Concept explainers

a)

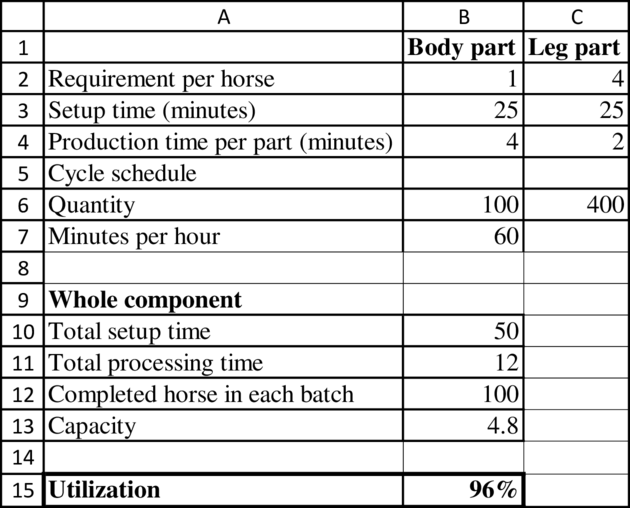

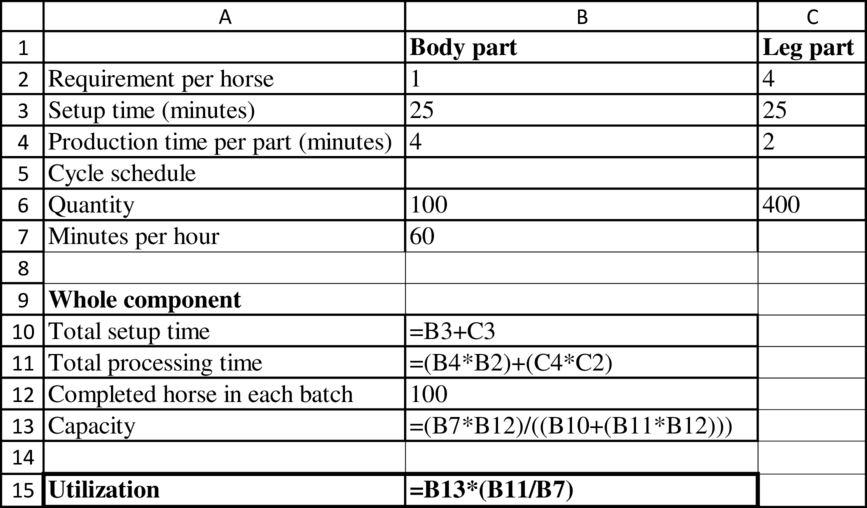

To determine: The maximum number horse sculptures that can be made in an hour.

a)

Explanation of Solution

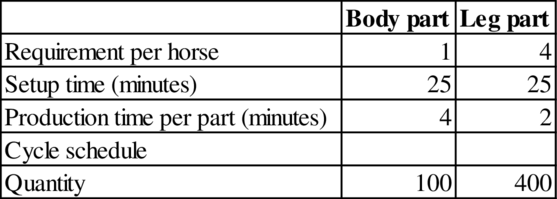

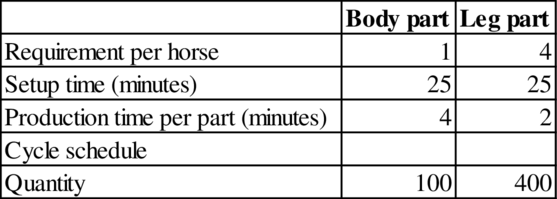

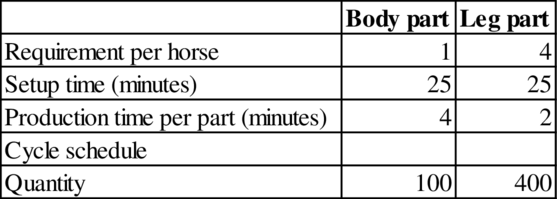

Given information:

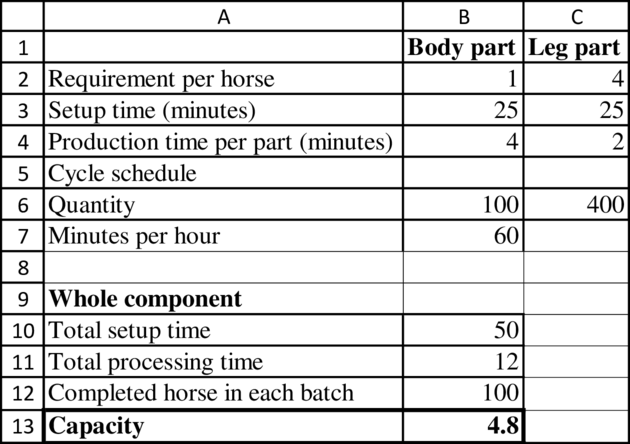

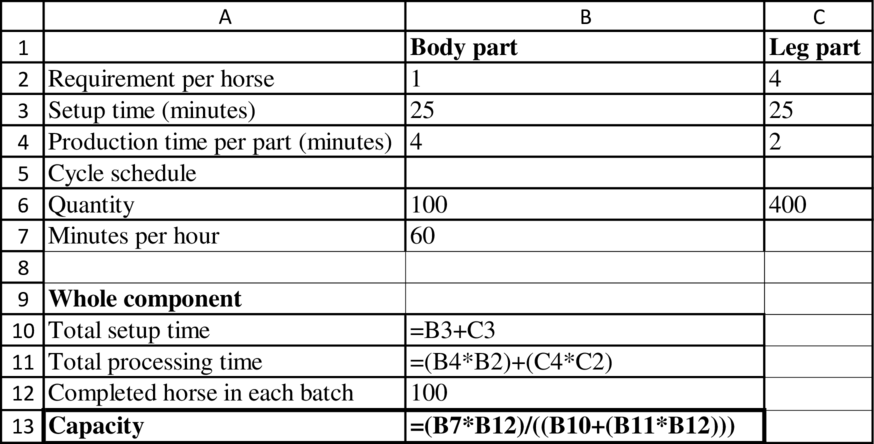

Calculation of maximum number of horses:

Formula:

The maximum number of horse sculptures made in an hour is 4.8.

b)

To determine: The utilization % of the lathe.

b)

Explanation of Solution

Given information:

Calculation of utilization of lathe:

Formula:

The utilization of lathe is 96%.

c)

To determine: The average inventory of body parts.

c)

Explanation of Solution

Given information:

1 worker can assemble the horse sculpture in 16 minutes.

Calculation of flow rate:

Calculation of average inventory:

The total batch size of legs is 100 and the processing time is 4 minutes.

The average inventory is 37.5 body.

d)

To determine: The average inventory of leg parts.

d)

Explanation of Solution

Given information:

1 worker can assemble the horse sculpture in 16 minutes.

Calculation of flow rate:

Calculation of average inventory:

The total batch size of legs is 400 and the processing time is 2 minutes.

The average inventory is 100 legs.

e)

To determine: The number of body parts that needs to be made to minimize the inventory while not constraining the flow through the assembly.

e)

Explanation of Solution

Given information:

1 worker can assemble the horse sculpture in 16 minutes.

Calculation of batch size:

The target capacity is the flow rate at 3.75 sculptures per hour. There is 1 body in each component set. Therefore, the batch size will be:

The body parts batch size is 12.5 body.

f)

To determine: The number of leg parts that needs to be made to minimize the inventory while not constraining the flow through the assembly.

f)

Explanation of Solution

Given information:

1 worker can assemble the horse sculpture in 16 minutes.

Calculation of batch size:

The target capacity is the flow rate at 3.75 sculptures per hour. There is 4 body in each component set. Therefore, the batch size will be:

The leg parts batch size is 50 leg.

Want to see more full solutions like this?

Chapter 7 Solutions

OPERATIONS MANAGEMENT W/ 360 DAY CONNECT

- LO3-1, 3-2, 3-4, 3-5 3. Consider a process consisting of three resources. Assume there exists unlimited demand for the product. a. Resource 1 has a processing time of 6 minutes per unit. b. Resource 2 has a processing time of 3 minutes per unit. c. Resource 3 has a processing time of 5 minutes per unit. All three resources are staffed by one worker. a. Draw a process flow diagram of this process. b. What is the capacity of resource 2? c. What is the bottleneck in the process? d. What is the utilization of resource 2? e. How long does it take the process to produce 200 units starting with an empty system, assuming this is a worker-paced process?arrow_forward1. It takes a barber 15 minutes to serve one customer. a. What is the capacity of the barber expressed in customers per hour? b. Assuming the demand for the barber is two customers per hour, what is the flow rate? c. Assuming the demand for the barber is two customers per hour, what is the utilization? d. Assuming the demand for the barber is two customers per hour, what is the cycle time?arrow_forward12 points) Jonathon's Restaurant is looking to open a new location. Caitlin Elizabeth has been developing a project plan and has identified tasks, precedence relations, and normal task durations shown in the table below: Assuming an indirect and overhead cost rate of 115, find the makespan and cost for a standard Early Start schedule: Makespan: Cost: Because Caitlin has studied project management at the University of Portland, she knows that a wise project manager should consider the trade-off between indirect/overhead costs and direct resource costs when establishing the "baseline" schedule. Assuming indirect/overhead costs of $115 per period and the direct compression costs and compression limits shown in the table above, find the following: Makespan: Cost: Compression strategy (enter answer as a vector: begin with "<", comma separated values, end with ">", e.g. < 0, 0, 5, ..., 2, 0>): Evidently this project is a very high priority project for Caitlin's boss.…arrow_forward

- Problem 1. (2 points) Jimbo's Java & Jerk is looking to implement a new labor scheduling system. Colin Alexander has been developing a project plan and has identified the following tasks, precedence relations, and normal task durations. Because Colin has studied project management at the University of Portland, he knows that the he should incorporate a time buffer into any estimates for the project's makespan. If Colin wants to quote a 90% makespan: Quoted Makespan = Time Buffer = Note: state all answers to two decimal places.arrow_forward1 point) Saint Teresa's Hospital is looking to implement a new ERP system. Ray Bones has been developing a project plan and has identified the following tasks, precedence relations, and normal task durations. Ray has studied project management at the University of Portland and knows that the starting and ending time of any task may be determined from the information in the table using the critical path method. Assume the following notation when answering the questions below: Please provide the CPM result for each of the following metrics:arrow_forwardWhy might there be commonalities or patterns in the retail industry between gross margin percentage and inventory turns with references?arrow_forward

- Is there a pattern between gross margin percentage and inventory turns in the retail industry?arrow_forwardA company that sells hardware goods has lower gross margins than others and lower turns, both not good. How can a firm in that position be profitable?arrow_forwardQuestion 1M&H company ltd. sells television sets and has collected monthly sales data (in units) for the past 12months as shown in table 1below: TABLE 1 Month Sales (Units)1 1202 1353 1504 1655 1806 2007 1958 2109 225 10 24011 25512 270 Using the data provided, answer the following questions: a. Using a 3-month weighted moving average with weights 0.5, 0.3, and 0.2 (most recent monthhaving the highest weight), calculate the forecast for month 13. b. If the company applies an exponential smoothing method with a smoothing constant (α) = 0.2,and assumes an initial forecast of 120 units for Month 1, calculate the forecast for month 13.c. Calculate the Mean Absolute Deviation (MAD) for the exponential smoothing method andweighted moving average method using the actual sales data for Months 4 to 12 and determinewhich method is more accurate. d. Compute the values of a (intercept) and b (slope) using the least squares method.e. Use the trend equation to forecast the demand for…arrow_forward

- You may need to use the appropriate technology to answer this question. An event hall that hosts public lectures, book readings, poetry slams, and other similar events uses a one-week periodic review inventory system for the throat lozenges that it stocks for its patrons. A two-day lead time is needed for any order, and the event hall is willing to tolerate an average of one stock-out per year. (a) Using the event hall's service guideline, what is the probability of a stock-out associated with each replenishment decision? (Round your answer to four decimal places.) (b) What is the replenishment level if demand during the review period plus lead-time period is normally distributed with a mean of 50 units and a standard deviation of 12 units? (Round your answer to the nearest integer.) (c) What is the replenishment level if demand during the review period plus lead-time period is uniformly distributed between 45 and 95 units? (Round your answer to the nearest integer.)arrow_forwardprovide scholarly research on the importance of internal risk assessement and auditng process in relation to US bank Cititbank loosing USD500 million in August 2020arrow_forwardThe annual requirements for a particular raw material are 2,000 units costing Re. 1 each to the manufacturer. The ordering cost is Rs. 10 per order and the carrying cost 16% per annum of the average inventory value. Find and explain the economic order quantity and the total inventory cost per annum.arrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,