‘Ceramic Bearing Manufacturing Methods’ , ‘Wear Characteristic of Ceramic Bearings’ , ‘Elastic Deformation of Ceramic Bearings’, ‘Ceramic Bearing Applications’, Ceramic Bearing Failure Mechanism)

Seramik rulmanlar nasıl imal edilir? Seramik rulmanların ezilme ve aşınma karakteristiği hakkında bilgi veriniz? Seramik rulmanlar hangi uygulamalarda neden kullanılır ? anahtar kelimeler ‘Ceramic Bearing Manufacturing Methods’ , ‘Wear Characteristic of Ceramic Bearings’ , ‘Elastic Deformation of Ceramic Bearings’, ‘Ceramic Bearing Applications’, Ceramic Bearing Failure

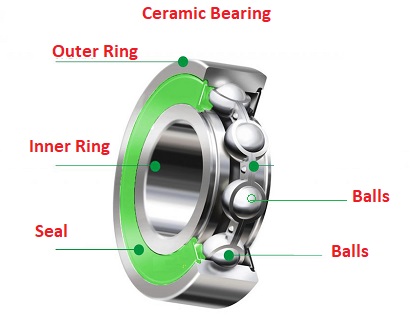

Ceramic Bearings:

Ceramic Bearings consist of the ceramic rolling elements (often known as balls) enclosing in the inner and outer races made up of ferrous alloys. These bearings are manufactured by the application of a hot isostatic process that results in multi-axial compressing to obtain the uniform component of bearing.

These bearings have the varying hardness and elastic deformation capacity depending upon the type of rolling material used. The rolling material in these bearings includes the following materials.

These bearings have the varying hardness and elastic deformation capacity depending upon the type of rolling material used. The rolling material in these bearings includes the following materials.

- Aluminum Oxide (Al2O3)

- Silicon Nitride (Si3N4)

- Silicon Carbide (SiC)

Wear characteristics and failure mechanism of Ceramic Bearing:

The tribological (wear and friction) studies of ceramic bearings do not suggest optimistic and good results. The friction coefficient of these bearings is very high. It ranges from 0.5 to 1. The wear rates are also observed very high despite a good surface finish or use of a polished surface. These bearings generally result in a grain-boundary defect. The tensile strength and ductility of these bearings are very low and their hardness is very high. The low tensile strength of these bearings is the reason behind the microfracture defect. High friction during the operation of these bearings generates tensile stress and tensile stress propagates the crack (wear) on the surface of bearing. These wear can lead to bearing failure when coupled with high stress due to high bearing pressure and loads.

Step by step

Solved in 4 steps with 1 images