Concept explainers

(a)

Maximum permissible load using LFRD method.

Answer to Problem 5.5.1P

The maximum permissible load from LFRD method is

Explanation of Solution

Given information:

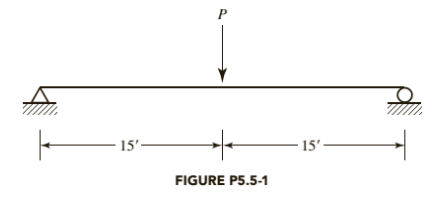

A W 10X 77 has continuous lateral support. The load P is a service live load and

Following is the given beam:

Calculation:

We have following properties for W 10X 77 from ASIC manual

| DesignationImperial (in x lb/ft) | Depth h (in) | Width w (in) | Web Thickness tw (in) | Flange Thickness tf (in) | Sectional Area (in2) | Weight (lbf/ft) | Static Parameters | ||||

| Moment of Inertia | Elastic Section Modulus | ||||||||||

| Ix (in4) | Iy (in4) | Sx (in3) | Sy (in3) | ||||||||

| W 10 x 77 | 10.60 | 10.190 | 0.530 | 0.870 | 22.6 | 77 | 455 | 154 | 85.9 | 30.1 | |

Let’s check for the compactness of the given W-shape beam using part

For Flange:

Where,

If the above condition satisfies, then the flange is non compact for flexure

Therefore, the web is compact.

Calculate the nominal flexural strength using the formula

Where,

Manual.

Now, calculate the maximum bending moment due to dead load, we have

Maximum bending moment for a simply supported beam carrying a dead UDL

Where,

Substitute,

Calculate the maximum bending moment for a simply supported beam carrying a concentrated

live load of the beam:

Where, P is the concentrated load and L is the length of the beam is.

Now, using Load Resistance and Factored design method:

Calculate the maximum permissible load P.

Substitute

Calculate P, by equating the maximum bending moment with the flexural strength of the beam;

Where,

Substitute

Conclusion:

Therefore, the maximum permissible load from LFRD method is

(b)

Maximum permissible load using ASD method.

Answer to Problem 5.5.1P

The maximum permissible load from ASD method is

Explanation of Solution

Given information:

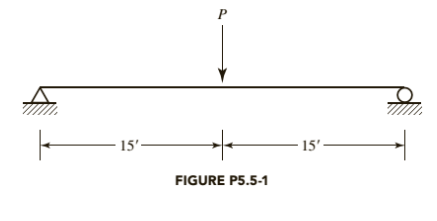

A W 10X 77 has continuous lateral support. The load P is a service live load and

Calculation:

We have following properties for W 10X 77 from ASIC manual

| DesignationImperial (in x lb/ft) | Depthh (in) | Widthw (in) | Web Thicknesstw (in) | Flange Thicknesstf (in) | Sectional Area (in2) | Weight (lbf/ft) | Static Parameters | ||||

| Moment of Inertia | Elastic Section Modulus | ||||||||||

| Ix (in4) | Iy (in4) | Sx (in3) | Sy (in3) | ||||||||

| W 10 x 77 | 10.60 | 10.190 | 0.530 | 0.870 | 22.6 | 77 | 455 | 154 | 85.9 | 30.1 | |

Let’s check for the compactness of the given W-shape beam using part

For Flange:

Where,

If the above condition satisfies, then the flange is non compact for flexure

Therefore, the web is compact.

Calculate the nominal flexural strength using the formula

Now, calculate the maximum bending moment due to dead load, we have

Maximum bending moment for a simply supported beam carrying a dead UDL

Where,

Substitute,

Calculate the maximum bending moment for a simply supported beam carrying a concentrated

live load of the beam:

Where, P is the concentrated load and L is the length of the beam is.

Calculate the uniformly distributed load on the beam by equating

Allowable stress design method:

Substitute

Calculate P, by equating the maximum bending moment with the flexural strength of the beam:

Substitute,

Conclusion:

Therefore, the maximum permissible load from ASD method is

Want to see more full solutions like this?

Chapter 5 Solutions

Bundle: Steel Design, Loose-leaf Version, 6th + Mindtap Engineering, 1 Term (6 Months) Printed Access Card

- A mechanism for pushing small boxes from an assembly line onto a conveyor belt is shown with arm OD and crank CB in their vertical positions. For the configuration shown, crank CB has a constant clockwise angular velocity of 0.6π rad/s. Determine the acceleration QE of E (positive if to the right, negative if down). 450 mm 215 mm 565 mm A 185 mm 105 mm 110185. mm mm Answer: a = i B 40 mm E m/s²arrow_forwardPlease answer the following questions in the picture, use the second picture to answer some of the questions. I appreciate your help! Explain step by step, thank you!arrow_forwardQuestion 5. Three pipes A, B, and C are interconnected as in Fig. 2. The pipe characteristics are given below. Find the rate at which water will flow in each pipe. Find also the pressure at point P. (Neglect minor losses) Pipe D (in) L (ft) f A 6 2000 0.020 B 4 1600 0.032 C 8 3000 0.02 -El. 200 ft P -El. 120 ft B Fig. 2 -El. 50 ft.arrow_forward

- calculate all nodal displacementts and all the member forces of the trussarrow_forwardNOTE: Use areal methods only for V,M,N diagrams(Do NOT use the equations) (also draw the N diagram(s) for the entire structure)arrow_forwardThe figure below shows a foundation of 10 ft x 6.25 ft resting on a sand deposit. The net load per unit area at the level of the foundation, qo, is 2100 lb/ft². For the sand, μs = 0.3, E, = 3200 lb/in.², Dƒ = 2.5 ft, and H = 32 ft. Foundation BX L Rigid foundation settlement Flexible foundation settlement H μ, Poisson's ratio E, = Modulus of elasticity Soil Rock Elastic settlement of flexible and rigid foundations Table 1 Variation of F₁ with m' and n' m' n' 1.0 1.2 1.4 1.6 1.8 2.0 2.5 3.0 0.25 0.014 0.013 0.012 0.011 0.011 0.011 0.010 0.010 0.50 0.049 0.046 0.044 0.042 0.041 0.040 0.038 0.038 1.00 0.142 0.138 0.134 0.130 0.127 0.125 0.121 0.118 2.00 0.285 0.290 0.292 0.292 0.291 0.289 0.284 0.279 5.00 0.437 0.465 0.487 0.503 0.516 0.526 0.543 0.551 10.00 0.498 0.537 0.570 0.597 0.621 0.641 0.679 0.707 20.00 0.529 0.575 0.614 0.647 0.677 0.702 0.756 0.797 50.00 0.548 0.598 0.640 0.678 0.711 0.740 0.803 0.853 100.00 0.555 0.605 0.649 0.688 0.722 0.753 0.819 0.872 Table 2 Variation of F2…arrow_forward

- = == An 8 m high retaining wall supports a 5.5 m deep sand (Ya 18.5 kN/m³, q = 34°) overlying a saturated sandy clay (y_sat = 20.3 kN/m³, q = 28°, c = 17 kPa). The groundwater level is located at the interface of two layers. Sketch the lateral stress distribution up to a depth of 8 m for an active condition. Also, determine the line of action of the resultant. 5.5 m Sand |Y=18.5 kN/m³ |₁ =34° Sandy : clay 2.5 m |c=17 kPa Ysat 20.3 kN/m³ 2=28°arrow_forward3. What is the maximum allowable load that can be applied to the pile shown below? : Qall = ? G.W.T. 45' Soft Clay: Ysat 100 pcf Cu = 500 psf, ou = 0° Clay Shale: Qu(lab) 24,000 psi o' = 15° Driven Steel H-Pile: 1/2" thick steel web & flanges (soil plugged) -10". I Note: Pile & soil profile are not drawn to scale Please use the approach outlined in Das 12.16 and an Allowable Stress Design (ASD) approach for your analysis. Use a factor of safety = 3 for design, neglect any effect that shaft resistance has on pile capacity, and neglect the effect of the weight of the pile in your analysis.arrow_forward2. Calculate the ultimate load carrying capacity of the pile tip driven into the soil profile shown below: G.W.T. Qapp 40' Soft Clay: Ysat 100 pcf Cu 500 psf, ₁ = 0° 4c+4 Poorly Graded Sand (SP): Ysat = 125 pcf Q₁ = ? c' = 0, ' = 35° Driven Steel Pipe Pile: Outside Diameter = 2' Inside Diameter = 1'11" Hollow (soil plugged) Note: Pile & soil profile are not drawn to scale For this problem, please calculate N₁* using both the bearing capacity theory approach and using standard design charts. Compare the values that result from these two approaches. Please use only the Nq* from bearing capacity theory for the remainder of your calculations.arrow_forward

- Design a fully restrained BFP moment connection to support the factored bending moment of 1,200 kN·m and factored shear force of 95 kN due to wind and gravity loads. Use 90mm spacing between the bolts, and 40mm edge spacing. The steel grade is A992 for the W920 × 201 beam and W840 × 359 column and A36 for the steel plate (30 mm thick). Use FEXX = 450 MPa electrodes and 20mm A490 bolts (threads included) for the flange plate (Fr= 457 MPa), 16mm A307 bolts for the shear tab (Fnv = 165 MPa). Steel Section Properties W920 × 201 W840 × 359 D₁ = 904 mm bf = 305 mm tf = 20.1 mm tw = 15.2 mm d = 869 mm bf = 404 mm tf = 35.6 mm tw = 21.1 mm Summary of answer: Flange Plate: bPL = tPL = No. of Bolts: Flange bolt = Thickness of fillet weld on shear tab:. Shear tab =arrow_forwardA6.1- A simply supported beam, as shown in Figure 3, is subjected to factored point load Pr= 1250 kN. The beam is designed to have 6-30M bars to resist the maximum bending moment, Mat the section 900 mm away from the centerline of the support. Determine the required development length for the reinforcement at the section with the maximum bending moment. If it is not possible to provide straight bar anchorage into the left support, design the hooked anchorage. Given: Concrete: Normal density with f'c = 25 MPa Reinforcement: Uncoated rebars with fy = 400 MPa Shear reinforcement is in excess of CSA 23.3 minimum requirement: 10M Clear cover to the stirrups: 30 mm Column: 200mm x 500mm m + 1 b=500 mm 200mm Σ Mf 6-30M Figure 3 10 m 200mm h=1000 mm + As = 6-30M Cross-sectionarrow_forwardP What's the stress increase, DUZ (induced stress) at point p according to the chart shown? Show work and mark the chart to demonstrate how you came up with an answer 36ff Qis 24f+ P (at depth 12ft) Point R is below Q, which is on the edge of the footing. 24 ft from one corner (thus 12 from the other). Show how to divide the area into two and use the principle of Super position to calculate stress increase (DJ₂) aka induced stress at R. Draw a plan view of Area I and Arca 2. Find L1, B₁, and 2, dimensions and indicate them accordingly on both Area 1 and Area 2 24f1 - 24ft •R (depth 12ft)arrow_forward

Steel Design (Activate Learning with these NEW ti...Civil EngineeringISBN:9781337094740Author:Segui, William T.Publisher:Cengage Learning

Steel Design (Activate Learning with these NEW ti...Civil EngineeringISBN:9781337094740Author:Segui, William T.Publisher:Cengage Learning Materials Science And Engineering PropertiesCivil EngineeringISBN:9781111988609Author:Charles GilmorePublisher:Cengage Learning

Materials Science And Engineering PropertiesCivil EngineeringISBN:9781111988609Author:Charles GilmorePublisher:Cengage Learning