Concept explainers

M&L MANUFACTURING

M&L Manufacturing makes various components for printers and copiers. In addition to supplying these items to a major manufacturer, the company distributes these and similar items to office supply stores and computer stores as replacement parts for printers and desktop copiers in all the company makes about 20 different items. The two markets (the major manufacturer and the replacement market) require somewhat different handling. For example replacement products must be packaged individually whereas products are shipped in bulk to the major manufacturer.

The company does not use forecasts for production planning. Instead, the operations manager decides which items to produce and the batch size based on orders and the amounts in inventory. The products that have the fewest amounts in inventory get the highest priority. Demand is uneven, and the company has experienced being overstocked on some items and out of others. Being understocked has occasionally created tensions with the managers of retail outlets. Another problem is that prices of raw materials have been creeping up, although the operations manager thinks that this might be a temporary condition.

Because of competitive pressures and falling profits the manager has decide to undertake a number of changes. One change is to introduce more formal

With that m mind the manager wants to begin forecasting for two products. These products are important for several reasons. First, they account for a disproportionately large share of the company’s profits. Second, the manager believes that one of these products will become increasingly important to future growth plans and third, the other product has experienced periodic out-of-stock instances.

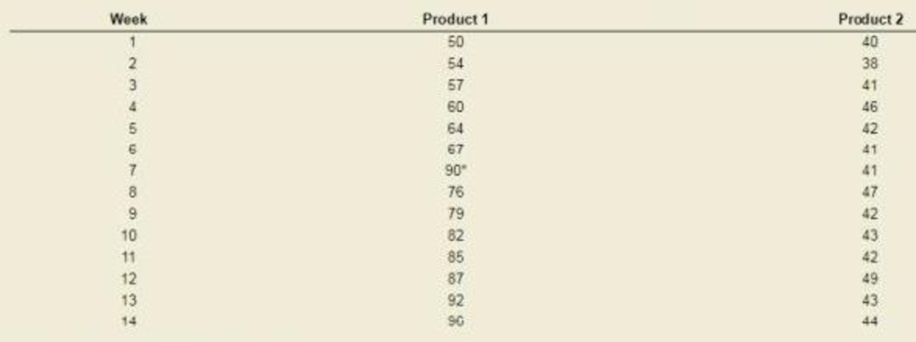

The manager has compiled data on product demand for the two products from order records for the previous 14 weeks. These are shown in the following table.

*Unusual order due to flooding of customer’s warehouse.

1. What are some of the potential benefits of a more formalitzed approach to forecasting?

Want to see the full answer?

Check out a sample textbook solution

Chapter 3 Solutions

EBK OPERATIONS MANAGEMENT

- Read Himachal Fertilizer Corporation (B) and critique the decision he actually made after reading Part B. Was your recommendation similar to what Neil did...how was it the same or how did it differ? Explain why with details from course materials and the case.arrow_forwardName the key stakeholders in the Himachal Fertilizer Corporation Part A case. Consider the stakeholder map in the image below. Which stakeholders would be the most important under your default lens?arrow_forwardThis crosstab shows product sub-category sales within categories, broken out by sales quarter. The quarterly values for each sub-category increase within each category, with the largest value at the bottom. Using Running Total as the calculation type, which scope and direction option gives this result?arrow_forward

- 6:35 nvas.liberty.edu < 72% i You must post before seeing replies. Edit history will be available to instructors. ☑ Due Feb 13 33 Replies (33) 50 points Discussion Thread: How to Look at the Bible After reading the assigned chapters in Everyday Bible Study (Chapters 1-5), create a learning log that lists 10 quotes from the assigned reading that highlight either a concept that resonated with you or a concept that represents new learning for you. Following each of these quotes, you must provide a 3-5 sentence explanation of how the selected quote represents either what resonated with you or this new learning. For an example of this type of thread, please see the provided example. Pleas ◄ Previous cussion Assignment instructions ✓ and the ||| Next ▸arrow_forwardDo a report to promote an innovative product/service within an organization of your choice. In your assignment, you need to focus on the below: 1. Give a brief introduction of the innovative product/service you are thinking about within an organization of your choice. 2. Analyze how you are going to promote your idea internally to your colleagues (e.g. meetings, presenting and disseminating the information). 3. Explain how you are going to convince them that this product/service is applicable and that it will create a competitive advantage in the market. 4. Refer to a similar product/service that your competitors have and analyze how the competitors’ product can be considered as a threat to your new product/service. 5. Estimate how much will the whole procedure cost to the business. 6. In your conclusions, describe how the new product/service will influence the whole organization’s environment. 3000 words and include and introducion, conclusion and references.arrow_forwardFor my learning and not a assignment question: Tesla, the U.S. electric vehicle manufacturer, has recently proposed to join Indonesia’s initiative to develop an EV battery supply chain within the country. This information was shared by a senior Indonesian government official, who noted that the government received Tesla's proposal on Thursday. Indonesia, known for its rich nickel reserves, is already in discussions with companies like China's Contemporary Amperex Technology (CATL) and South Korea's LG Chem to establish a comprehensive EV battery supply chain that covers everything from raw materials to the final product. Sepian Hari Seto, the deputy for investment and mining at the Coordinating Ministry of Maritime Affairs and Investment, expressed enthusiasm for Tesla's advanced lithium battery technology. He conveyed that the collaboration with Tesla, along with CATL and LG, presents a valuable opportunity for technology transfer and learning. Furthermore, Seto mentioned the…arrow_forward

- Your company is considering investing in a Human Resource Information System (HRIS).Briefly explain the strategies for justifying HRIS investments.arrow_forwardPresent the criteria you would utilize to determine if a right should be extended to an employee or if it would unnecessarily impact a manager’s ability to manage. Additionally, assess how you would balance the need for management rights against the need for employee rights, and how greater employee rights positively and negatively affect the future of the organization.arrow_forwardprovide schoarly research and references as to how internal and exteral audit is a risk management strategy to mitigate risk in a financial institutionarrow_forward

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,- MarketingMarketingISBN:9780357033791Author:Pride, William MPublisher:South Western Educational Publishing

Contemporary MarketingMarketingISBN:9780357033777Author:Louis E. Boone, David L. KurtzPublisher:Cengage Learning

Contemporary MarketingMarketingISBN:9780357033777Author:Louis E. Boone, David L. KurtzPublisher:Cengage Learning