Concept explainers

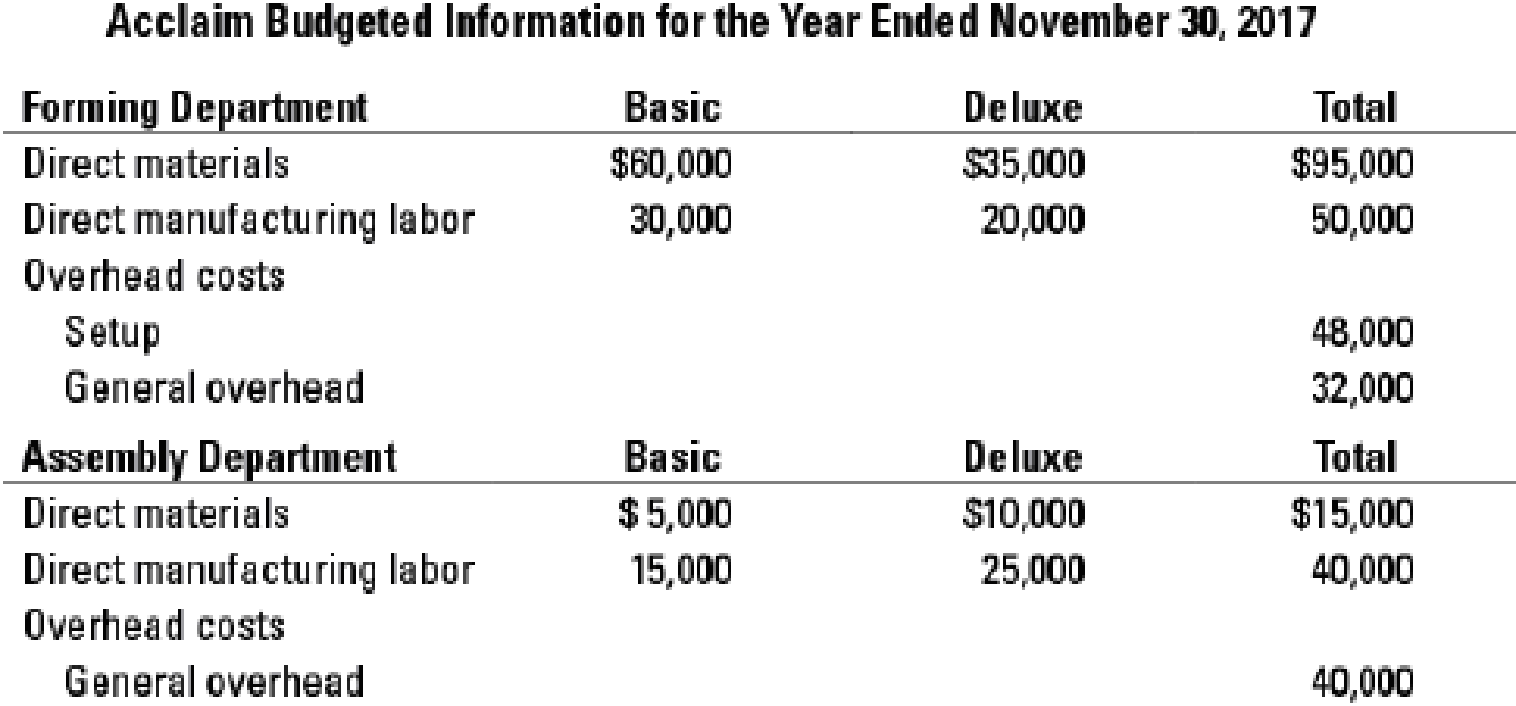

Plant-wide, department, and activity-cost rates. Acclaim Inc. makes two styles of trophies, basic and deluxe, and operates at capacity. Acclaim does large custom orders. Acclaim budgets to produce 10,000 basic trophies and 5,000 deluxe trophies. Manufacturing takes place in two production departments: forming and assembly. In the forming department, indirect

The controller has asked you to compare plant-wide, department, and activity-based cost allocation.

- 1. Calculate the budgeted unit cost of basic and deluxe trophies based on a single plant-wide overhead rate, if total overhead is allocated based on total direct costs. (Don’t forget to include direct material and direct manufacturing labor cost in your unit cost calculation.)

Required

- 2. Calculate the budgeted unit cost of basic and deluxe trophies based on departmental overhead rates, where forming department overhead costs are allocated based on direct manufacturing labor costs of the forming department and assembly department overhead costs are allocated based on total direct manufacturing labor costs of the assembly department.

- 3. Calculate the budgeted unit cost of basic and deluxe trophies if Acclaim allocates overhead costs in each department using activity-based costing, where setup costs are allocated based on number of batches and general overhead costs for each department are allocated based on direct manufacturing labor costs of each department.

- 4. Explain briefly why plant-wide, department, and activity-based costing systems show different costs for the basic and deluxe trophies. Which system would you recommend and why?

Trending nowThis is a popular solution!

Learn your wayIncludes step-by-step video

Chapter 5 Solutions

COST ACCOUNTING

Additional Business Textbook Solutions

Financial Accounting (12th Edition) (What's New in Accounting)

Fundamentals of Management (10th Edition)

Financial Accounting, Student Value Edition (5th Edition)

Horngren's Accounting (12th Edition)

Financial Accounting: Tools for Business Decision Making, 8th Edition

Horngren's Cost Accounting: A Managerial Emphasis (16th Edition)

- The direct labor price variance?arrow_forwardBoom Lay Corp, has a current accounts receivable balance of $327,815. Credit sales for the year just ended were $4,238,720. What is the receivables turnover? What is the day's sales in receivables? How long did it take on average for credit customers to pay off their accounts during the past year?(general Account)arrow_forwardPlease give me correct answer the accounting questionarrow_forward

- Engstom's direct labor costs for the month may?arrow_forwardProduction estimates for July for Starling Co. are as follows: Estimated inventory (units), July 1 8,500 Desired inventory (units), July 31 10,500 76,000 Expected sales volume (units), July For each unit produced, the direct materials requirements are as follows: Material A ($5 per lb.) 3 lbs. Material B ($18 per lb.) 0.5 lb. The total direct materials purchases of Materials A and B (assuming no beginning or ending materials inventory) required for July production are: a. $1,080,000 for A; $1,296,000 for B. b. $1,170,000 for A; $702,000 for B. c. $1,125,000 for A; $675,000 for B. d. $1,080,000 for A; $648,000 for B.arrow_forwardLast year, Brighton Corporation had... Please answer the general accounting questionarrow_forward

- Financial Accounting Question need helparrow_forwardProvide correct answer general accountingarrow_forwardHomestead Jeans Co. has an annual plant capacity of 65,000 units, and current production is 45,000 units. Monthly fixed costs are $54,000, and variable costs are $29 per unit. The present selling price is $42 per unit. On November 12 of the current year, the company received an offer from Dawkins Company for 18,000 units of the product at $32 each. Dawkins Company will market the units in a foreign country under its own brand name. The additional business is not expected to affect the domestic selling price or quantity of sales of Homestead Jeans Co. Calculate a differential analysis on whether to accept or reject the special offer.arrow_forward

Managerial AccountingAccountingISBN:9781337912020Author:Carl Warren, Ph.d. Cma William B. TaylerPublisher:South-Western College Pub

Managerial AccountingAccountingISBN:9781337912020Author:Carl Warren, Ph.d. Cma William B. TaylerPublisher:South-Western College Pub Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage LearningPrinciples of Accounting Volume 2AccountingISBN:9781947172609Author:OpenStaxPublisher:OpenStax College

Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage LearningPrinciples of Accounting Volume 2AccountingISBN:9781947172609Author:OpenStaxPublisher:OpenStax College