 1/4 in thick made of hot-rolled 1018 steel, welded with an E6010 electrode. We then

assume wave action on the boat will create force F no greater than 1200 lbf.

(a) Determine the moment M of the force F about the centroid of the weld G. This moment produces a shear stress on the throat resisting bending action with a “tension” at A and “compression” at C.

(b) Find the force component Fy that produces a shear stress at the throat resisting a “tension” throughout the weld.

(c) Find the force component Fx that produces an in-line shear throughout the weld.

(d) Using Table 9–2, determine A, Iu, and I for the bracket.

(e) Find the shear stress τ1 at A due to Fy and M, the shear stress τ2 due to Fx, and combine to find τ.

(f) Find the factor of safety guarding against shear yielding in the weldment. Since the weld material is comprised of a mix of the electrode material and the base material, take the conservative approach of utilizing the strength of the weaker material.

(g) Find the factor of safety guarding against a static failure in the parent metal at the weld.

(h) Assuming the force F alternates between zero and 1200 lbf, find the factor of safety guarding against a fatigue failure in the weld metal using a Gerber failure criterion.

(a)

The moment

Answer to Problem 52P

The moment

Explanation of Solution

Write the expression for moment about

Here, force is

Conclusion:

Substitute

Thus, the moment

(b)

The force component

Answer to Problem 52P

The force component

Explanation of Solution

Write the expression for component of force

Here, force is

Conclusion:

Substitute

Thus, the force component

(c)

The force component

Answer to Problem 52P

The force component

Explanation of Solution

Write the expression for component of force

Here, force is

Conclusion:

Substitute

Thus, the force component

(d)

The area of throat, unit second moment of area and second area moment by using the Table

Answer to Problem 52P

The throat area is

The unit second moment of area is

The second area moment is

Explanation of Solution

Write the expression for throat area.

Here, thickness of weld is

Write the expression for unit second moment of area.

Here, thickness of weld is

Write the expression for second area moment about an axis

Here, thickness of weld is

Conclusion:

Substitute

Thus, the throat area is

Substitute

Thus, the unit second moment of area is

Substitute

Thus, second area moment is

(e)

The shear stress

The shear stress

The combined maximum shear stress

Answer to Problem 52P

The shear stress

The shear stress

The maximum shear stress is

Explanation of Solution

Write the expression for shear stress due to

Here, force in y-direction is

Write the expression for shear stress due to

Here, force in x-direction is

Write the expression for resultant shear stress at the throat plane.

Here, shear stress due to

Write the expression for secondary shear stress.

Here, Moment is

Write the expression for maximum shear stress.

Here, resultant shear stress at the throat plane is

Conclusion:

Substitute

Thus, the shear stress

Substitute

Thus, the shear stress

Substitute

Substitute

Substitute

Thus, the maximum shear stress is

(f)

The factor of safety guarding against shear yielding in the weldment.

Answer to Problem 52P

The factor of safety guarding against shear yielding in the weldment is

Explanation of Solution

Write the expression for factor of safety against guiding against shear yielding in weldment.

Here, yield stress is

Conclusion:

Refer to member of

Substitute

Thus, the factor of safety guarding against shear yielding in the weldment is

(g)

The factor of safety guarding against a static failure in the parent metal at the weld.

Answer to Problem 52P

The factor of safety guarding against a static failure in the parent metal at the weld is

Explanation of Solution

Write the expression for shear stress.

Here, force along x-direction is

Write the expression for normal stress along y-direction.

Here, force along x-direction is

Write the expression for von misses stress theory.

Here, normal stress is

Write the expression for factor of safety.

Here, yield stress is

Conclusion:

Substitute

Substitute

Substitute

Substitute

Thus, the factor of safety guarding against a static failure in the parent metal at the weld is

(h)

The factor of safety guarding against a fatigue failure in the weld metal using Gerber failure criterion.

Answer to Problem 52P

The factor of safety guarding against a fatigue failure in the weld metal using Gerber failure criterion is

Explanation of Solution

Write the expression for surface factor.

Here, ultimate tensile strength is

Write the expression for effective diameter.

Here, thickness of weld is

Write the expression for size factor.

Here, effective diameter is

Write the expression for equivalent strength.

Here, ultimate tensile strength is

Write the expression for endurance limit.

Here, surface factor is

Write the expression for axial shear stress.

Here, surface factor for shear is

Write the expression for factor of safety of Gerber criterion.

Here, maximum shear is

Conclusion:

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Substitute

Thus, the factor of safety guarding against a fatigue failure in the weld metal using Gerber failure criterion is

Want to see more full solutions like this?

Chapter 9 Solutions

Shigley's Mechanical Engineering Design (McGraw-Hill Series in Mechanical Engineering)

- 4. Figure 1 shows a pump and pipe network being used to transport heptane at 120°F to a large, elevated, closed storage tank. The tank is pressurized and maintained at 18 psia. The volumetric flow rate of the heptane is 500 gpm. a. Specify the nominal diameter of the check valve. b. Determine the pump discharge pressure required (psia) to move the heptane through the discharge pipe. Plank = 18 psia Liquid level Large pressurized storage tank 40 ft All pipes are 6-nom sch 40 commercial steel Standard 90° elbows and 180° bend Total length of straight pipe = 115 ft Class 300 swing check valve INH Pump Figure 1: Pressurized storage tank systemarrow_forward2. In a particular section of a fluid system, a 30% ethylene glycol mixture is flowing through a 6- nom xs cast iron pipe at a temperature of 0°C. In this section of piping, the velocity must be maintained in the range 1.5 m/sarrow_forward1. Steam leaves the boiler of a power plant at 5 MPa, 500°C as shown in the following figure. As the steam passes to the turbine, the temperature drops to 496°C before it enters the turbine due to a heat loss through the pipe's insulation. The pressure drop in the pipe connecting the boiler to the turbine is negligible. The steam then passes through an adiabatic turbine and exits at 10 kPa. The turbine has an isentropic efficiency of 85% and is delivering 1000 MW of power. Determine the following. P = 5 MPa T₁ = 500°C Boiler P₁₂ =5 MPa Τ =496°C 7 = 85% W = 1,000 MW P=1 atm To=25°C Turbine 3+ P = 10 kPa a. The heat transfer rate from the pipe connecting the boiler to the turbine (in MW) b. The change in flow exergy rate as the steam flows through the pipe (MW). This represents exergy that is lost to the environment and unavailable for power delivery. Comment on the magnitude of this exergy loss compared to the power delivered by the turbine. What factor(s) would warrant better…arrow_forwardAn aluminum rod of length L = 1m has mass density p = 2700 kg and Young's modulus E = 70 GPa. The rod is fixed at both ends. The exact natural eigenfrequencies of the rod are wexact E = √ ρ for n=1,2,3,. . . . 1. What is the minimum number of linear elements necessary to determine the fundamental frequency w₁ of the system? Discretize the rod in that many elements of equal length, assemble the global system of equations KU = w² MU, and find the fundamental frequency w₁. Compute the relative error e₁ = (w1 - wexact) /w exact Sketch the fundamental mode of vibration. 2. Use COMSOL to solve the same problem. Show the steps necessary to find the fundamental frequency and mode of the rod. What is the relative error using linear elements and a normal mesh?arrow_forwardA ball with a mass of 5.0 kg is hanging from a string and is initially at rest. A bullet with a mass of 10.0 g and a velocity of 200.0 m/s is fired at the ball. The bullet embeds itself inside the ball. How high (h) do the ball and the bullet rise? Gravitational acceleration: g=9.81g = 9.81g=9.81 m/s².arrow_forwardDon't use chatgpt. Need handwritten solution. Mechanical engineeringarrow_forwardMechanical engineering question.arrow_forwardA shaft is loaded in bending and torsion such that Ma = 70 N·m, T₁ = 45 N · m, M = 55 N. m, and T = 35 N m. For the shaft, S₁ = 700 MPa and S = 560 MPa, and a fully corrected endurance limit of S₂ = 210 MPa is assumed. Let K = 2.2 and K = 1.8. With a Se design factor of 2.0 determine the minimum acceptable diameter of the shaft using the a) DE- Goodman b) DE-Morrow c) DE-Gerber d) DE-SWTarrow_forwardThe feed flow rate to an adiabatic continuous stirred tank reactor (CSTR) in which an exothermicreaction is occurring is increased from 1000 to 1400. kg/h, causing the outlet temperature to change as shown:a) Briefly explain on a physical basis why the temperature in this system oscillates after a step increasein the inlet flow rate. Be clear, complete, and concise. c) You know that this oscillating response cannot be that of two first order processes with real timeconstant acting in series. Assuming the reaction is first order and the CSTR operates with constant holdup,derive the block diagram with all transfer functions indicating how the temperature would respond to the feedflow rate step change (W’(s) as input and T’(s) as output). An intermediate variable in this block diagram willbe the concentration of A in the reactor, represented by CA’(s). d) A correct result for part c) will include a feedback loop in the block diagram, indicating the responsein T to a change in w is not…arrow_forwardSpur gears Note : Exam is open notes &tables / Answer all questions. Q.1. The press shown for Figure.1 has a rated load of 22 kN. The twin screws have double start Acme threads, a diameter of 50 mm, and a pitch of 6 mm. Coefficients of friction are 0.05 for the threads and 0.08 for the collar bearings. Collar diameters are 90 mm. The gears have an efficiency of 95 percent and a speed ratio of 60:1. A slip clutch, on the motor shaft, prevents overloading. The full-load motor speed is 1720 rev/min. (a) When the motor is turned on, how fast will the press head move? (Vm= , Vser. = ) (5M) (b) What should be the horsepower rating of the motor? (TR=, Tc= Pser. = " Bronze bushings Foot Motor Bearings watt, Pm= watt, Pm= h.p.) (20M) 2['s Fig.1 Worm Collar bearingarrow_forwardProblem 2 (55 pts). We now consider the FEM solution of Problem 1.(a) [5pts] Briefly describe the 4 steps necessary to obtain the approximate solution of thatBVP using the Galerkin FEM. Use the minimum amount of math necessary to supportyour explanations.(b) [20pts] Derive the weak form of the BVP.(c) [10pts] Assuming a mesh of two equal elements and linear shape functions, sketch byhand how you expect the FEM solution to look like. Also sketch the analytical solutionfor comparison. In your sketch, identify the nodal degrees of freedom that the FEMsolution seeks to find.(d) [10pts] By analogy with the elastic rod problem and heat conduction problem considered in class, write down the stiffness matrix and force vector for each of the twoelements considered in (c).(e) [10pts] Assemble the global system of equations, and verbally explain how to solve it.arrow_forwardAn aluminum rod of length L = 1m has mass density ρ = 2700 kgm3 andYoung’s modulus E = 70GPa. The rod is fixed at both ends. The exactnatural eigenfrequencies of the rod are ωexactn =πnLqEρfor n=1,2,3,. . . .1. What is the minimum number of linear elements necessary todetermine the fundamental frequency ω1 of the system? Discretizethe rod in that many elements of equal length, assemble the globalsystem of equations KU = ω2MU, and find the fundamentalfrequency ω1. Compute the relative error e1 = (ω1 − ωexact1)/ωexact1.Sketch the fundamental mode of vibration.arrow_forwardarrow_back_iosSEE MORE QUESTIONSarrow_forward_ios

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning