Your engineering consulting firm has been sent the design for a simple piping system connecting two large water reservoirs (both at 10 °C) as shown in the accompanying figure. 2₁-19m ₁ Sharp-edged entrance, K₁ = 0.5 i) ii) -Control volume boundary -Standard elbow, flanged, K₁= 0.3 -90 m Gate valve, fully open K₁=0.2- P2₂₂ √₂ = 0 22₂2=4m a. Your client has informed you that this system is scheduled to operate for many years. Thus, they want you to determine the flow rate in the cast-iron 5" SCH80 piping for two conditions: The "best case" scenario where the piping is brand new. The "worst case" scenario (according to what is mentioned in Daugherty & Franzini's book Fluid Mechanics with Engineering Applications) where the piping has become all rusty on the inside. b. In order to eliminate the change in flow rate over time that you predict will happen in part a), a colleague suggests partially closing the gate valve when the piping is brand new and then gradually opening it as the piping becomes more and more rusty on the inside. By citing specific terms in the Bernoulli equation, give a brief explanation on how this technique works. c. Determine the gate valve loss coefficient that must be set to initially when the piping is brand new so that the flow rate of water matches the final conditions (i.e, when the piping has become all rusty on the inside and the gate valve is fully opened).

Your engineering consulting firm has been sent the design for a simple piping system connecting two large water reservoirs (both at 10 °C) as shown in the accompanying figure. 2₁-19m ₁ Sharp-edged entrance, K₁ = 0.5 i) ii) -Control volume boundary -Standard elbow, flanged, K₁= 0.3 -90 m Gate valve, fully open K₁=0.2- P2₂₂ √₂ = 0 22₂2=4m a. Your client has informed you that this system is scheduled to operate for many years. Thus, they want you to determine the flow rate in the cast-iron 5" SCH80 piping for two conditions: The "best case" scenario where the piping is brand new. The "worst case" scenario (according to what is mentioned in Daugherty & Franzini's book Fluid Mechanics with Engineering Applications) where the piping has become all rusty on the inside. b. In order to eliminate the change in flow rate over time that you predict will happen in part a), a colleague suggests partially closing the gate valve when the piping is brand new and then gradually opening it as the piping becomes more and more rusty on the inside. By citing specific terms in the Bernoulli equation, give a brief explanation on how this technique works. c. Determine the gate valve loss coefficient that must be set to initially when the piping is brand new so that the flow rate of water matches the final conditions (i.e, when the piping has become all rusty on the inside and the gate valve is fully opened).

Elements Of Electromagnetics

7th Edition

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Sadiku, Matthew N. O.

ChapterMA: Math Assessment

Section: Chapter Questions

Problem 1.1MA

Related questions

Question

Please solve using moody chart

![Relative roughness & =

Surface

Copper, Lead, Brass, Aluminum (new)

PVC and Plastic Pipes

Epoxy, Vinyl Ester and Isophthalic pipe

Stainless steel

Steel commercial pipe

Stretched steel

Weld steel

Galvanized steel

Rusted steel (corrosion)

New cast iron

Worn cast iron

Rusty cast iron

Sheet or asphalted cast iron

Smoothed cement

Ordinary concrete

Coarse concrete

Well planed wood

Ordinary wood

e

D

Pipe roughness [=] length

Pipe diameter [=] length

Absolute Roughness - k

10³ (m)

0.001 -0.002

0.0015-0.007

0.005

0.015

0.045 -0.09

0.015

0.045

0.15

0.15-4

0.25 -0.8

0.8-1.5

1.5-2.5

0.01 -0.015

0.3

0.3-1

0.3-5

0.18-0.9

5

(feet)

3.3-6.7 106

0.5-2.33 10-5

1.7 10-5

5 10-5

1.5-3 104

5 10-5

1.5 104

5 104

5-133 104

8-27 104

2.7-510-3

5-8.3 10-3

3.33-510-5

1 10-3

1-3.33 10-3

1-16.7 10³

6-30 10-4

16.7 10-3

From Fluid Mechanics with

Engineering Applications

(Daugherty & Franzini):

39

"In planning for the future

capacities it must be recalled

that scale deposits will increase

the roughness and reduce the

cross-sectional area. For pipes

in water service, the absolute

roughness of old pipes (20

years and more) may increase

over that of new pipes by

threefold for concrete or

cement-lined steel, up to

twenty-fold for cast iron, and

even to forty-fold for

tuberculated wrought-iron and

steel pipe."

http://www.engineeringtoolbox.com/major-loss-ducts-tubes-d 459.html](/v2/_next/image?url=https%3A%2F%2Fcontent.bartleby.com%2Fqna-images%2Fquestion%2Fca6b5de9-d666-4be4-bec5-372f49facd74%2F792776cf-764b-4c45-9f98-7adeb8cd03cc%2Fau2xak_processed.jpeg&w=3840&q=75)

Transcribed Image Text:Relative roughness & =

Surface

Copper, Lead, Brass, Aluminum (new)

PVC and Plastic Pipes

Epoxy, Vinyl Ester and Isophthalic pipe

Stainless steel

Steel commercial pipe

Stretched steel

Weld steel

Galvanized steel

Rusted steel (corrosion)

New cast iron

Worn cast iron

Rusty cast iron

Sheet or asphalted cast iron

Smoothed cement

Ordinary concrete

Coarse concrete

Well planed wood

Ordinary wood

e

D

Pipe roughness [=] length

Pipe diameter [=] length

Absolute Roughness - k

10³ (m)

0.001 -0.002

0.0015-0.007

0.005

0.015

0.045 -0.09

0.015

0.045

0.15

0.15-4

0.25 -0.8

0.8-1.5

1.5-2.5

0.01 -0.015

0.3

0.3-1

0.3-5

0.18-0.9

5

(feet)

3.3-6.7 106

0.5-2.33 10-5

1.7 10-5

5 10-5

1.5-3 104

5 10-5

1.5 104

5 104

5-133 104

8-27 104

2.7-510-3

5-8.3 10-3

3.33-510-5

1 10-3

1-3.33 10-3

1-16.7 10³

6-30 10-4

16.7 10-3

From Fluid Mechanics with

Engineering Applications

(Daugherty & Franzini):

39

"In planning for the future

capacities it must be recalled

that scale deposits will increase

the roughness and reduce the

cross-sectional area. For pipes

in water service, the absolute

roughness of old pipes (20

years and more) may increase

over that of new pipes by

threefold for concrete or

cement-lined steel, up to

twenty-fold for cast iron, and

even to forty-fold for

tuberculated wrought-iron and

steel pipe."

http://www.engineeringtoolbox.com/major-loss-ducts-tubes-d 459.html

Transcribed Image Text:QUESTION 4

Your engineering consulting firm has been sent the design for a simple piping system connecting two large water

reservoirs (both at 10 °C) as shown in the accompanying figure.

2₁-19m ₁

i)

ii)

Sharp-edged

entrance, K₂ = 0.5

-Control

volume

туре II

Guess

e

boundary

9 m

a. Your client has informed you that this system is scheduled to operate for many years. Thus, they want you to

determine the flow rate in the cast-iron 5" SCH80 piping for two conditions:

The "best case" scenario where the piping is brand new.

The "worst case" scenario (according to what is mentioned in Daugherty & Franzini's book

Fluid Mechanics with Engineering Applications) where the piping has become all rusty on the

inside.

-Standard elbow,

flanged, K₁ = 0.3

f=

-90 m

b. In order to eliminate the change in flow rate over time that you predict will happen in part a), a colleague

suggests partially closing the gate valve when the piping is brand new and then gradually opening it as the

piping becomes more and more rusty on the inside. By citing specific terms in the Bernoulli equation, give a

brief explanation on how this technique works.

?

Gate valve,

fully open

K₁=0.2-

c. Determine the gate valve loss coefficient that must be set to initially when the piping is brand new so that the

flow rate of water matches the final conditions (i.e, when the piping has become all rusty on the inside and

the gate valve is fully opened).

~0

P₁ = P₂

V/₂=0

Zy

P₂₂ √₂ = 0

2₂=4m

e = 0.26mm = 0.00026m

Internal diameter = 0.41011 ft + 3.281

= 0.122m

Z₂

2

0.00026m = 0.00213

0.122m

2

Expert Solution

This question has been solved!

Explore an expertly crafted, step-by-step solution for a thorough understanding of key concepts.

Step by step

Solved in 4 steps with 6 images

Follow-up Questions

Read through expert solutions to related follow-up questions below.

Follow-up Question

Where did you get these values from? Like the density, u?

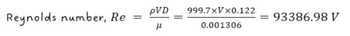

Transcribed Image Text:Reynolds number, Re

=

pVD 999.7xVx0.122

μ

0.001306

=

=

93386.98 V

Solution

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Recommended textbooks for you

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Elements Of Electromagnetics

Mechanical Engineering

ISBN:

9780190698614

Author:

Sadiku, Matthew N. O.

Publisher:

Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:

9780134319650

Author:

Russell C. Hibbeler

Publisher:

PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:

9781259822674

Author:

Yunus A. Cengel Dr., Michael A. Boles

Publisher:

McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:

9781118170519

Author:

Norman S. Nise

Publisher:

WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:

9781337093347

Author:

Barry J. Goodno, James M. Gere

Publisher:

Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:

9781118807330

Author:

James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:

WILEY