Concept explainers

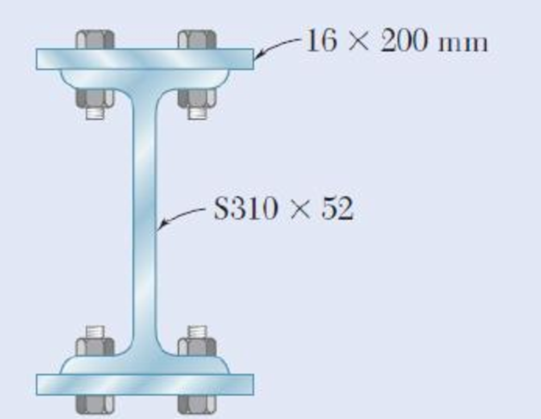

The American Standard rolled-steel beam shown has been reinforced by attaching to it two 16 × 200-mm plates, using 18-mm-diameter bolts spaced longitudinally every 120 mm. Knowing that the average allowable shearing stress in the bolts is 90 MPa, determine the largest permissible vertical shearing force.

The largest permissible vertical shearing force.

Answer to Problem 5P

The largest permissible vertical shearing force is

Explanation of Solution

Given information:

The diameter of bolt is

The longitudinal spacing is

The average shearing stress in the bolts is

Calculation:

Provide the section properties of the rolled steel beam

The area of the section is

The moment of inertia of the section

The Overall depth of the member

Calculate the moment of inertia as shown below.

Here, b is the breadth of the beam, h is the height of the beam, A is the area of the beam, and

For the top plate.

Calculate the area

Calculate the location of the centroid

Similarly calculate the moment of inertia for the bottom plate and rolled steel beam

| Part | Area, | Moment of Inertia, | ||

| Top plate | ||||

| Bottom plate |

Calculate the moment of inertia for the whole section as shown below.

Calculate the first moment of area

Substitute

Calculate the area of bolt as shown below.

Here,

Substitute

Calculate the force acting on the bolt

Here,

Substitute

Calculate the horizontal shear per unit length as shown below.

Substitute

Calculate the vertical shearing force (V) as shown below.

Substitute

Therefore, the largest permissible vertical shearing force is

Want to see more full solutions like this?

Chapter 6 Solutions

EBK MECHANICS OF MATERIALS

- Can you solve it analytically using laplace transforms and with Matlab code as well please. Thank You.arrow_forwardQ11. Determine the magnitude of the reaction force at C. 1.5 m a) 4 KN D b) 6.5 kN c) 8 kN d) e) 11.3 KN 20 kN -1.5 m- C 4 kN -1.5 m B Mechanical engineering, No Chatgpt.arrow_forwardplease help with this practice problem(not a graded assignment, this is a practice exam), and please explain how to use sohcahtoaarrow_forward

- Solve this problem and show all of the workarrow_forwardSolve this problem and show all of the workarrow_forwardaversity of Baoyion aculty of Engineering-AIMusyab Automobile Eng. Dep. Year: 2022-2023, st Course, 1st Attempt Stage: 3rd Subject: Heat Transfer I Date: 2023\01\23- Monday Time: 3 Hours Q4: A thick slab of copper initially at a uniform temperature of 20°C is suddenly exposed to radiation at one surface such that the net heat flux is maintained at a constant value of 3×105 W/m². Using the explicit finite-difference techniques with a space increment of Ax = = 75 mm, determine the temperature at the irradiated surface and at an interior point that is 150 mm from the surface after 2 min have elapsed. Q5: (12.5 M) A) A steel bar 2.5 cm square and 7.5 cm long is initially at a temperature of 250°C. It is immersed in a tank of oil maintained at 30°C. The heat-transfer coefficient is 570 W/m². C. Calculate the temperature in the center of the bar after 3 min. B) Air at 90°C and atmospheric pressure flows over a horizontal flat plate at 60 m/s. The plate is 60 cm square and is maintained at a…arrow_forward

- University of Baby on Faculty of Engineering-AIMusyab Automobile Eng. Dep. Year: 2022-2023. 1 Course, 1" Attempt Stage 3 Subject Heat Transfer I Date: 2023 01 23- Monday Time: 3 Hours Notes: Q1: • • Answer four questions only Use Troles and Appendices A) A flat wall is exposed to an environmental temperature of 38°C. The wall is covered with a layer of insulation 2.5 cm thick whose thermal conductivity is 1.4 W/m. C, and the temperature of the wall on the inside of the insulation is 315°C. The wall loses heat to the environment by convection. Compute the value of the convection heat-transfer coefficient that must be maintained on the outer surface of the insulation to ensure that the outer-surface temperature does not exceed 41°C. B) A vertical square plate, 30 cm on a side, is maintained at 50°C and exposed to room air at 20°C. The surface emissivity is 0.8. Calculate the total heat lost by both sides of the plate. (12.5 M) Q2: An aluminum fin 1.5 mm thick is placed on a circular tube…arrow_forwardSolve using graphical method and analytical method, only expert should solvearrow_forwardSolve this and show all of the workarrow_forward

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY