EBK MANUFACTURING ENGINEERING & TECHNOL

7th Edition

ISBN: 9780100793439

Author: KALPAKJIAN

Publisher: YUZU

expand_more

expand_more

format_list_bulleted

Concept explainers

Textbook Question

Chapter 11, Problem 59SDP

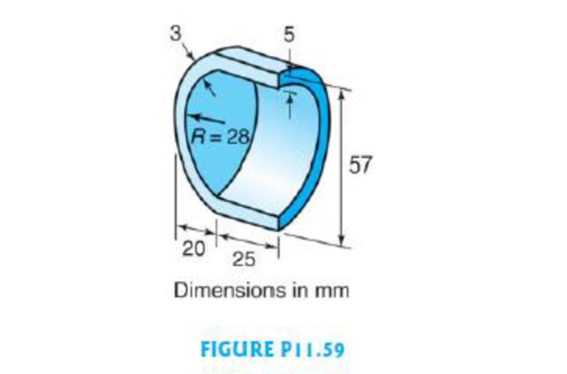

The part shown in Fig. P11.59 is a hemispherical shell used as an acetabular (mushroom-shaped) cup in a total hip replacement. Select a casting process for making this part, and provide a sketch of all the patterns or tooling needed if it is to be produced from a cobalt–chrome alloy.

Expert Solution & Answer

Want to see the full answer?

Check out a sample textbook solution

Students have asked these similar questions

(read image)

Qu. 13 What are the indices for the Direction 2 indicated by vector in the following sketch?

Qu. 14 Determine the indices for the direction A and B shown in the following cubic unit cell.

please show all work step by step from material engineering

The thin-walled open cross section shown is transmitting torque 7. The angle of twist ₁ per unit length of each leg can be

determined separately using the equation

01

=

3Ti

GLIC

3

where G is the shear modulus, ₁ is the angle of twist per unit length, T is torque, and L is the length of the median line.

In this case, i = 1, 2, 3, and T; represents the torque in leg i. Assuming that the angle of twist per unit length for each

leg is the same, show that

T= Lic³ and Tmaz = G01 Cmax

Consider a steel section with Tallow = 12.40 kpsi.

C1

2 mm

L1

20 mm

C2

3 mm

L2

30 mm

C3

2 mm

L3

25 mm

Determine the torque transmitted by each leg and the torque transmitted by the entire section.

The torque transmitted by the first leg is |

N-m.

The torque transmitted by the second leg is

N-m.

The torque transmitted by the third leg is

N-m.

The torque transmitted by the entire section is

N-m.

Chapter 11 Solutions

EBK MANUFACTURING ENGINEERING & TECHNOL

Ch. 11 - Describe the differences between expendable and...Ch. 11 - Name the important factors in selecting sand for...Ch. 11 - What are the major types of sand molds? What are...Ch. 11 - List important considerations when selecting...Ch. 11 - What is the function of a core?Ch. 11 - What is the difference between sand-mold and...Ch. 11 - What are composite molds? Why are they used?Ch. 11 - Describe the features of plaster-mold casting.Ch. 11 - Name the type of materials typically used for...Ch. 11 - What are the advantages of pressure casting over...

Ch. 11 - List the advantages and limitations of die...Ch. 11 - What is the purpose of a riser? What is a blind...Ch. 11 - Explain the purpose of a vent and a runner in a...Ch. 11 - How are shell molds produced?Ch. 11 - What keeps the mold together in vacuum casting?Ch. 11 - What is squeeze casting? What are its advantages?Ch. 11 - What are the advantages of the lost-foam casting...Ch. 11 - Prob. 18RQCh. 11 - What are the reasons for the large variety of...Ch. 11 - Why are risers not as useful in die casting as...Ch. 11 - Describe the drawbacks to having a riser that is...Ch. 11 - Why can blind risers be smaller than open-top...Ch. 11 - Why does die casting produce the smallest cast...Ch. 11 - Why is the investment-casting process capable of...Ch. 11 - What differences, if any, would you expect in the...Ch. 11 - Recently, cores for sand casting have been...Ch. 11 - Would you recommend preheating the molds used in...Ch. 11 - Give reasons for, and examples of, using die...Ch. 11 - Referring to Fig. 11.3, do you think it is...Ch. 11 - Explain why squeeze casting produces parts with...Ch. 11 - How are the individual wax patterns attached on a...Ch. 11 - Describe the measures that you would take to...Ch. 11 - You have seen that, even though die casting...Ch. 11 - How are hollow parts with various cavities made by...Ch. 11 - It was stated that the strength-to-weight ratio of...Ch. 11 - How are risers and sprues placed in sand molds?...Ch. 11 - In shell-mold casting, the curing process is...Ch. 11 - Why does the die-casting machine shown in Fig....Ch. 11 - Prob. 39QLPCh. 11 - What are the benefits to heating the mold in...Ch. 11 - The slushy state of alloys refers to that state...Ch. 11 - Can a chaplet also act as a chill? Explain.Ch. 11 - Rank the casting processes described in this...Ch. 11 - Estimate the clamping force for a die-casting...Ch. 11 - In sand casting, it is important that the...Ch. 11 - If an acceleration of 100 g is necessary to...Ch. 11 - A jeweler wishes to produce 24 gold rings in one...Ch. 11 - Describe the procedures that would be involved in...Ch. 11 - The optimum shape of a riser is spherical to...Ch. 11 - Sketch and describe a casting line consisting of...Ch. 11 - Outline the casting processes that would be most...Ch. 11 - Make a list of the mold and die materials used in...Ch. 11 - Write a brief paper on the permeability of molds...Ch. 11 - Light metals commonly are cast in vulcanized...Ch. 11 - It sometimes is desirable to cool metals more...Ch. 11 - The part shown in Fig. P11.59 is a hemispherical...Ch. 11 - Porosity that has developed in the boss of a...Ch. 11 - In Fig. II.1b the gemstones have been cast in...

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Please help, make sure it's to box out and make it clear what answers go where...arrow_forwardThe cylinder floats in the water and oil to the level shown. Determine the weight of the cylinder. (rho)o=910 kg/m^3arrow_forwardPlease help, make sure it's to box out and make it clear what answers go where..arrow_forward

- Please help, make sure it's to box out and make it clear what answers go where...arrow_forwardPlease help, make sure it's to box out and make it clear what answers go where...arrow_forwardA triangular distributed load of max intensity w acts on beam AB. The beam is supported by a pin at A and member CD, which is connected by pins at C and D respectively. Determine the largest load intensity, Wmax, that can be applied if the pin at D can support a maximum force of 18000 N. Also determine the reactions at A and C and express each answer in Cartesian components. Assume the masses of both beam and member ✓ are negligible. Dwas шал = A BY NC SA 2016 Eric Davishahl C D -a- Ур -b- X B W Values for dimensions on the figure are given in the following table. Note the figure may not be to scale. Variable Value a 6.6 m b 11.88 m C 4.29 m The maximum load intensity is = wmax N/m. The reaction at A is A = The reaction at C is = i+ Ĵ N. ĴN. 12 i+arrow_forward

- The beam is supported by a pin at B and a roller at C and is subjected to the loading shown with w =110 lb/ft, and F 205 lb. a.) If M = 2,590 ft-lb, determine the support reactions at B and C. Report your answers in both Cartesian components. b.) Determine the largest magnitude of the applied couple M for which the beam is still properly supported in equilibrium with the pin and roller as shown. 2013 Michael Swanbom CC BY NC SA M ру W B⚫ C F ka b Values for dimensions on the figure are given in the following table. Note the figure may not be to scale. Variable Value a 3.2 ft b 6.4 ft C 3 ft a.) The reaction at B is B = The reaction at C is C = ĵ lb. i+ Ĵ lb. b.) The largest couple that can be applied is M ft-lb. == i+arrow_forwardThe beam ABC has a mass of 79.0 kg and is supported by the rope BDC that runs through the frictionless pulley at D . The winch at C has a mass of 36.5 kg. The tension in the rope acts on the beam at points B and C and counteracts the moments due to the beam's weight (acting vertically at the midpoint of its length) and the weight of the winch (acting vertically at point C) such that the resultant moment about point A is equal to zero. Assume that rope segment CD is vertical and note that rope segment BD is NOT necessarily perpendicular to the beam. a.) Compute the tension in the rope. b.) Model the two forces the rope exerts on the beam as a single equivalent force and couple moment acting at point B. Enter your answer in Cartesian components. c.) Model the two forces the rope exerts on the beam as a single equivalent force (no couple) and determine the distance from A to the point along the beam where the equivalent force acts (measured parallel to the beam from A ). Enter your answer…arrow_forwardw1 Three distributed loads act on a beam as shown. The load between A and B increases linearly from 0 to a maximum intensity of w₁ = 12.8 lb/ft at point B. The load then varies linearly with a different slope to an intensity of w₂ = 17.1 lb/ft at C. The load intensity in section CD of the beam is constant at w3 10.2 lb/ft. For each load region, determine the resultant force and the location of its line of action (distance to the right of A for all cases). cc 10 BY NC SA 2016 Eric Davishahl = WI W2 W3 -b- C Values for dimensions on the figure are given in the following table. Note the figure may not be to scale. Variable Value a 4.50 ft b 5.85 ft с 4.28 ft The resultant load in region AB is FR₁ = lb and acts ft to the right of A. The resultant load in region BC is FR2 lb and acts = ft to the right of A. The resultant load in region CD is FR3 = lb and acts ft to the right of A.arrow_forward

- The T-shaped structure is embedded in a concrete wall at A and subjected to the force F₁ and the force-couple system F2 1650 N and M = 1,800 N-m at the locations shown. Neglect the weight of the structure in your calculations for this problem. = a.) Compute the allowable range of magnitudes for F₁ in the direction shown if the connection at A will fail when subjected to a resultant moment with a magnitude of 920 N- m or higher. b.) Focusing on the forces and igonoring given M for now. Using the value for F1, min that you calculated in (a), replace the two forces F₁ and F2 with a single force that has equivalent effect on the structure. Specify the equivalent →> force Feq in Cartesian components and indicate the horizontal distance from point A to its line of action (note this line of action may not intersect the structure). c.) Now, model the entire force system (F1,min, F2, and M) as a single force and couple acting at the junction of the horizontal and vertical sections of the…arrow_forwardThe heated rod from Problem 3 is subject to a volumetric heating h(x) = h0 x L in units of [Wm−3], as shown in the figure below. Under the heat supply the temperature of the rod changes along x with the temperature function T (x). The temperature T (x) is governed by the d following equations: − dx (q(x)) + h(x) = 0 PDE q(x) =−k dT dx Fourier’s law of heat conduction (4) where q(x) is the heat flux through the rod and k is the (constant) thermal conductivity. Both ends of the bar are in contact with a heat reservoir at zero temperature. Determine: 1. Appropriate BCs for this physical problem. 2. The temperature function T (x). 3. The heat flux function q(x). Side Note: Please see that both ends of bar are in contact with a heat reservoir at zero temperature so the boundary condition at the right cannot be du/dx=0 because its not thermally insulated. Thank youarrow_forwardThe elastic bar from Problem 1 spins with angular velocity ω about an axis, as shown in the figure below. The radial acceleration at a generic point x along the bar is a(x) = ω2x. Under this radial acceleration, the bar stretches along x with displacement function u(x). The displacement d u(x) is governed by the following equations: dx (σ(x)) + ρa(x) = 0 PDE σ(x) = E du dx Hooke’s law (2) where σ(x) is the axial stress in the rod, ρ is the mass density, and E is the (constant) Young’s modulus. The bar is pinned on the rotation axis at x = 0 and it is also pinned at x = L. Determine: 1. Appropriate BCs for this physical problem. 2. The displacement function u(x). 3. The stress function σ(x). SIDE QUESTION: I saw a tutor solve it before but I didn't understand why the tutor did not divide E under the second term (c1x) before finding u(x). The tutor only divided E under first term. please explain and thank youarrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY

Casting Metal: the Basics; Author: Casting the Future;https://www.youtube.com/watch?v=2CIcvB72dmk;License: Standard youtube license