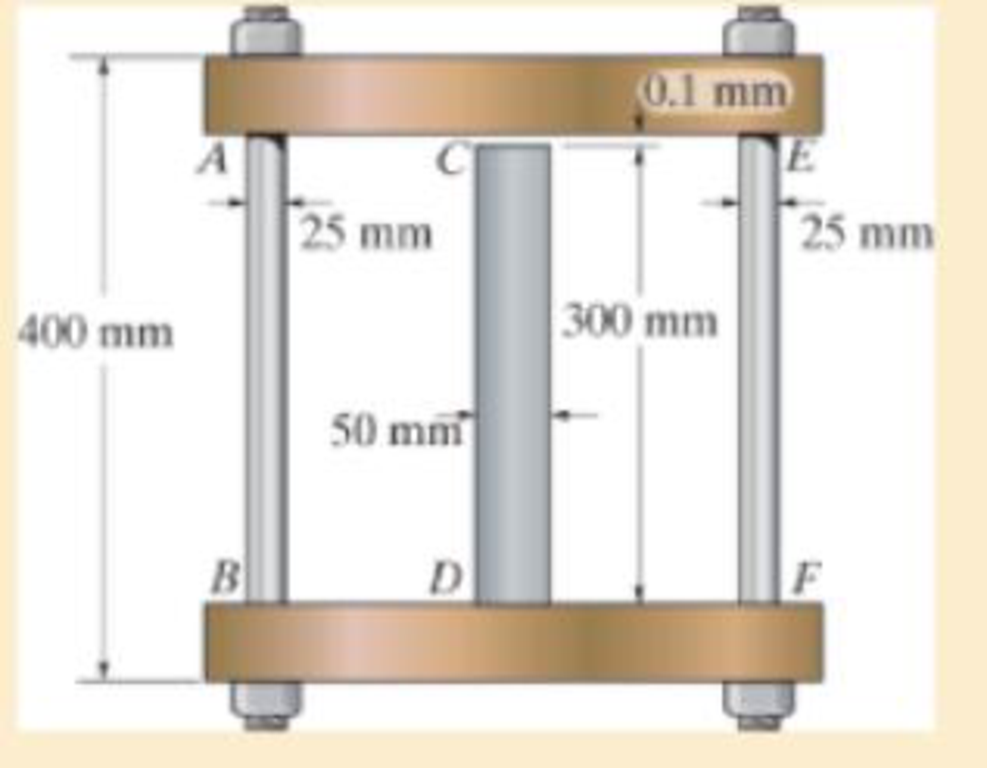

The assembly consists of two A992 steel bolts AB and EF and an 6061-T6 aluminum rod CD. When the temperature is at 30° C, the gap between the rod and rigid member AE is 0.1 mm Determine the normal stress developed in the bolts and the rod if the temperature rises to 130° C.

Assume BF is also rigid.

R4–1/2

The normal stress developed in the bolts and rod.

Answer to Problem 4.1RP

The normal stress developed in the bolts and rod are

Explanation of Solution

Given information:

The two bolts AB and EF are made of A992 steel.

The rod CD is made of 6061-T6 aluminum.

The Young’s modulus of the steel is

The Young’s modulus of the aluminum

The coefficient of thermal expansion of the steel

The coefficient of thermal expansion of the aluminum

The initial temperature

The finial temperature

The gap between the rod and rigid member AE is

The diameter of the bolts AB and EF

The diameter of the rod CD

The length of the bolts AB and EF

The length of the rod CD

Calculation:

Calculate the area of the bolts AB and EF

Substitute

Calculate the area of the rod CD

Substitute

Calculate the difference of temperature

Substitute

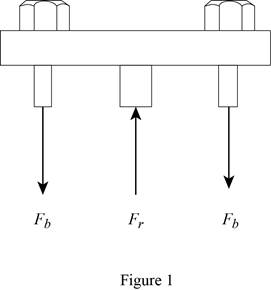

Show the free body diagram of the rigid cap as in Figure 1.

Refer Figure 1.

Calculate the vertical forces by applying the equation of equilibrium:

Sum of vertical forces is equal to 0.

Here,

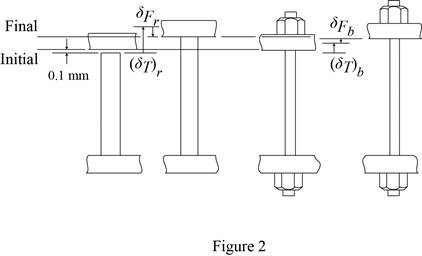

Show the initial and final position of the assembly as in Figure 2.

Refer Figure 2.

Here

The deformation is as follows:

Substitute

Calculate the force at the bolts AB and EF

Substitute

Calculate the force at the rod CD

Substitute

Calculate the normal stress developed in the bolts AB and EF

Substitute

Calculate the normal stress developed in the rod CD

Substitute

Hence, the normal stress developed in the bolts and rod are

Want to see more full solutions like this?

Chapter 4 Solutions

MECHANICS OF MATERIALS

Additional Engineering Textbook Solutions

Starting Out with Programming Logic and Design (5th Edition) (What's New in Computer Science)

Starting Out with Java: From Control Structures through Objects (7th Edition) (What's New in Computer Science)

Thermodynamics: An Engineering Approach

Starting Out with C++ from Control Structures to Objects (9th Edition)

Starting Out with Java: From Control Structures through Data Structures (4th Edition) (What's New in Computer Science)

Java: An Introduction to Problem Solving and Programming (8th Edition)

- My ID#016948724 please solve this problems and show me every step clear to follow pleasearrow_forwardMy ID# 016948724arrow_forwardPlease do not use any AI tools to solve this question. I need a fully manual, step-by-step solution with clear explanations, as if it were done by a human tutor. No AI-generated responses, please.arrow_forward

- Please do not use any AI tools to solve this question. I need a fully manual, step-by-step solution with clear explanations, as if it were done by a human tutor. No AI-generated responses, please.arrow_forwardPlease do not use any AI tools to solve this question. I need a fully manual, step-by-step solution with clear explanations, as if it were done by a human tutor. No AI-generated responses, please.arrow_forward[Q2]: The cost information supplied by the cost accountant is as follows:Sales 20,00 units, $ 10 per unitCalculate the (a/ newsale guantity and (b) new selling price to earn the sameVariable cost $ 6 per unit, Fixed Cost $ 30,000, Profit $ 50,000profit ifi) Variable cost increases by $ 2 per unitil) Fixed cost increase by $ 10,000Ili) Variable cost increase by $ 1 per unit and fixed cost reduces by $ 10,000arrow_forward

- can you please help me perform Visual Inspection and Fractography of the attatched image: Preliminary examination to identify the fracture origin, suspected fatigue striation, and corrosion evidences.arrow_forwardcan you please help[ me conduct Causal Analysis (FTA) on the scenario attatched: FTA diagram which is a fault tree analysis diagram will be used to gain an overview of the entire path of failure from root cause to the top event (i.e., the swing’s detachment) and to identify interactions between misuse, material decay and inspection errors.arrow_forwardhi can you please help me in finding the stress intensity factor using a k-calcluator for the scenario attathced in the images.arrow_forward

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY