Concept explainers

Question

☆New England Foundry

For more than 75 years, New England Foundry, Inc. (NEFI), has manufactured wood stoves for home use. In recent years, with increasing energy prices, president George Mathison has seen sales triple. This dramatic increase has made it difficult for George to maintain quality in all his wood stoves and related products.

Unlike other companies manufacturing wood stoves, NEFI is in the business of making only stoves and stove-related products. Its major products are the Warmglo I, the Warmglo II, the Warmglo III, and the Warmglo IV. The Warmglo I is the smallest wood stove, with a heat output of 30,000 BTUs, and the Warmglo IV is the largest, with a heat output of 60,000 BTUs.

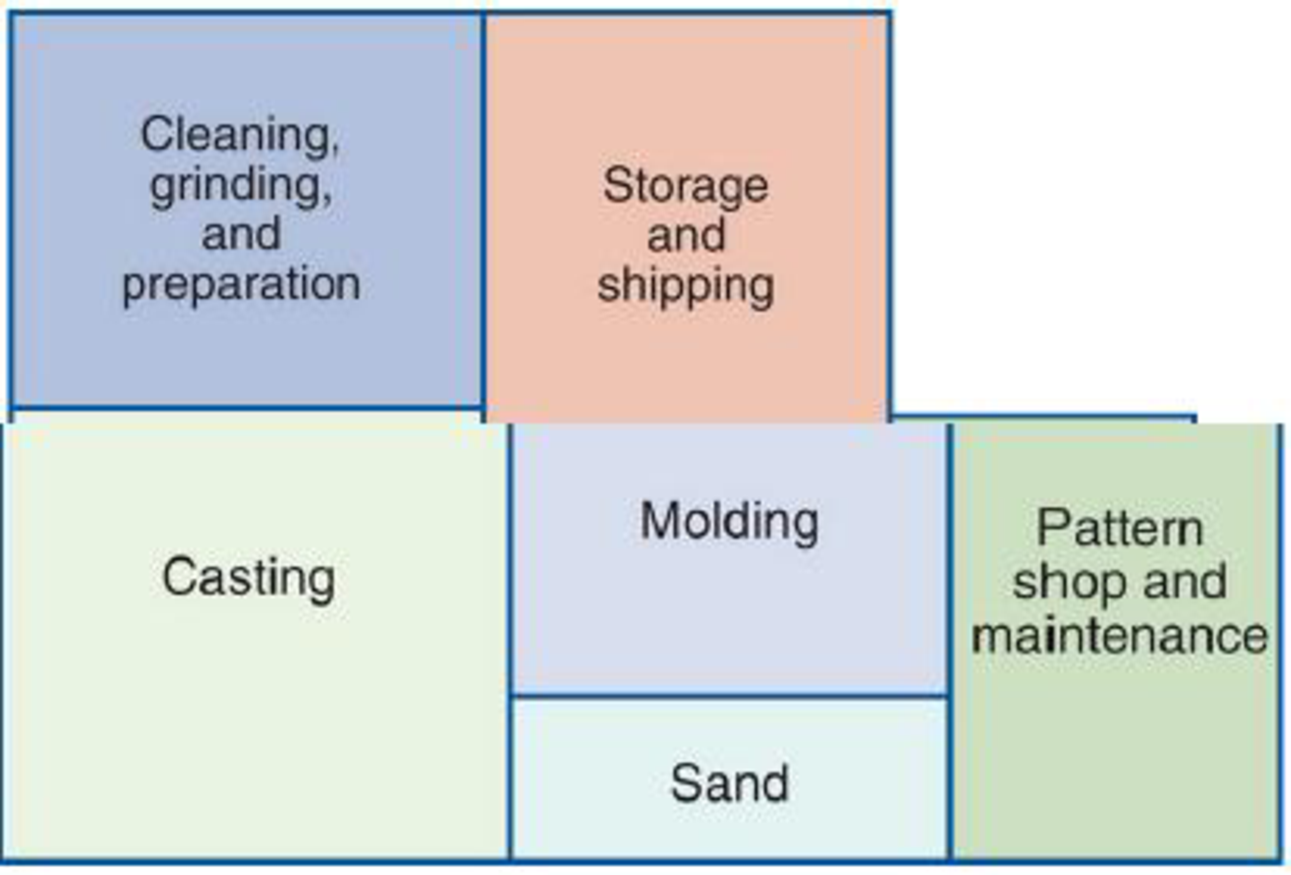

The Warmglo III outsold all other models by a wide margin. Its heat output and available accessories were ideal for the typical home. The Warmglo III also had a number of other outstanding features that made it one of the most attractive and heat-efficient stoves on the market. These features, along with the accessories, resulted in expanding sales and prompted George to build a new factory to manufacture the Warmglo III model. An overview diagram of the factory is shown in Figure D.6.

Figure D.6 Overview of Factory

The new foundry used the latest equipment, including a new Disamatic that helped in manufacturing stove parts. Regardless of new equipment or procedures, casting operations have remained basically unchanged for hundreds of years. To begin with, a wooden pattern is made for every cast-iron piece in the stove. The wooden pattern is an exact duplicate of the cast-iron piece that is to be manufactured. All NEFI patterns are made by Precision Patterns, Inc. and are stored in the pattern shop and maintenance room. Next, a specially formulated sand is molded around the wooden pattern. There can be two or more sand molds for each pattern. The sand is mixed and the molds are made in the molding room. When the wooden pattern is removed, the resulting sand molds form a negative image of the desired casting.

Next, molds are transported to the casting room, where molten iron is poured into them and allowed to cool. When the iron has solidified, molds are moved into the cleaning, grinding, and preparation room, where they are dumped into large vibrators that shake most of the sand from the casting. The rough castings are then subjected to both sandblasting to remove the rest of the sand and grinding to finish some of their surfaces. Castings are then painted with a special heat-resistant paint, assembled into workable stoves, and inspected for manufacturing defects that may have gone undetected. Finally, finished stoves are moved to storage and shipping, where they are packaged and transported to the appropriate locations.

At present, the pattern shop and the maintenance department are located in the same room. One large counter is used by both maintenance personnel, who store tools and parts (which are mainly used by the casting department), and sand molders, who need various patterns for the molding operation. Pete Nawler and Bob Dillman, who work behind the counter, can service a total of 10 people per hour (about 5 per hour each). On average, 4 people from casting and 3 from molding arrive at the counter each hour. People from molding and casting departments arrive randomly, and to be served, 1hey form a single line.

Pete and Bob have always had a policy of first come, first served. Because of the location of the pattern shop and maintenance department, it takes an average of 3 minutes for an individual from the casting department to walk to the pattern and maintenance room, and it takes about 1 minute for an individual to walk from the molding department to the pattern and maintenance room.

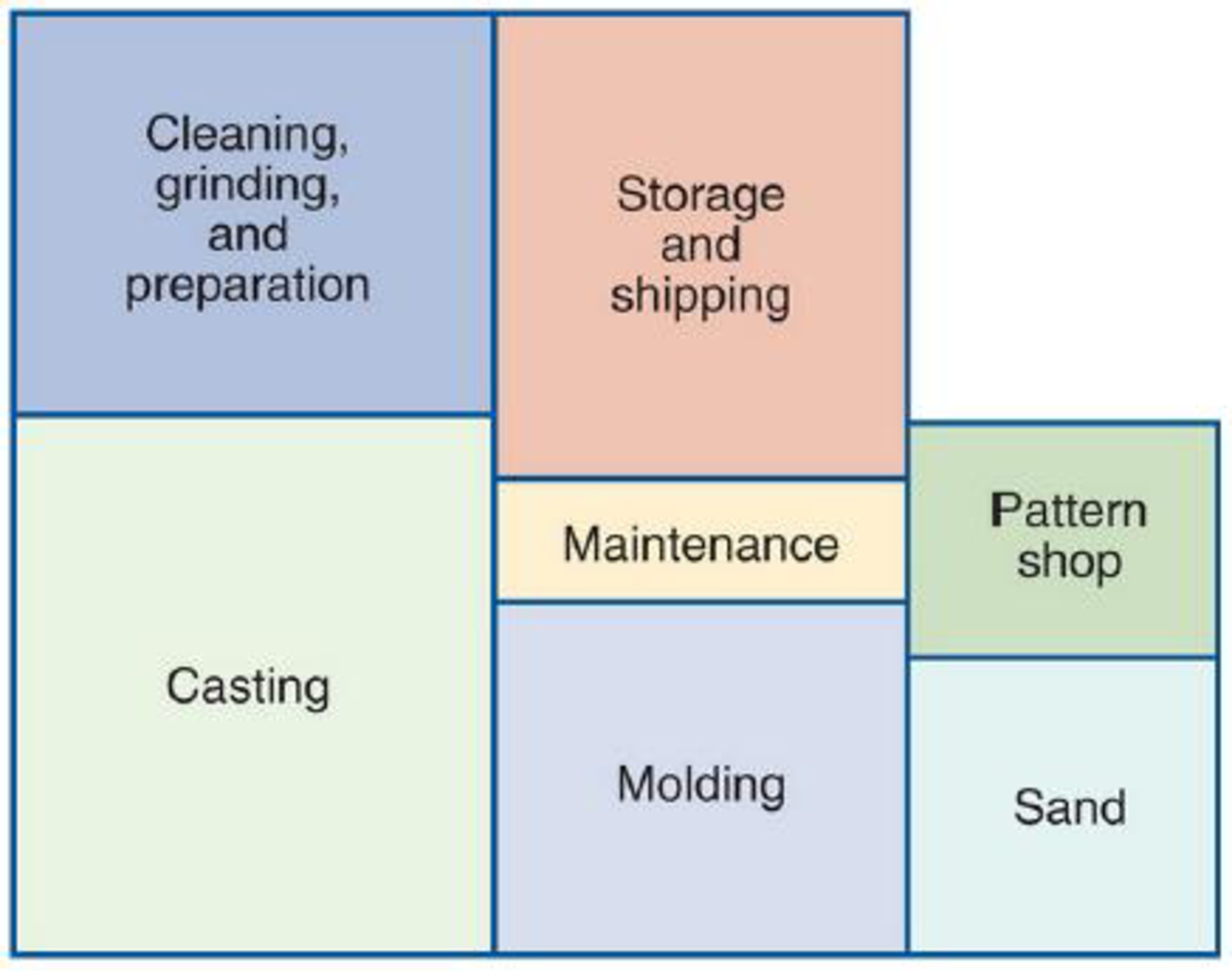

After observing the operation of the pattern shop and maintenance room for several weeks, George decided to make some changes to the factory layout. An overview of these changes appears in Figure D.7.

Figure D.7 Overview of Factory after Changes

Separating the maintenance shop from the pattern shop would have a number of advantages. It would take people from the casting department only 1 minute instead of 3 to get to the new maintenance room. The time from molding to the pattern shop would be unchanged. Using motion and time studies, George was also able to determine that improving the layout of the maintenance room would allow Bob to serve 6 people from the casting department per hour; improving the layout of the pattern department would allow Pete to serve 7 people from the molding shop per hour.

1. How much time would the new layout save?

Want to see the full answer?

Check out a sample textbook solution

Chapter D Solutions

Operations Management: Sustainability and Supply Chain Management, Student Value Edition Plus MyLab Operations Management with Pearson eText -- Access Card Package (12th Edition)

- FORMATIVE ASSESSMENT 1 Read the article below and answer ALL the questions Pick n Pay reveals strategy to restore its business 27 May 2024 [100 MARKS] Following a disappointing full year performance for FY24, Pick n Pay CEO Sean Summers has unveiled the new board- approved six-point strategy to restore the Group's core Pick n Pay supermarket business to profitability. PHASED APPROACH IMPLEMENTATION Leverage strength of partnerships Leadership and people 2 Reset the store estate 3 Improve offer to drive sales 4 Optimise operating model Leverage strength of partnerships Recapitalisation Pick n Pay Prod FY26 FY27 Before Tax break-even FY25 Halve Group H2 FY24 H1 FY25 H2 FY25 H1 FY26 H2 FY26 HI FY27 H2 FY27 KEY IMPACT AND/OR TARGETED OUTCOMES Appointing the right people, in the optimal roles, to Directly and indirectly impact revenue growth drivers and 1 drive sales and realise margin improvement 5 enhances gross and operating margins 2 Expected notable associated savings/loss avoidance…arrow_forwardWith an enormous amount of data stored in databases and data warehouses, it is increasinglyimportant to develop powerful tools for analysis of such data and mining interestingknowledge from it. Data mining is a process of inferring knowledge from such huge data. Themain problem related to the retrieval of information from the World Wide Web is theenormous number of unstructured documents and resources, i.e., the difficulty of locating andtracking appropriate sources. Your company is considering investing in a Human Resource Information System (HRIS).Briefly explain the strategies for justifying HRIS investments.arrow_forwardYour company is considering investing in a Human Resource Information System (HRIS).Briefly explain the strategies for justifying HRIS investments.arrow_forward

- EXPLAIN Human Resource Information System (HRIS)arrow_forwardRead the mini-case study below and answer the following questions.With an enormous amount of data stored in databases and data warehouses, it is increasinglyimportant to develop powerful tools for analysis of such data and mining interestingknowledge from it. Data mining is a process of inferring knowledge from such huge data. Themain problem related to the retrieval of information from the World Wide Web is theenormous number of unstructured documents and resources, i.e., the difficulty of locating andtracking appropriate sources.Briefly explain any five (5) types of information you can get from data mining.arrow_forwardProblem 1: Practice Problems Chapter 6 Managing Quality The accounts receivable department has documented the following defects over a 30-day period: Category Frequency Invoice amount does not agree with the check amount 108 Invoice not on record (not found) 24 No formal invoice issued Check (payment) not received on time 18 30 Check not signed 8 Invoice number and invoice referenced do not agree 12 What techniques would you use and what conclusions can you draw about defects in the accounts receivable department? Problem 2: Prepare a flow chart for purchasing a Big Mac at the drive-through window at McDonalds. Problem 3: Draw a fishbone chart detailing reasons why a part might not be correctly machined.arrow_forward

- Problem 5: Development of a new deluxe version of a particular software product is being considered. The activities necessary for the completion of this project are listed in the table below along with their costs and completion times in weeks. Activity Normal Crash Normal Crash Immediate Time Time Cost Cost Predecessor A 4 3 2,000 2,600 B 2 1 2,200 2,800 A C 3 3 500 500 A D 8 4 2,300 2,600 A E 6 3 900 1,200 B, D F 3 2 3,000 4,200 C, E G 4 2 1,400 2,000 F a. What is the project expected completion date? b. What is the total cost required for completing this project on normal time? c. If you wish to reduce the time required to complete this project by 1 week, which activity should be crashed, and how much will this increase the total cost?arrow_forwardI need answer typing clear urjent no chatgpt used pls i will give 5 Upvotes.with diagramarrow_forwardnot use ai pleasearrow_forward

- provide scholarly reseach and references for the following 1. explain operational risks and examples of such risk faced by management at financial institutions 2. discuss the importance of establishing an effective risk management policy at financial institutions to manage operational risk, giving example of a risk management strategy used by financial institutions to mitigate such risk. 3. what is the rold of the core principles of effective bank supervision as it relates to operational risk, in the effective management of financial institutions.arrow_forwardPlease show all units, work, and steps needed to solve this problem I need answer typing clear urjent no chatgpt used pls i will give 5 Upvotes.arrow_forwardIM.82 A distributor of industrial equipment purchases specialized compressors for use in air conditioners. The regular price is $50, however, the manufacturer of this compressor offers quantity discounts per the following discount schedule: Option Plan Quantity Discount A 1 - 299 0% B 300 - 1,199 0.50% C 1,200+ 1.50% The distributor pays $56 each time it places an order with the manufacturer. Holding costs are negligible (none) but they do earn 10% annual interest on all cash balances (meaning there will be a financial opportunity cost when they put cash into inventory). Annual demand is expected to be 10,750 units. When there is no quantity discount (Option Plan A, the first row of the schedule listed above), what is the adjusted order quantity? (Display your answer to the nearest whole number.) 491 Based on your answer to the previous question, and based on the annual demand as stated above, what will be the annual ordering costs? (Display your answer to the…arrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,