EBK MATERIALS FOR CIVIL AND CONSTRUCTIO

4th Edition

ISBN: 8220102719569

Author: ZANIEWSKI

Publisher: PEARSON

expand_more

expand_more

format_list_bulleted

Textbook Question

Chapter 3, Problem 3.34QP

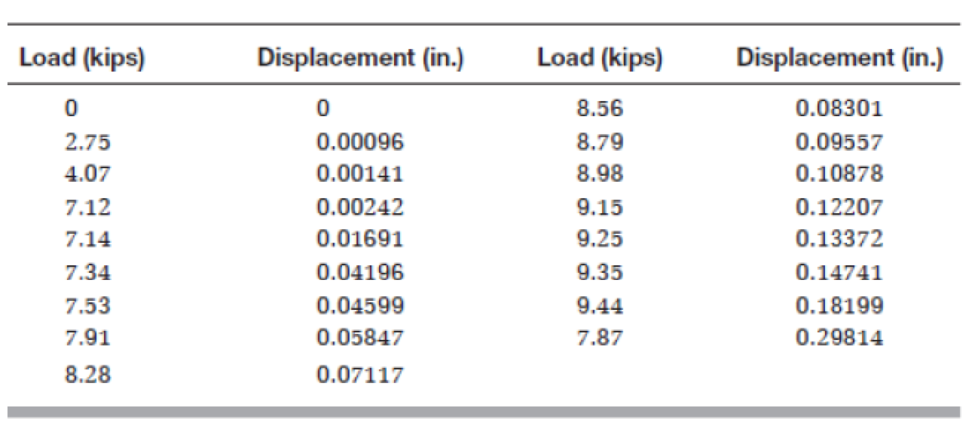

A grade 36 round steel bar with a diameter of 0.5 in. and a gauge length of 2 in. was subjected to tension to rupture following ASTM E-8 test procedure, The load and deformation data were as shown in Table P3.34.

Using a spreadsheet program obtain the Following:

- a. A plot of the stress-strain relationship. Label the axes and show units.

- b. A plot of the linear portion of the stress-strain relationship. Determine modulus of elasticity using the best fit approach.

- c. Proportional limit.

- d. Yield stress.

- e. Ultimate strength.

- f. When the applied load was 4.07 kips, the diameter was measured as 0.499905 in. Determine Poisson’s ratio.

- g. After the rod was broken, the two parts were put together and the diameter at the neck was measured as 0.416012 in. What is the true stress value at fracture? Is the true stress at fracture larger or smaller than the engineering stress at fracture? Why?

- h. Do you expect the true strain at fracture to be larger or smaller than the engineering strain at fracture? Why?

TABLE P3.34

Expert Solution & Answer

Want to see the full answer?

Check out a sample textbook solution

Students have asked these similar questions

3k

a

5

I

IKLF

d

25

5'

S'

E=29000ksi

I = 400 in 4

Ex = ?

Q = ?

A simply supported rectangular RC beam is to carry a uniform factored dead load of 1.2 kip/ft

and a concentrated factored live load of 16 kip at mid-span. The beam self-weight is not included

in these loads. The concrete weighs 135 pcf. The span length is 25 ft. Please find the smallest

section allowed by ACI and design accordingly. Use f c’ = 5,000 psi, f y = 75,000 psi. The

exposure is interior with no weather exposure.

a. Assume an arbitrary self-weight/ft of the beam.

b. Find the maximum factored bending moment in the beam.

c. Set up the moment equation and solve for the beam section.

d. Revise the assumption if needed

Ideal gas

Problems

3-1 The molecular weight of carbon dioxide, CO2, is 44. In an experiment the value y for

CO2 was found to be 1.3. Assuming that CO2 is a perfect gas, calculate the gas

constant, R, and the specific heats at constant pressure and constant volume, Cp, Cv

(0.189 kJ/kg.K; 0.63kJ/kg.K; 0.819kJ/kg.K)

3-2 Oxygen, O2, at 200 bar is to be stored in a steel vessel at 20°C the capacity of the vessel

is 0.04m³. Assuming that O₂ is a perfect gas, calculate the mass of oxygen that can be

stored in the vessel. The vessel is protected against excessive pressure by a fusible plug

which will melt if the temperature rises too high. At what temperature must the plug

melt to limit the pressure in the vessel to 240bar? The molecular weight of oxygen is 32

(10.5 kg; 78.6°C)

3-3 A quantity of a certain perfect gas is compressed from an initial state of 0.085m³, 1 bar

to a final state of 0.034m³, 3.9 bar. The specific heats at constant volume are 0.724

kJ/kg.K, and the specific heats at…

Chapter 3 Solutions

EBK MATERIALS FOR CIVIL AND CONSTRUCTIO

Ch. 3 - What is the chemical composition of steel? What is...Ch. 3 - Why does the ironcarbon phase diagram go only to...Ch. 3 - Draw a simple ironcarbon phase diagram showing the...Ch. 3 - What is the typical maximum percent of carbon in...Ch. 3 - Calculate the amounts and compositions of phases...Ch. 3 - Briefly discuss four heat treatment methods to...Ch. 3 - Define alloy steels. Explain why alloys are added...Ch. 3 - Prob. 3.8QPCh. 3 - Specifically state the shape and size of the...Ch. 3 - What are the typical uses of structural steel?

Ch. 3 - What is the range of thicknesses of cold-formed...Ch. 3 - Why is coil steel used for cold-formed steel...Ch. 3 - If a steel with a 33 ksi yield strength is used...Ch. 3 - Why is reinforcing steel used in concrete? Discuss...Ch. 3 - What is high-performance steel? State two HPS...Ch. 3 - Name three mechanical tests used to measure...Ch. 3 - The following laboratory tests are performed on...Ch. 3 - Sketch the stress-strain behavior of steel, and...Ch. 3 - Three steel bars with a diameter of 25 mm and...Ch. 3 - Three steel bars with a diameter of 0.5 in. and...Ch. 3 - Draw a typical stressstrain relationship for steel...Ch. 3 - Getting measurements from Figure 3.18, determine...Ch. 3 - A steel specimen is tested in tension. The...Ch. 3 - A steel specimen is tested in tension. The...Ch. 3 - A No. 10 steel rebar is tested in tension. By...Ch. 3 - A mild steel specimen originally 300 mm long is...Ch. 3 - A tension stress of 70 ksi was applied on a 12-in....Ch. 3 - A tensile stress is applied along the long axis of...Ch. 3 - A cylindrical steel alloy rod with a 0.5 in....Ch. 3 - A round steel alloy bar with a diameter of 0.75...Ch. 3 - A 19-mm reinforcing steel bar and a gauge length...Ch. 3 - Testing a round steel alloy bar with a diameter of...Ch. 3 - During the tension test on a steel rod within the...Ch. 3 - A grade 36 round steel bar with a diameter of 0.5...Ch. 3 - A high-yield-strength alloy steel bar with a...Ch. 3 - Estimate the cross-sectional area of a 350S125-27...Ch. 3 - An ASTM A615 grade 60 number 10 rebar with a gauge...Ch. 3 - A 32-mm rebar with a gauge length of 200 mm was...Ch. 3 - A steel pipe having a length of 3 ft. an outside...Ch. 3 - A steel pipe having a length of 1 m, an outside...Ch. 3 - A drill rod with a diameter of 10 mm is made of...Ch. 3 - A drill rod with, a diameter of 1/2 in. is made of...Ch. 3 - Prob. 3.43QPCh. 3 - An engineering technician performed a tension test...Ch. 3 - A Charpy V Notch (CVN) test was performed on a...Ch. 3 - Prob. 3.46QPCh. 3 - Prob. 3.47QPCh. 3 - How can the flaws in steel and welds be detected?...Ch. 3 - Determine the welding zone classification of A36...Ch. 3 - Briefly define steel corrosion. What are the four...Ch. 3 - Discuss the main methods used to protect steel...

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, civil-engineering and related others by exploring similar questions and additional content below.Similar questions

- A trapezoidal combined footing 5.5 m long is to supporttwo 400 mm square columns 5 meters apart. The center ofthe columns are both 0.25m away from property lines. Theleft column carries 675 kN while the right column 825 kN.The allowable soil pressure is 126 kPa. Assume footing is0.5m thick with soil backfill 0.7m thick. Weight of concreteis 23.6 kN/m3 and of soil is 20.4 kN/m3. 1. Determine the required footing area.2. Find the width of the smaller end of the footing.3. Calculate the width of the larger end of the footing.Ans:15.01m2, 2m, 3.5m please show the solution. Answer is providedarrow_forwardH.W: Evaluate the integral 1. 1 1 }} 0 y x²exy dxdy 2. 1 ܐy 2 dxdyarrow_forwardGiven the following end areas for cut & fill, complete the eart calculation using a shrinkage of 10%. Then draw the M.H.D. and the longitudinal pro of the earthworks & find the following: a) Limit of Economic Haul (L.E.H.). b) Freehaul volume (F.H.V.). c) Overhaul volume (O.H.V.). d) Waste volume. e) Borrow volume. f) Total cost of the earthworks. Given that: -Cost of overhaul = 30 ID/m².station. -Cost of borrow-120 ID/m³. - Cost of freehaul - 70 ID/m². -Freehaul Distance (F.H.D.)- 200m-2 stations. Areas (m²) Station Volumes (m) Cut Fill Cut+ Fill- 0 10 Corrected Fill- 1100 1 12 1300 2 14 1500 3 146 1500 14 350 550 250 275 10 5 16 96 1300 1430 6 1500 1650 14 7 1300 1430 12 S . 1000 1100 8 9 300 200 220 12 10 1400 16 11arrow_forward

- Calculate the clean bed head loss for a filter consisting of uniformly graded sphere silica beads (shape factor p = 1), all having a diameter of 1 mm, packed into a 5 m x 5 m filter bed with depth D = 8 m, with a bed porosity of ε = 0.4, treating a flow rate of 0.025 m³/s. Assume a viscosity of 1.25x10-6 m2/s. Report your answer with the units of meters and round to the nearest 0.1.arrow_forwardUsing the book Olin's Construction: Principles, Materials, and Methods By H. Leslie SimmonsUsing Materials for a Small Residential House Compile A detailed list of every single material used in the construction of this small Residential Home. Your list will be broken up into 5 stages FOUNDATION, FRAMING, ROUGH IN, ROOF, FINISH You do not need to estimate the quantity of materials. Choose the exterior and interior finishes. Find 3 SDS sheets for materialsfor each stage of the build . REMEMBER EVERY ITEM MISSED IN AN ESTIMATE WILL COST YOU MONEY. HOUSE DETAILS • Slab foundation • UTILITIES AND GROUND WORK IS COMPLETED . • Single Story • Copper plumbing or PEX 2x6 Wood Framing Gas Water Heater Gas appliances ROOF: asphalt shingles , Stick framing, Cross hipped roof House has Heating and A/C EXAMPLE: FOUNDATION Concrete Wood For formsarrow_forwardA1.4- Determine the factored moment resistance for the flanged beam (simply supported) shown in Figure 4. Given: Beam span L = 8m fc = 25MPa fy=400MPa As = 3-35M *350* mm 1.5 m Figure 4 *350* mm -60mmarrow_forward

- A2.3- a simply supported reinforced concrete beam of rectangular cross-section is shown in Figure 3. The beam supports a uniform dead load of 20 kN/m (excluding the beam self-weight) and a uniform live load of 20 kN/m. The beam width is restricted to 400 mm. The maximum aggregate size is 20 mm. We are using 10M bars for stirrups and 25M bars for tension steel. Concrete is type N with f'c = 35 MPa and fy = 400 MPa. The beam needs to have 2hr fire rating. Design the beam for the given load, considering the reinforcement ratio p < 0.5 pb Figure 3 WDL = 20 kN/m WLL= 20 kN/m 8.0 marrow_forwardOlin's Construction: Principles, Materials, and Methods By H. Leslie Simmonsarrow_forwardThe L6 x 4 x 1/2 single angle shown has two rows of bolts. Each leg has one row (one line) of 5/8 in bolts in each leg as shown. Determine the net area (An). If needed, I attached the section properties from AISC manual for L6x4x1/2.arrow_forward

- 3. Determine the reactions at the supports for the frame shown in following. 36.5 kN/m 14.6 kN/m Hinge R = 10 m 10 m -10 marrow_forward# 4 F3 Existing Flocculation Basin Design Parameters at 22.5 MGD: A) # of Basins: 5 B) # of Stages per Basin: 2 c) Basin Dimensions: (30 ft. X 4 ft. X 15 ft.) D) Volume per Basin 10,800 cf (80,787 Gal) E) Total Flocculation Volume: 54,000 cf (406,920 Gal) F) Theoretical Unit Detention Time: 25.9 minutes G) Flow through Velocity (Q): 1.16 ft/min Deliverables: 1) Determine if the existing flocculation basins are sufficient to accommodate the projected future capacity. A) Current Capacity: 22.5 MGD B) Future Capacity: 34.5 MGD for 110,000 residents C) If not, determine the number of additional flocculation basins needed to accommodate the future capacity of 34.5 MGD. a) Ignore this bullet point 2) Specify the basic dimensions (length, width, water height, weir dimensions, etc.) of these additional flocculation basins. 3) Specify the design flow rate, detention time, and the flow-through velocity for each basin under the maximum future capacity of 34.5 MGD, assuming one of the basins is…arrow_forwardA1.4- Determine the factored moment resistance for the flanged beam (simply supported) shown in Figure 4. Given: Beam span L = 8m fc = 25MPa fy=400MPa As = 3-35M *350* mm 1.5 m Figure 4 *350* mm -60mmarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Steel Design (Activate Learning with these NEW ti...Civil EngineeringISBN:9781337094740Author:Segui, William T.Publisher:Cengage Learning

Steel Design (Activate Learning with these NEW ti...Civil EngineeringISBN:9781337094740Author:Segui, William T.Publisher:Cengage Learning Materials Science And Engineering PropertiesCivil EngineeringISBN:9781111988609Author:Charles GilmorePublisher:Cengage Learning

Materials Science And Engineering PropertiesCivil EngineeringISBN:9781111988609Author:Charles GilmorePublisher:Cengage Learning Construction Materials, Methods and Techniques (M...Civil EngineeringISBN:9781305086272Author:William P. Spence, Eva KultermannPublisher:Cengage Learning

Construction Materials, Methods and Techniques (M...Civil EngineeringISBN:9781305086272Author:William P. Spence, Eva KultermannPublisher:Cengage Learning Engineering Fundamentals: An Introduction to Engi...Civil EngineeringISBN:9781305084766Author:Saeed MoaveniPublisher:Cengage Learning

Engineering Fundamentals: An Introduction to Engi...Civil EngineeringISBN:9781305084766Author:Saeed MoaveniPublisher:Cengage Learning Architectural Drafting and Design (MindTap Course...Civil EngineeringISBN:9781285165738Author:Alan Jefferis, David A. Madsen, David P. MadsenPublisher:Cengage Learning

Architectural Drafting and Design (MindTap Course...Civil EngineeringISBN:9781285165738Author:Alan Jefferis, David A. Madsen, David P. MadsenPublisher:Cengage Learning Solid Waste EngineeringCivil EngineeringISBN:9781305635203Author:Worrell, William A.Publisher:Cengage Learning,

Solid Waste EngineeringCivil EngineeringISBN:9781305635203Author:Worrell, William A.Publisher:Cengage Learning,

Steel Design (Activate Learning with these NEW ti...

Civil Engineering

ISBN:9781337094740

Author:Segui, William T.

Publisher:Cengage Learning

Materials Science And Engineering Properties

Civil Engineering

ISBN:9781111988609

Author:Charles Gilmore

Publisher:Cengage Learning

Construction Materials, Methods and Techniques (M...

Civil Engineering

ISBN:9781305086272

Author:William P. Spence, Eva Kultermann

Publisher:Cengage Learning

Engineering Fundamentals: An Introduction to Engi...

Civil Engineering

ISBN:9781305084766

Author:Saeed Moaveni

Publisher:Cengage Learning

Architectural Drafting and Design (MindTap Course...

Civil Engineering

ISBN:9781285165738

Author:Alan Jefferis, David A. Madsen, David P. Madsen

Publisher:Cengage Learning

Solid Waste Engineering

Civil Engineering

ISBN:9781305635203

Author:Worrell, William A.

Publisher:Cengage Learning,

Material Properties 101; Author: Real Engineering;https://www.youtube.com/watch?v=BHZALtqAjeM;License: Standard YouTube License, CC-BY