Concept explainers

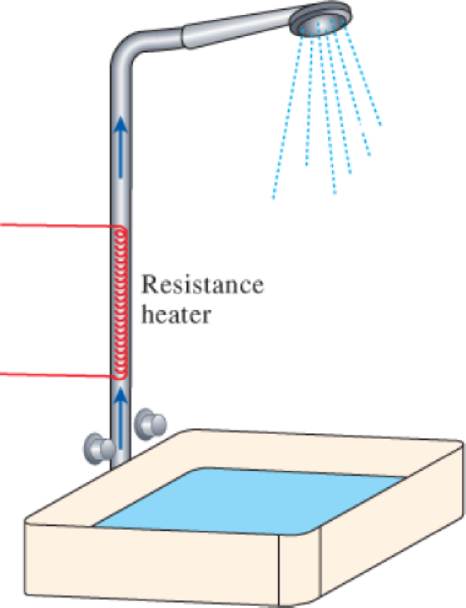

- (a) Water flows through a shower head steadily at a rate of 10 L/min. An electric resistance heater placed in the water pipe heats the water from 16 to 43°C. Taking the density of water to be 1 kg/L, determine the electric power input to the heater in kW and the rate of entropy generation during this process in kW/K.

FIGURE P7–209

- (b) In an effort to conserve energy, it is proposed to pass the drained warm water at a temperature of 39°C through a heat exchanger to preheat the incoming cold water. If the heat exchanger has an effectiveness of 0.50 (that is, it recovers only half of the energy that can possibly be transferred from the drained water to incoming cold water), determine the electric power input required in this case and the reduction in the rate of entropy generation in the resistance heating section.

a)

The electric power input to the heater and the rate of entropy generation during the process.

Answer to Problem 209RP

The electric power input to the heater is

The rate of entropy generation during the process is

Explanation of Solution

Write the expression for the energy balance of steady flow system.

Here, rate of net energy transfer in to the control volume is

Write the expression to calculate the mass flow rate

Here, density of water at room temperature is

Write the expression for the entropy balance equation of the system for steady flow process.

Here, rate of net entropy in is

Conclusion:

There is only one exit and one inlet, write the equation for the mass balance of steady flow system as,

Here, mass flow rate of water at inlet is

The rate of change in internal energy of system inside the system is zero at steady state,

Substitute 0 for

Here, electric power input to the heater is

From Table A-3 “Properties of common liquids, solids and foods”, the value for the density

Substitute

Substitute

Thus, the electric power input to the heater is

Substitute

Since, water is incompressible substance,

Here, rate of entropy generation at stage 1 is

Substitute

Thus, the rate of entropy generation during the process is

b)

The electric power input required and the reduction in the rate of entropy generation in the resistance heating section.

Answer to Problem 209RP

The electric power input required is

The reduction in the rate of entropy generation in the resistance heating section is

Explanation of Solution

Write the expression to calculate the energy saved

Here, effectiveness of heat exchanger is

Write the expression to calculate the required electric power

Here, electric power input to the heater is

Write the expression to calculate the temperature at which the cold water leaves heat exchanger.

Here, the energy saved is

Write the expression to calulate the entropy generation at stage 2.

Here, rate of entropy generation at stage 2 is

Write the expression to calculate the reduction in the rate of entropy generation within the heating section

Here, reduction in the rate of entropy generation is

Conclusion:

Substitute 0.5 for

Substitute

Substitute

Substitute

Substitute

Thus, the reduction in the rate of entropy generation in the resistance heating section is

Want to see more full solutions like this?

Chapter 7 Solutions

Thermodynamics: An Engineering Approach

- The primary material used in the production of glass products is silica sand. True or Falsearrow_forwardWhich one of the following is the most common polymer type in fiber-reinforced polymer composites? thermosets thermoplastics elastomers none of the abovearrow_forwardA pattern for a product is larger than the actual finished part. True or Falsearrow_forward

- Two forces are applied as shown to a hook support. The magnitude of P is 38 N. 50 N 25° DG a 터 Using trigonometry, determine the required angle a such that the resultant R of the two forces applied to the support will be horizontal. The value of a isarrow_forwardNo chatgpt pls will upvotearrow_forward101 the three shafts if the diameter ratio is 2 (D/d = 2)? Ans. na, tension = 1.21, na, bending = 1.19, na, torsion = 1.17. 6.32 A material with a yield strength of S₁ = 350 MPa is subjected to the stress state shown in Sketch c. What is the factor of safety based on the maximum shear stress and distortion energy theories? Ans. For MSST, n, = 11.67. 50 MPa 85 MPa 20 MPa 70 MPa Sketch c, for Problems 6.32 and 6.33arrow_forward

- Can you draw the left view of the first orthographic projectionarrow_forwardImportant: I've posted this question twice and received incorrect answers. I've clearly stated that I don't require AI-generated working out. I need a genuine, expert-written solution with proper working. If you can't provide that, refer this question to someone who can please!. Note: Please provide a clear, step-by-step handwritten solution (no AI involvement). I require an expert-level answer and will assess it based on quality and accuracy with that I'll give it a thumbs up or down!. Hence, refer to the provided image for clarity. Double-check everything for correctness before submitting. Thank you!arrow_forwardNote: Please provide a clear, step-by-step simplified handwritten working out (no explanations!), ensuring it is done without any AI involvement. I require an expert-level answer, and I will assess and rate based on the quality and accuracy of your work and refer to the provided image for more clarity. Make sure to double-check everything for correctness before submitting appreciate your time and effort!. Question:arrow_forward

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY