Concept explainers

Case summary:

Person PH, the

To develop: A better schedule by reducing the number of orders and carrying some amount of inventory and identify the cost savings with the new schedule.

Explanation of Solution

Given information:

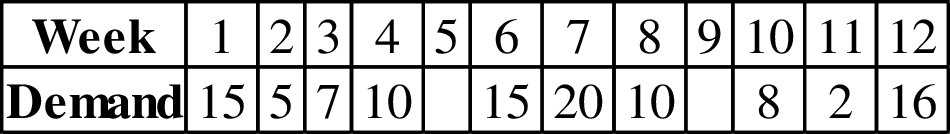

Model 1000 Master Schedule

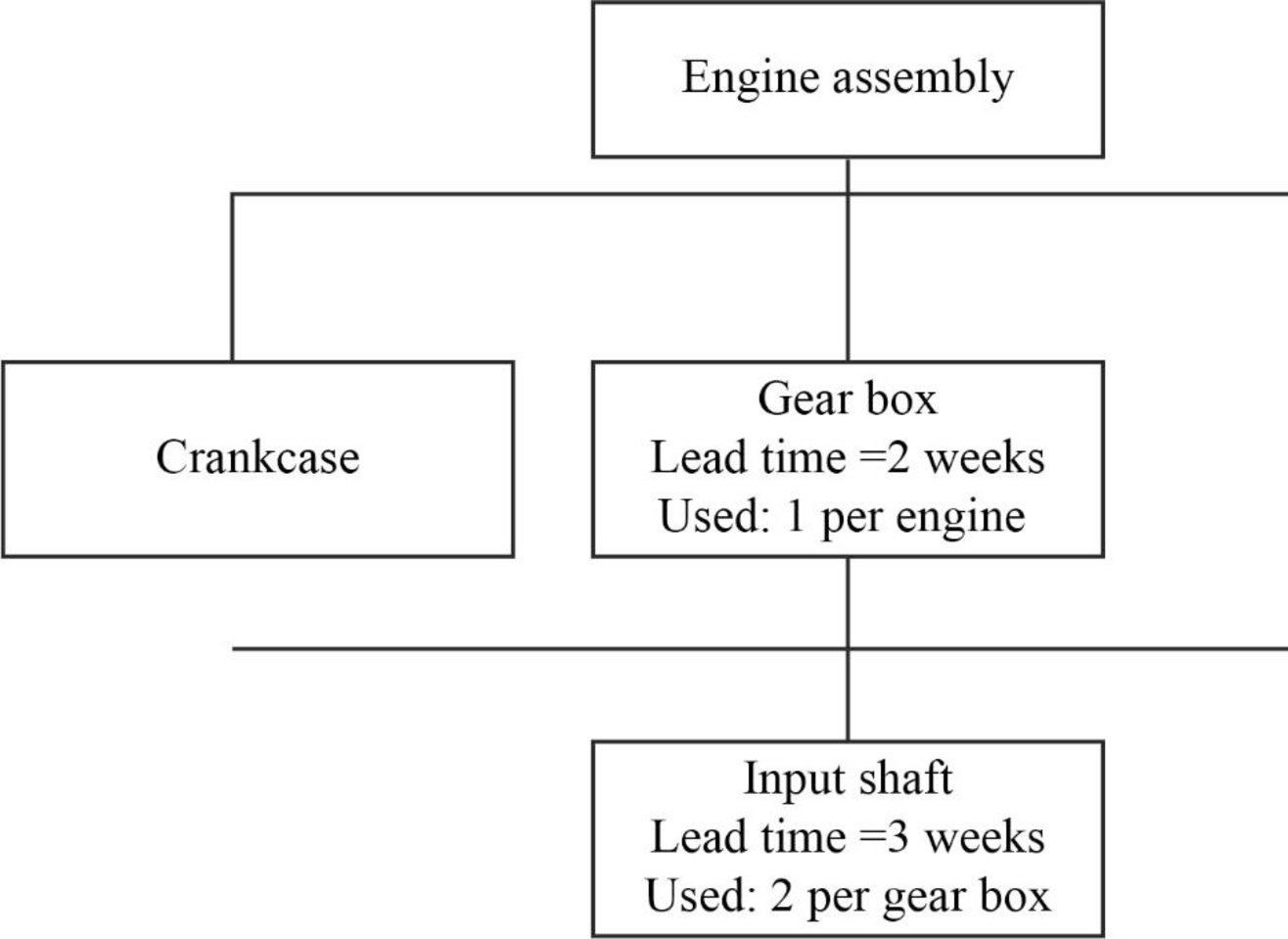

Model 1000 Product Structure

- There are 17 gearboxes on-hand at the beginning of week 1. 5 gearboxes are on order and should be delivered at the beginning of week 2.

- There are 40 input shafts present on-hand at the beginning of week 1, and 22 are scheduled to be delivered at the beginning of week 2.

Cost:

Gearbox:

Setup cost (S) = $90 per order.

Inventory carrying cost (I) = $2 per unit per week.

Input shaft:

Setup cost (S) = $45 per order.

Inventory carrying cost (I) = $1 per unit per week.

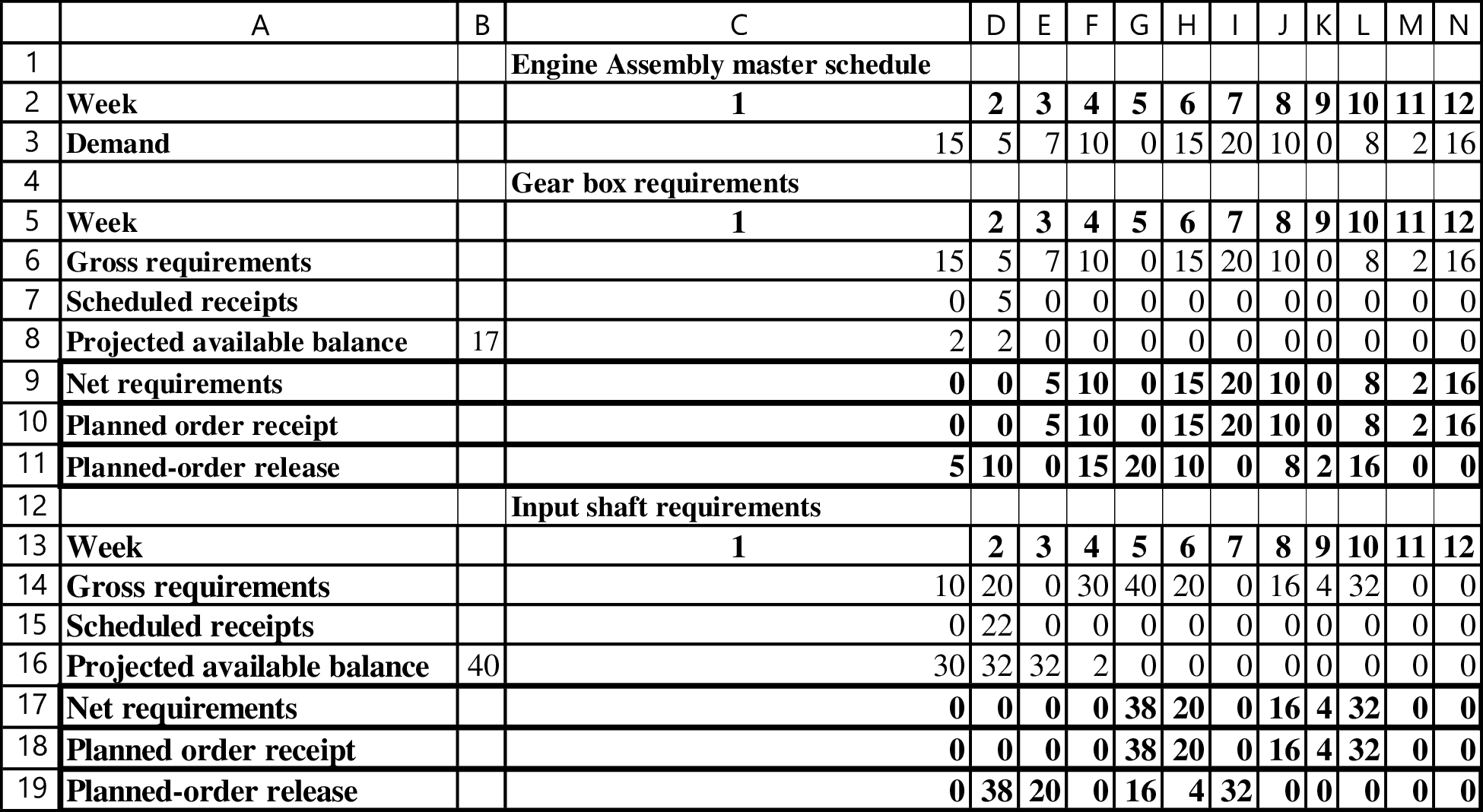

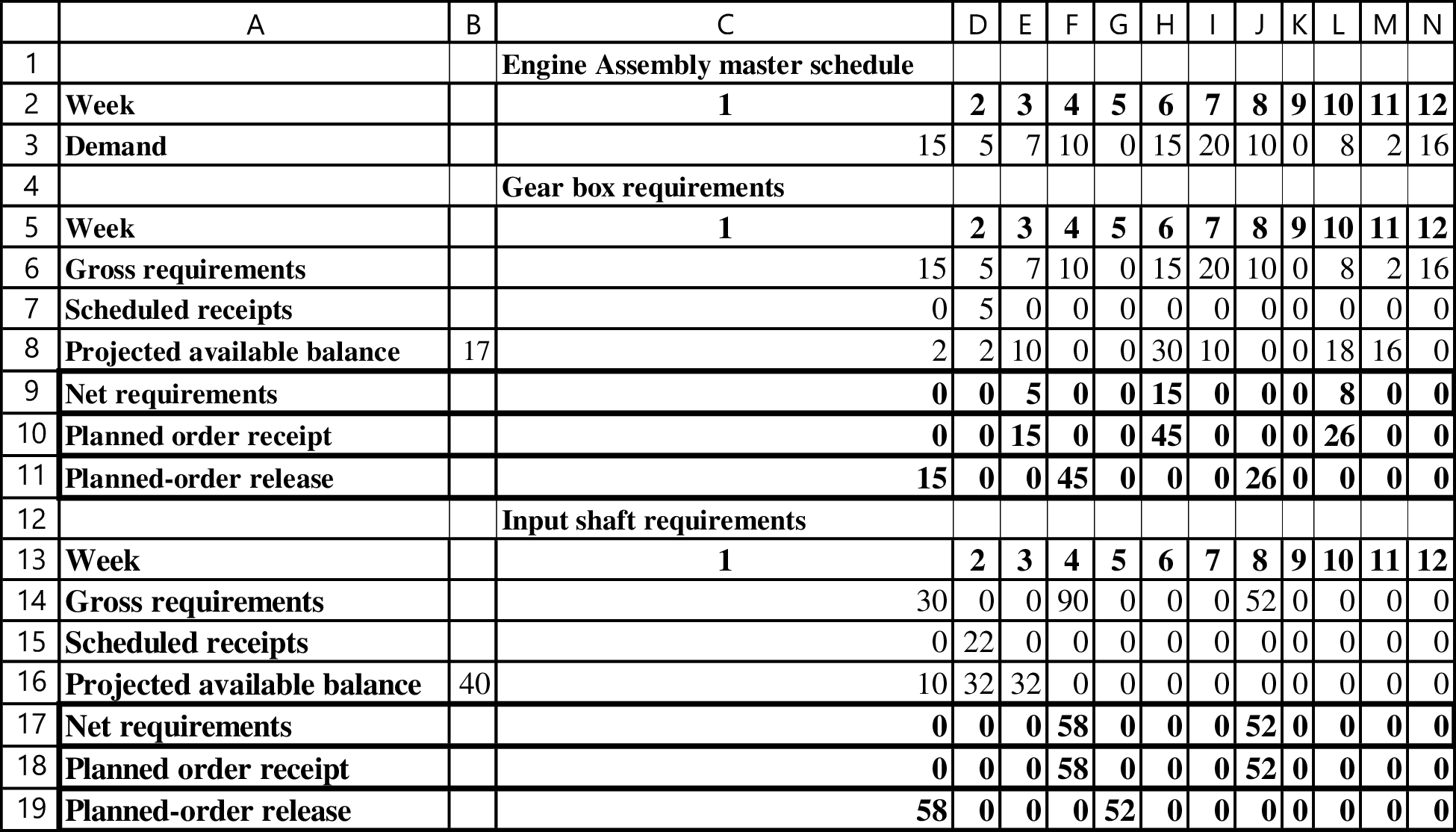

Existing schedule:

Each gearbox will require two units of the input shaft. Hence, the planned order release of the gearbox is doubled when they become the gross requirements of the input shaft.

Calculation of cost of the schedule:

Gearbox:

There are 8 planned order releases. The inventory is 2 units in week 1 and 2 units in week 2. Therefore, the total cost would be:

Input shaft:

There are 5 planned order releases. The inventory is 30 units in week 1, 32 units in week 2, 32 units in week 3, and 2 units in week 4. Therefore, the total cost would be:

The total cost of the schedule would be:

The cost of the existing schedule is $1,049.

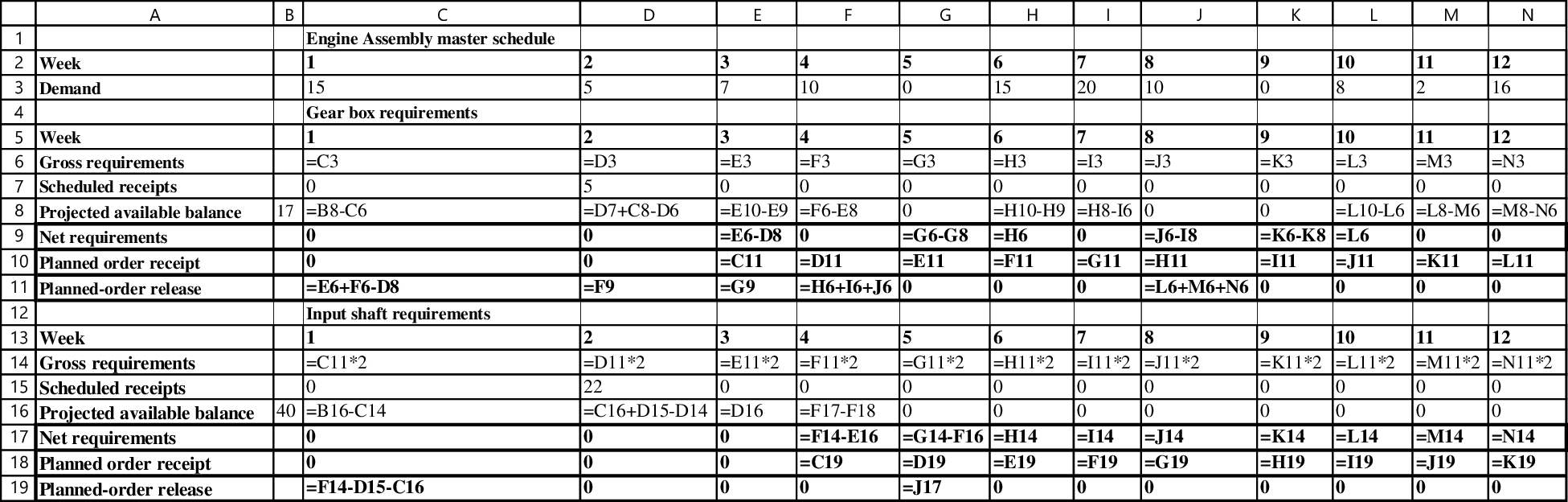

Calculation of net requirements and planned order release for the new schedule:

In order to reduce the number of orders, the planned order releases of three weeks are combined together and released with a lead time of 2 weeks while carrying some amount of inventory.

Formula:

Calculation of cost of the schedule:

Gearbox:

There are 3 planned order releases. The inventory is 2 units in week 1, 2 units in week 2, 10 units in week 3, 30 units in week 6, 10 units in week 7, 18 units in week 11, and 16 units in week 12. Therefore, the total cost would be:

Input shaft:

There are 2 planned order releases. The inventory is 10 units in week 1, 32 units in week 2, and 32 units in week 3. Therefore, the total cost would be:

The total cost of the schedule would be:

The cost of the new schedule is $610.

Calculation the cost difference between the two schedules:

The cost savings with the new schedule is $439.

Want to see more full solutions like this?

Chapter 21 Solutions

Operations and Supply Chain Management

- Gas sales across type: 80% of gas sales tend to be regular. 15% midgrade, 5% tend to be premium. $0.10 increase in price per gallon tends to decrease gallons sold by 1 to 3%. Jan-0.87, Feb-0.95, Mar-1.00, Apr-1.05, May-1.08, Jun1.15, Jul-1.13, Aug-1.07, Sep-1.02, Oct-0.94, Nov-0.89, Dec-0.85. You want the MAPE to be below 20%, if ypu can get it to or below 10% they'll throw in extra $10k. Wont get bonus if it is above 11% or 20%. It cannot be over 20%.arrow_forwardhelp me choose the correct path please. There are other optionsarrow_forwardNegotiators can gain several benefits from using the strategy of multiple equivalent simultaneous offers. By offering multiple options it reduces the chance of rejection. It also improves the chances of reaching reaching an agreement. By presenting multiple offers, it shows you are flexible. agree with the postarrow_forward

- Negotiators can gain several benefits from using the strategy of multiple equivalent simultaneous offers. By offering multiple options it reduces the chance of rejection. It also improves the chances of reaching reaching an agreement. By presenting multiple offers, it shows you are flexible. disagree with this post or add on to the postarrow_forwardThe strategy of Multiple Equivalent Simultaneous Offers involves presenting several equally valuable options to the other party during negotiations. This approach benefits negotiators by creating flexibility and increasing the chances of finding a mutually agreeable solution. By offering multiple options, negotiators show that they are open to compromise, which can build trust and make the negotiation process smoother. It also helps avoid getting stuck on one issue, as the other party can choose from several alternatives that meet their needs. In my experience, using MESOs in a work negotiation helped both parties reach an agreement more quickly because each option was carefully thought out to address different needs, and this made it easier for us to settle on one that worked for both sides. This strategy can also reveal what is most important to the other party, helping negotiators understand their priorities better. agree or disagree with the postarrow_forwardExamine the conflicts between improving customer service levels and controlling costs in sales. Strategies to Balance Both customer service levels and controlling costs in sales 1.Outsourcing and workforce optimization 2. AI-driven customer supportarrow_forward

- how can you gain trust in a negotiation setting?arrow_forward✓ Custom $€ .0 .on File Home Insert Share Page Layout Formulas Data Review View Help Draw Arial 10 B B14 ✓ X✓ fx 1400 > 甘く 曲 > 冠 > Comments Editing ✓ . . . P Q R S T 3 A Production cost ($/unit) B с D E F G H J K L M N $74.00 4 Inventory holding cost ($/unit) $1.50 5 Lost sales cost ($/unit) $82.00 6 Overtime cost ($/unit) $6.80 7 Undertime cost ($/unit) $3.20 8 Rate change cost ($/unit) $5.00 9 Normal production rate (units) 2,000 10 Ending inventory (previous Dec.) 800 11 Cumulative 12 13 Month Demand Cumulative Demand Product Production Availability Ending Inventory Lost Cumulative Cumulative Product Sales 14 January 1,400 1,475 15 FUERANZ222222223323333BRUINE 14 February 1,000 2,275 Month January February Demand Demand Production Availability Ending Inventory Lost Sales 1,400 #N/A 1,475 #N/A #N/A #N/A 1,000 #N/A 2,275 #N/A #N/A #N/A 16 March 1,800 2,275 March 1,800 #N/A 2,275 #N/A #N/A #N/A 17 April 2,700 2,275 April 2,700 #N/A 2,275 #N/A #N/A #N/A 18 May 3,000 2,275 May 3,000 #N/A…arrow_forwardFollow guidelines and summarize in a paragrapharrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education

Operations ManagementOperations ManagementISBN:9781259667473Author:William J StevensonPublisher:McGraw-Hill Education Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Operations and Supply Chain Management (Mcgraw-hi...Operations ManagementISBN:9781259666100Author:F. Robert Jacobs, Richard B ChasePublisher:McGraw-Hill Education

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.

Production and Operations Analysis, Seventh Editi...Operations ManagementISBN:9781478623069Author:Steven Nahmias, Tava Lennon OlsenPublisher:Waveland Press, Inc.