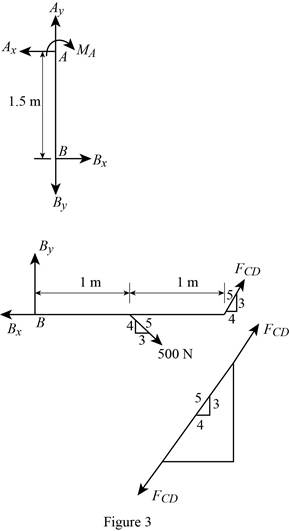

In each case, identify any two-force members, and then draw the free body diagrams of each member of the frame.

Prob. P6-3

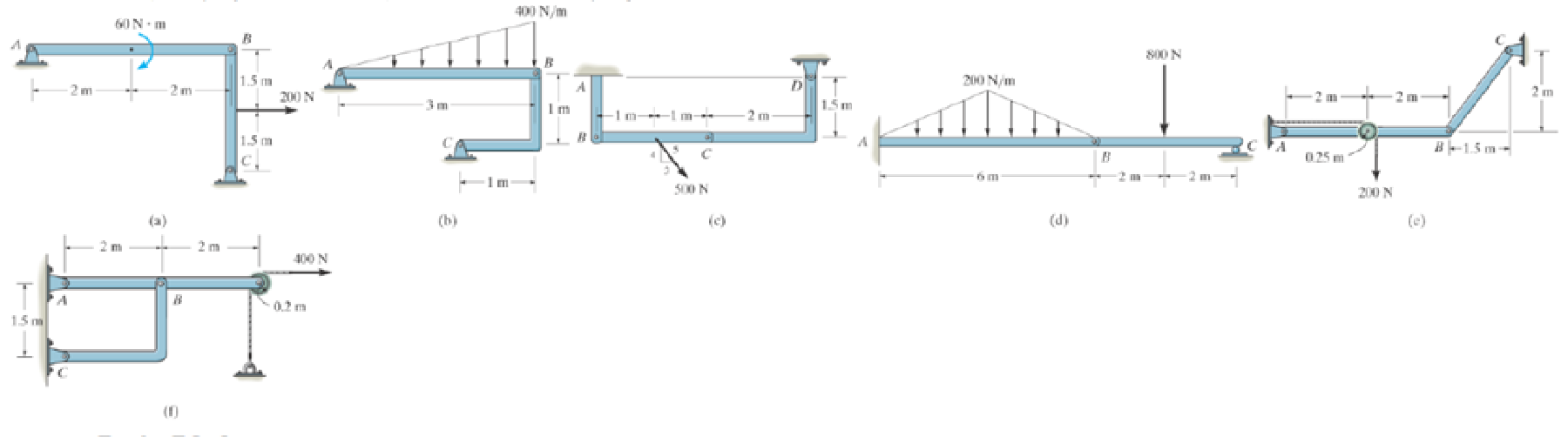

(a)

To identify and draw: The two force members and the free body diagrams of each member of the frame.

Explanation of Solution

Assumptions:

- Consider the state of member as tension where the force is pulling the member and as compression where the force is pushing the member.

- Consider the force indicating right side as positive and left side as negative in horizontal components of forces.

- Consider the force indicating upside is taken as positive and downside as negative in vertical components of forces.

Show the free body diagram of the member of the frame as in Figure (1).

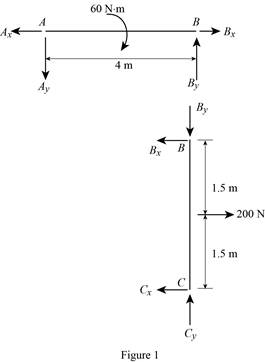

(b)

To identify and draw: The two force members and the free body diagrams of each member of the frame.

Explanation of Solution

Assumptions:

- Consider the state of member as tension where the force is pulling the member and as compression where the force is pushing the member.

- Consider the force indicating right side as positive and left side as negative in horizontal components of forces.

- Consider the force indicating upside is taken as positive and downside as negative in vertical components of forces.

The member CB is a two force member.

Show the free body diagram of the members of the frame as in Figure (2).

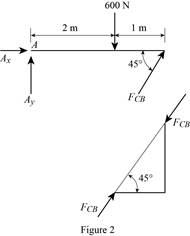

(c)

To identify and draw: The two force members and the free body diagrams of each member of the frame.

Explanation of Solution

Assumptions:

- Consider the state of member as tension where the force is pulling the member and as compression where the force is pushing the member.

- Consider the force indicating right side as positive and left side as negative in horizontal components of forces.

- Consider the force indicating upside is taken as positive and downside as negative in vertical components of forces.

The member CD is a two force member.

Show the free body diagram of the members of the frame as in Figure (3).

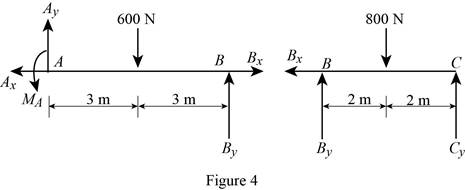

(d)

To identify and draw: The two force members and the free body diagrams of each member of the frame.

Explanation of Solution

Assumptions:

- Consider the state of member as tension where the force is pulling the member and as compression where the force is pushing the member.

- Consider the force indicating right side as positive and left side as negative in horizontal components of forces.

- Consider the force indicating upside is taken as positive and downside as negative in vertical components of forces.

Show the free body diagram of the members of the frame as in Figure (4).

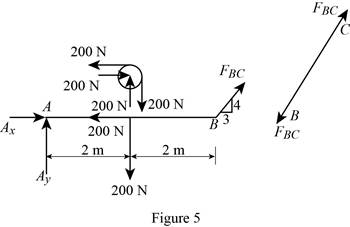

(e)

To identify and draw: The two force members and the free body diagrams of each member of the frame.

Explanation of Solution

Assumptions:

- Consider the state of member as tension where the force is pulling the member and as compression where the force is pushing the member.

- Consider the force indicating right side as positive and left side as negative in horizontal components of forces.

- Consider the force indicating upside is taken as positive and downside as negative in vertical components of forces.

The member BC is a two force member.

Show the free body diagram of the members of the frame as in Figure (5).

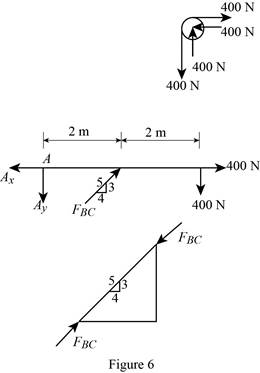

(f)

To identify and draw: The two force members and the free body diagrams of each member of the frame.

Explanation of Solution

Assumptions:

- Consider the state of member as tension where the force is pulling the member and as compression where the force is pushing the member.

- Consider the force indicating right side as positive and left side as negative in horizontal components of forces.

- Consider the force indicating upside is taken as positive and downside as negative in vertical components of forces.

The member BC is a two force member.

Show the free body diagram of the members of the frame as in Figure (5).

Want to see more full solutions like this?

Chapter 6 Solutions

ENGINEERING MECHANICS

Additional Engineering Textbook Solutions

Starting Out with Programming Logic and Design (5th Edition) (What's New in Computer Science)

Starting Out with Python (4th Edition)

Starting Out with Java: From Control Structures through Objects (7th Edition) (What's New in Computer Science)

Mechanics of Materials (10th Edition)

Degarmo's Materials And Processes In Manufacturing

Java: An Introduction to Problem Solving and Programming (8th Edition)

- auto controlsarrow_forward1 Pleasearrow_forwardA spring cylinder system measures the pressure. Determine which spring can measure pressure between 0-1 MPa with a large excursion. The plate has a diameter of 20 mm. Also determine the displacement of each 0.1 MPa step.Spring power F=c x fF=Springpower(N)c=Spring constant (N/mm)f=Suspension (mm) How do I come up with right answer?arrow_forward

- A lift with a counterweight is attached to the ceiling. The attachment is with 6 stainless and oiled screws. What screw size is required? What tightening torque? - The lift weighs 500 kg and can carry 800 kg. - Counterweight weight 600 kg - Durability class 12.8 = 960 MPa- Safety factor ns=5+-Sr/Fm= 0.29Gr =0.55arrow_forwardKnowing that a force P of magnitude 750 N is applied to the pedal shown, determine (a) the diameter of the pin at C for which the average shearing stress in the pin is 40 MPa, (b) the corresponding bearing stress in the pedal at C, (c) the corresponding bearing stress in each support bracket at C. 75 mm 300 mm- mm A B P 125 mm 5 mm C Darrow_forwardAssume the B frame differs from the N frame through a 90 degree rotation about the second N base vector. The corresponding DCM description is: 1 2 3 4 5 6 9 # adjust the return matrix values as needed def result(): dcm = [0, 0, 0, 0, 0, 0, 0, 0, 0] return dcmarrow_forward

- Find the reaction at A and B The other response I got was not too accurate,I need expert solved answer, don't use Artificial intelligence or screen shot it solvingarrow_forwardNo chatgpt plsarrow_forwardSolve for the reaction of all the forces Don't use artificial intelligence or screen shot it, only expert should solvearrow_forward

- No chatgpt plsarrow_forwardA six cylinder petrol engine has a compression ratio of 5:1. The clearance volume of each cylinder is 110CC. It operates on the four-stroke constant volume cycle and the indicated efficiency ratio referred to air standard efficiency is 0.56. At the speed of 2400 rpm. 44000KJ/kg. Determine the consumes 10kg of fuel per hour. The calorific value of fuel average indicated mean effective pressure.arrow_forwardThe members of a truss are connected to the gusset plate as shown in (Figure 1). The forces are concurrent at point O. Take = 90° and T₁ = 7.5 kN. Part A Determine the magnitude of F for equilibrium. Express your answer to three significant figures and include the appropriate units. F= 7.03 Submit ? kN Previous Answers Request Answer × Incorrect; Try Again; 21 attempts remaining ▾ Part B Determine the magnitude of T2 for equilibrium. Express your answer to three significant figures and include the appropriate units. Figure T₂ = 7.03 C T2 |? KN Submit Previous Answers Request Answer × Incorrect; Try Again; 23 attempts remaining Provide Feedbackarrow_forward

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY