(a)

Interpretation:

The heat treatment for

Concept Introduction:

Material hardness is the property of a metal due to which material resist the plastic reformation. Plastic reformation means material reformation which undergoes non-reversible change. Hardness is the property of any material due to which it resist to bend, scratch or any other deformation. Hardness is not constant or fixed for all material, but it depends upon strength and plasticity of metal, material hardness is expressed in terms of hardness number.

Answer to Problem 13.16P

Heating to

Explanation of Solution

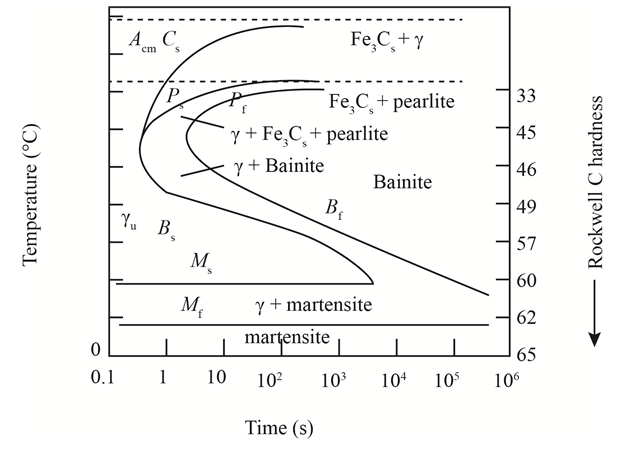

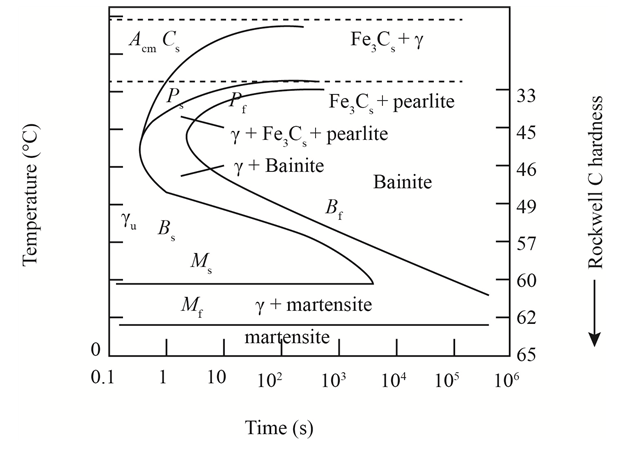

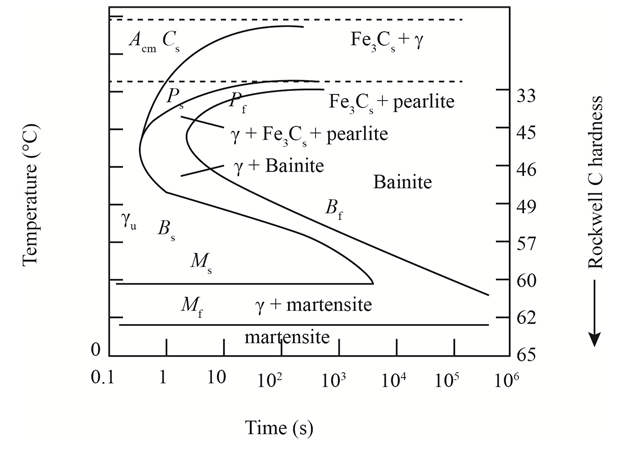

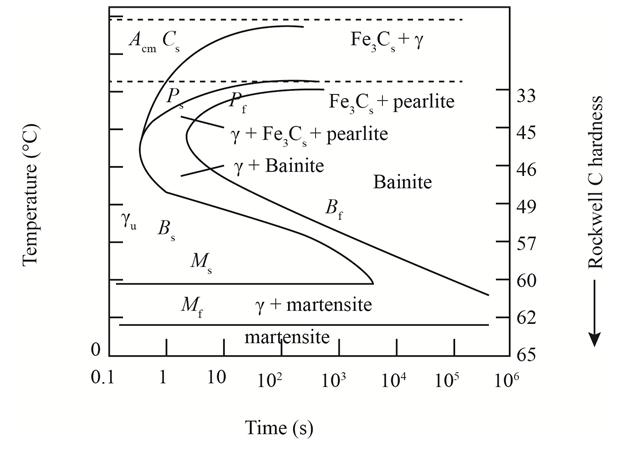

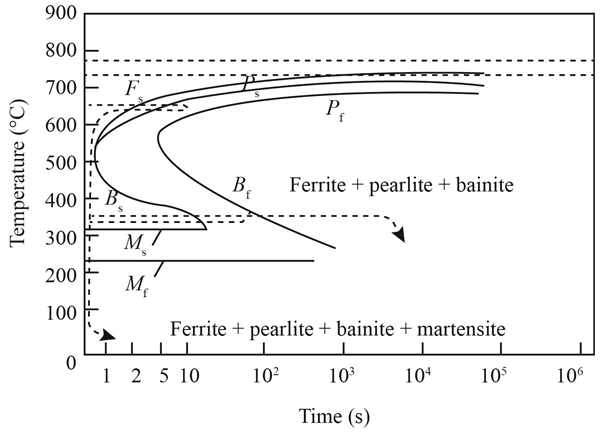

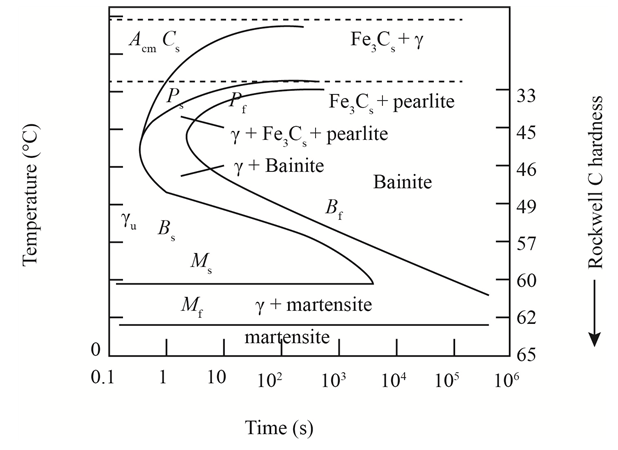

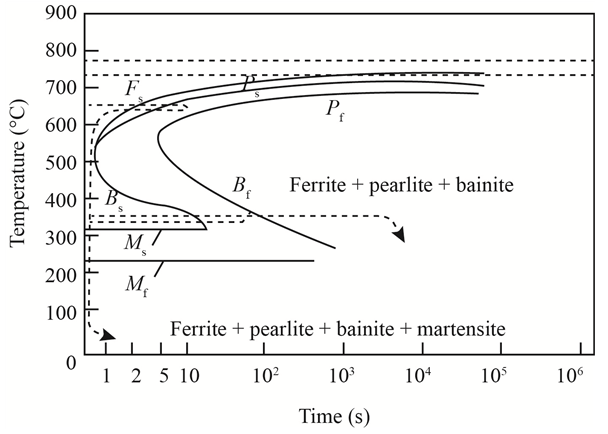

The given diagram is a TTT diagram which gases a relation between composition and temperature with time.

The given image shows temperature and time for ferrite, pearlite, bainite, and martensite following are the steps to obtain appropriate isothermal heat treatment.

For isothermally annealed

1) Step1: Heat the steel to

2) Step2: Quench it to

3) Step3: Quench again it to

(b)

Interpretation:

The heat treatment for

Concept Introduction:

Material hardness is the property of a metal due to which material resist the plastic reformation. Plastic reformation means material reformation which undergoes non-reversible change. Hardness is the property of any material due to which it resist to bend, scratch or any other deformation. Hardness is not constant or fixed for all material, but it depends upon strength and plasticity of metal, material hardness is expressed in terms of hardness number.

Answer to Problem 13.16P

Heating to

Explanation of Solution

The given diagram is a TTT diagram which gases a relation between composition and temperature with time.

The given image shows temperature and time for ferrite, pearlite, bainite, and martensite following are the steps to obtain appropriate isothermal heat treatment.

For isothermally annealed

1) Step1: Heat the steel to

2) Step2: Quench it to yy

3) Step3: Quench again it toyyy

(c)

Interpretation:

The heat treatment for yyyyy

Concept Introduction:

Material hardness is the property of a metal due to which material resist the plastic reformation. Plastic reformation means material reformation which undergoes non-reversible change. Hardness is the property of any material due to which it resist to bend, scratch or any other deformation. Hardness is not constant or fixed for all material, but it depends upon strength and plasticity of metal, material hardness is expressed in terms of hardness number.

Answer to Problem 13.16P

Heating to

Explanation of Solution

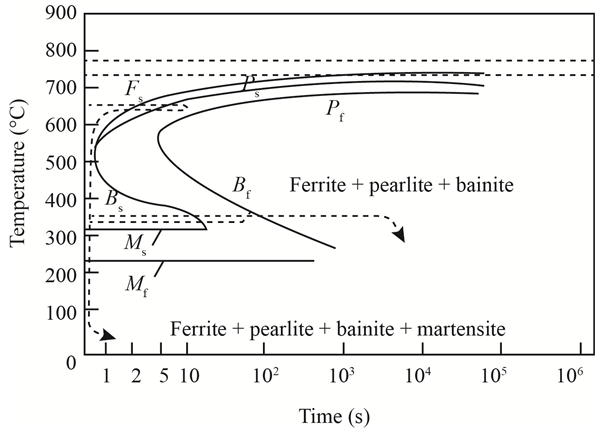

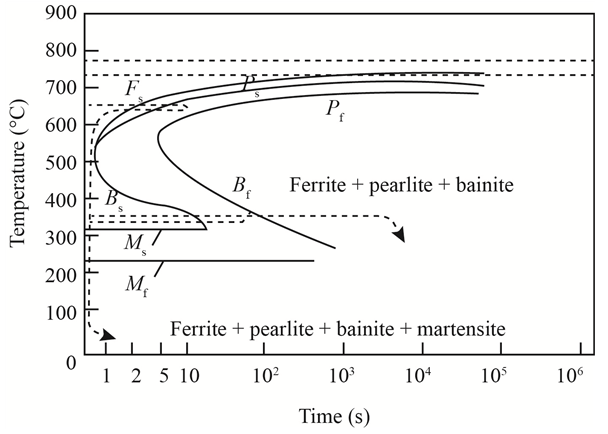

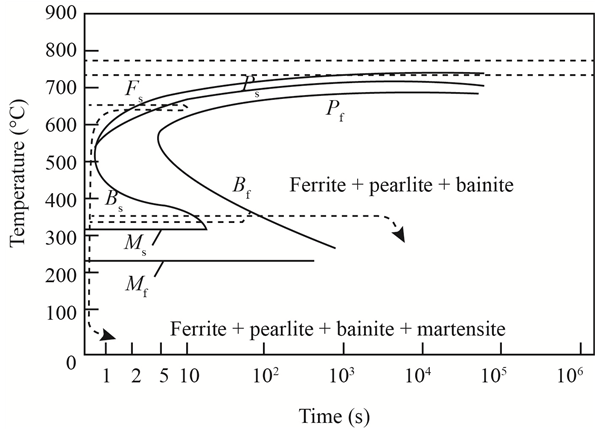

The given diagram is a TTT diagram which gases a relation between composition and temperature with time.

The given image shows temperature and time for ferrite, pearlite, bainite, and martensite following are the steps to obtain appropriate isothermal heat treatment.

For isothermally annealed

1) Step1: Heat the steel to

2) Step2: Quench it to

3) Step3: Quench again it to

(d)

Interpretation:

The heat treatment for

Concept Introduction:

Material hardness is the property of a metal due to which material resist the plastic reformation. Plastic reformation means material reformation which undergoes non-reversible change. Hardness is the property of any material due to which it resist to bend, scratch or any other deformation. Hardness is not constant or fixed for all material, but it depends upon strength and plasticity of metal, material hardness is expressed in terms of hardness number.

Answer to Problem 13.16P

Heating to

Explanation of Solution

The given diagram is a TTT diagram which gases a relation between composition and temperature with time.

The given image shows temperature and time for ferrite, pearlite, bainite, and martensite following are the steps to obtain appropriate isothermal heat treatment.

For isothermally annealed 1050 steel with HRC 40 is:-

1) Step1: Heat the steel to

2) Step2: Quench it to

3) Step3: Quench again it to

(e)

Interpretation:

The heat treatment for

Concept Introduction:

Material hardness is the property of a metal due to which material resist the plastic reformation. Plastic reformation means material reformation which undergoes non-reversible change. Hardness is the property of any material due to which it resist to bend, scratch or any other deformation. Hardness is not constant or fixed for all material, but it depends upon strength and plasticity of metal, material hardness is expressed in terms of hardness number.

Answer to Problem 13.16P

Heating to

Explanation of Solution

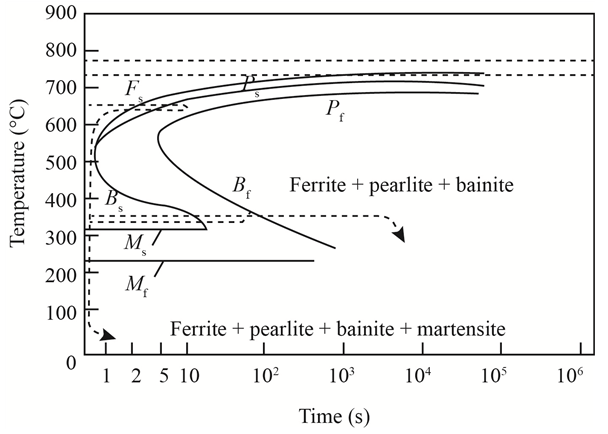

The given diagram is a TTT diagram which gases a relation between composition and temperature with time.

The given image shows temperature and time for ferrite, pearlite, bainite, and martensite following are the steps to obtain appropriate isothermal heat treatment.

For isothermally annealed 10110 steel with HRC 55is:-

1) Step1: Heat the steel to

2) Step2: Quench it to

3) Step3: Quench again it to

(f)

Interpretation:

The heat treatment for

Concept Introduction:

Material hardness is the property of a metal due to which material resist the plastic reformation. Plastic reformation means material reformation which undergoes non-reversible change. Hardness is the property of any material due to which it resist to bend, scratch or any other deformation. Hardness is not constant or fixed for all material, but it depends upon strength and plasticity of metal, material hardness is expressed in terms of hardness number.

Answer to Problem 13.16P

Heating to

Explanation of Solution

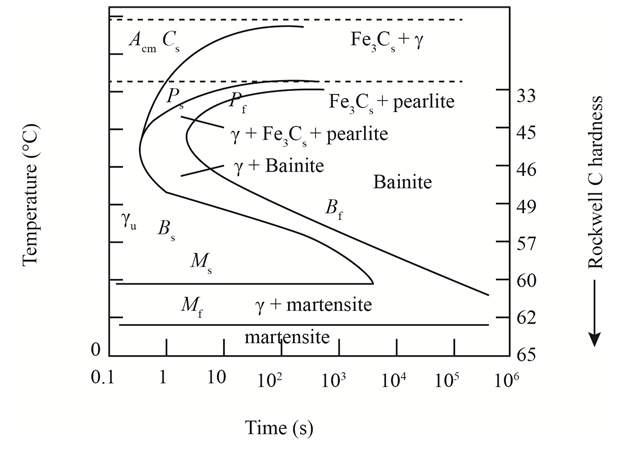

The given diagram is a TTT diagram which gases a relation between composition and temperature with time.

The given image shows temperature and time for ferrite, pearlite, bainite, and martensite following are the steps to obtain appropriate isothermal heat treatment.

For isothermally annealed

1) Step1: Heat the steel to

2) Step2: Quench it to

3) Step3: Quench again it to

Want to see more full solutions like this?

Chapter 13 Solutions

Essentials Of Materials Science And Engineering

- Given the following request to an AI chatbot, which response is better? Prompt Write a love poem about someone longing for a sandwich. Make it a sonnet, and give it a tone that straddles a serious love poem and whimsy appropriate for a poem about a sandwich.arrow_forwardHelp i keep getting the wrong answer. So I must be doing something wrong.arrow_forwardSuppose that a coin is tossed three so that the sample space is Let X represent the number of heads that can come up. i) Find the probability function corresponding to the random variable X. Assuming that the coin is fair ii) Find the distribution function for the random variable X. iii) Obtain its graph.arrow_forward

- Q9 A single-phase transformer, 2500 / 250 V, 50 kVA, 50 Hz has the following parameters, the Primary and secondary resistances are 0.8 ohm and 0.012 ohm respectively, the primary and secondary reactance are 4 ohm and 0.04 ohm respectively and the transformer gives 96% maximum efficiency at 75% full-load. The magnetizing component of-load current is 1.2 A on 2500 V side. 1- Draw the equivalent circuit referred to primary (H.V side) and inserts all the values in it 2- Find out Ammeter, voltmeter and wattmeter readings on open-circuit and short-circuit test. If supply is given to 2500 V side in both cases. Ans. O.C. Test (Vo= 2500 V, lo=1.24 A, Wo=781.25 w) S.C. Test (Vsc =164.924 V, Isc =20 A, Wsc =800 w )arrow_forwardQ. VI: An equimolar liquid mixture of benzene and toluene is separated into two product streams by distillation. At each point in the column some of the liquid vaporizes and some of the vapor stream condenses. The vapor leaving the top of the column, which contains 97 mole% benzene, is completely condensed and split into two equal fractions: one is taken off as the overhead product stream, and the other (the reflux) is recycled to the top of the column. The overhead product stream contains 89.2% of the benzene fed to the column. The liquid leaving the bottom of the column is fed to a partial reboiler in which 45% of it is vaporized. The vapor generated in the reboiler (the boilup) is recycled to become the rising vapor stream in the column, and the residual reboiler liquid is taken off as the bottom product stream. The compositions of the streams leaving the reboiler are governed by the relation, YB/(1 - YB) XB/(1 - XB) = 2.25 where YB and XB are the mole fractions of benzene in the…arrow_forward1. Comparison between Stack and Queue: Concepts and Use Cases A comparative study between stacks and queues in terms of behavior, structure, and real-world applications.arrow_forward

- Is developed App in play store much easier than in app store because i look app like human anonymus and like walter labs prioritize iphone app store first is it difficult to developed app on play store ? And btw i want to move to iphone anroid suckarrow_forwardBelow is a projection of the inertia ellipsoid in the b1-b2 plane (b1 and b2 are unit vectors). All points on the ellipsoid surface represent moments of inertia in various directions. The distance R is related to the distance D such that R = md. Determine m.arrow_forwardQ2-A)- Enumerate the various losses in transformer. Explain how each loss varies with (Load current, supply voltage). B)- Draw the pharos diagram at load on primary side.arrow_forward

- Q2- What are the parameters and loss that can be determined during open-circuit test of singlephase transformer. Draw the circuit diagram of open-circuit test and explain how can you calculate the Parameters and loss.arrow_forwardQ2-Drive the condition of maximum efficiency of single-phase transformer. Q1- A 5 KVA, 500/250 V ,50 Hz, single phase transformer gave the following reading: O.C. Test: 250 V,2 A, 50 W (H.V. side open) S.C. Test: 25 V10 A, 60 W (L.V. side shorted) Determine: i) The efficiency on full load, 0.8 lagging p.f. ii) Draw the equivalent circuit referred to primary and insert all the values it.arrow_forwardQ2- Describe various losses in transformer. Explain how each loss varies with load current, supply voltagearrow_forward

MATLAB: An Introduction with ApplicationsEngineeringISBN:9781119256830Author:Amos GilatPublisher:John Wiley & Sons Inc

MATLAB: An Introduction with ApplicationsEngineeringISBN:9781119256830Author:Amos GilatPublisher:John Wiley & Sons Inc Essentials Of Materials Science And EngineeringEngineeringISBN:9781337385497Author:WRIGHT, Wendelin J.Publisher:Cengage,

Essentials Of Materials Science And EngineeringEngineeringISBN:9781337385497Author:WRIGHT, Wendelin J.Publisher:Cengage, Industrial Motor ControlEngineeringISBN:9781133691808Author:Stephen HermanPublisher:Cengage Learning

Industrial Motor ControlEngineeringISBN:9781133691808Author:Stephen HermanPublisher:Cengage Learning Basics Of Engineering EconomyEngineeringISBN:9780073376356Author:Leland Blank, Anthony TarquinPublisher:MCGRAW-HILL HIGHER EDUCATION

Basics Of Engineering EconomyEngineeringISBN:9780073376356Author:Leland Blank, Anthony TarquinPublisher:MCGRAW-HILL HIGHER EDUCATION Structural Steel Design (6th Edition)EngineeringISBN:9780134589657Author:Jack C. McCormac, Stephen F. CsernakPublisher:PEARSON

Structural Steel Design (6th Edition)EngineeringISBN:9780134589657Author:Jack C. McCormac, Stephen F. CsernakPublisher:PEARSON Fundamentals of Materials Science and Engineering...EngineeringISBN:9781119175483Author:William D. Callister Jr., David G. RethwischPublisher:WILEY

Fundamentals of Materials Science and Engineering...EngineeringISBN:9781119175483Author:William D. Callister Jr., David G. RethwischPublisher:WILEY