Concept explainers

8.9 through 8.14 Each of the following problems refers to a rolled-steel shape selected in a problem of Chap. 5 to support a given loading at a minimal cost while satisfying the requirement σm ≤ σall. For the selected design, determine (a) the actual value of σm in the beam, (b) the maximum value of the principal stress σmax at the junction of a flange and the web.

8.14 Loading of Prob. 5.78 and selected S460 × 81.4 shape.

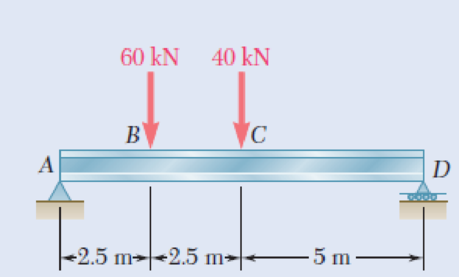

Fig. P5.78

(a)

The actual value of

Answer to Problem 14P

The actual value of

Explanation of Solution

Given information:

Refer to problem 5.78 in chapter 5 in the textbook.

The allowable normal stress of the beam is

Calculation:

Design of beam:

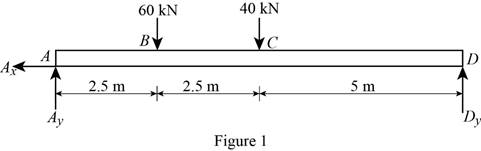

Show the free-body diagram of the beam as in Figure 1.

Determine the vertical reaction at point D by taking moment at point A.

Determine the vertical reaction at point A by resolving the vertical component of forces.

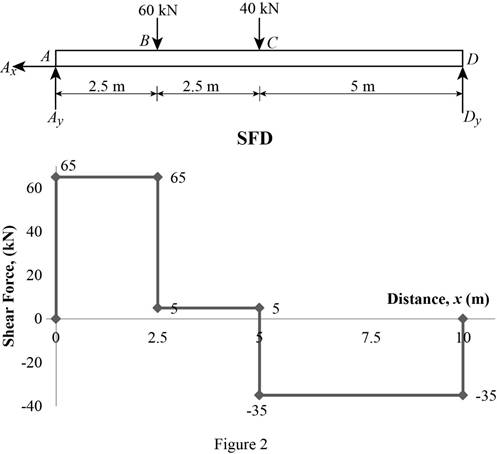

Shear force:

Show the calculation of shear force as follows;

Show the calculated shear force values as in Table 1.

| Location (x) m | Shear force (V) kN |

| A | 65 |

| B (Left) | 65 |

| B (Right) | 5 |

| C (Left) | 5 |

| C (Right) | –35 |

| D | –35 |

Plot the shear force diagram as in Figure 2.

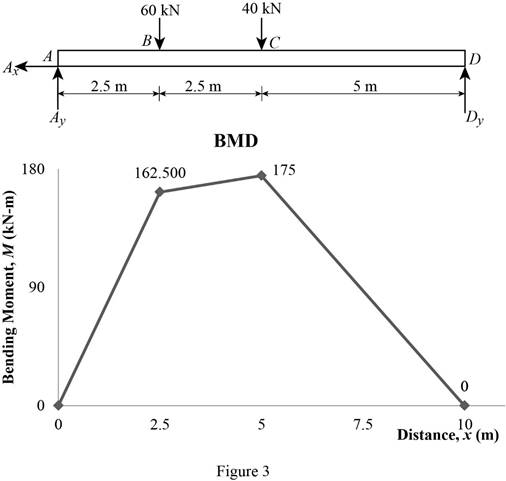

Bending moment:

Show the calculation of the bending moment as follows;

Show the calculated bending moment values as in Table 2.

| Location (x) m | Bending moment (M) kN-m |

| A | 0 |

| B | 162.5 |

| C | 175 |

| D | 0 |

Plot the bending moment diagram as in Figure 3.

Refer to the Figure 3;

The maximum bending moment in the beam is

Write the section a property for a

| Dimension | Unit( |

| d | 457 |

| 152 | |

| 17.6 | |

Here, d is depth of the section,

Find the value of C using the relation:

Substitute

Find the maximum value of normal stress

Here,

Substitute

Thus, the actual value of

(b)

The maximum value of principal stress

Answer to Problem 14P

The maximum value of principal stress

Explanation of Solution

Calculation:

Find the value

Here, c is the centroid and

Substitute

Find the area of flange

Here,

Substitute

Find the centroid of flange

Substitute

Find the first moment about neutral axis

Here,

Substitute

At section C,

Find the value of

Here, actual value of normal stress

Substitute

Find the shear stress at

Modify Equation (8).

Substitute

Find the maximum shearing stress (R) using the relation:

Here,

Substitute

Determine the maximum value of the principle stress using the relation:

Here, R is the maximum shearing stress and

Substitute

At section B,

Find the maximum value of normal stress

Here,

Substitute

Find the value of

Substitute

Find the shear stress at b

Substitute

Refer to figure 3.

Substitute

Find the maximum shearing stress (R) using the relation:

Here,

Substitute

Determine the maximum value of the principle stress using the relation:

Here, R is the maximum shearing stress and

Substitute

Based on results,

Select the maximum value of principal stress

Thus, the maximum value of principal stress

Want to see more full solutions like this?

Chapter 8 Solutions

EBK MECHANICS OF MATERIALS

Additional Engineering Textbook Solutions

Vector Mechanics For Engineers

Database Concepts (8th Edition)

Electric Circuits. (11th Edition)

Mechanics of Materials (10th Edition)

Thermodynamics: An Engineering Approach

Automotive Technology: Principles, Diagnosis, And Service (6th Edition) (halderman Automotive Series)

- CORRECT AND DETAILED SOLUTION WITH FBD ONLY. I WILL UPVOTE THANK YOU. CORRECT ANSWER IS ALREADY PROVIDED. I REALLY NEED FBD. The roof truss shown carries roof loads, where P = 10 kN. The truss is consisting of circular arcs top andbottom chords with radii R + h and R, respectively.Given: h = 1.2 m, R = 10 m, s = 2 m.Allowable member stresses:Tension = 250 MPaCompression = 180 MPa1. If member KL has square section, determine the minimum dimension (mm).2. If member KL has circular section, determine the minimum diameter (mm).3. If member GH has circular section, determine the minimum diameter (mm).ANSWERS: (1) 31.73 mm; (2) 35.81 mm; (3) 18.49 mmarrow_forwardPROBLEM 3.23 3.23 Under normal operating condi- tions a motor exerts a torque of magnitude TF at F. The shafts are made of a steel for which the allowable shearing stress is 82 MPa and have diameters of dCDE=24 mm and dFGH = 20 mm. Knowing that rp = 165 mm and rg114 mm, deter- mine the largest torque TF which may be exerted at F. TF F rG- rp B CH TE Earrow_forward1. (16%) (a) If a ductile material fails under pure torsion, please explain the failure mode and describe the observed plane of failure. (b) Suppose a prismatic beam is subjected to equal and opposite couples as shown in Fig. 1. Please sketch the deformation and the stress distribution of the cross section. M M Fig. 1 (c) Describe the definition of the neutral axis. (d) Describe the definition of the modular ratio.arrow_forward

- using the theorem of three moments, find all the moments, I only need concise calculations with minimal explanations. The correct answers are provided at the bottomarrow_forwardMechanics of materialsarrow_forwardusing the theorem of three moments, find all the moments, I need concise calculations onlyarrow_forward

- Can you provide steps and an explaination on how the height value to calculate the Pressure at point B is (-5-3.5) and the solution is 86.4kPa.arrow_forwardPROBLEM 3.46 The solid cylindrical rod BC of length L = 600 mm is attached to the rigid lever AB of length a = 380 mm and to the support at C. When a 500 N force P is applied at A, design specifications require that the displacement of A not exceed 25 mm when a 500 N force P is applied at A For the material indicated determine the required diameter of the rod. Aluminium: Tall = 65 MPa, G = 27 GPa. Aarrow_forwardFind the equivalent mass of the rocker arm assembly with respect to the x coordinate. k₁ mi m2 k₁arrow_forward

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY