MORTON SALT

Introduction

Morton Salt is a subsidiary of Morton International, a manufacturer of specialty chemicals, air bags, and salt products. The Morton salt-processing facility in Silver Springs, New York, between Buffalo and Rochester, is one of six similar Morton salt-processing facilities in the United States. The Silver Springs plant employs about 200 people, ranging from unskilled to skilled. It produces salt products for water conditioning, grocery, industrial, and agricultural markets. The grocery business consists of 26-oz. round cans of iodized salt. Although the grocery business represents a relatively small portion of the total output (approximately 15 percent), it is the most profitable.

Salt production

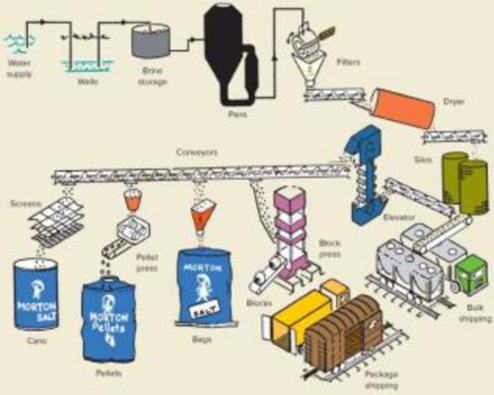

The basic raw material, salt, is obtained by injecting water into salt caverns that are located some 2,400 feet below the surface. There, the salt deposits dissolve in the water. The resulting brine is pumped to the surface where it is converted into salt crystals. The brine is boiled, and much of the liquid evaporates, leaving salt crystals and some residual moisture, which is removed in a drying process. This process is run continuously for about six weeks at a time. Initially, salt is produced at the rate of 45 tons per hour. But the rate of output decreases due to scale buildup, so that by the sixth week, output is only 75 percent of the initial rate. At that point, the process is halted to perform maintenance on the equipment and remove the scale, after which salt production resumes.

The salt is stored in silos until it is needed for production, or it is needed for production, or it is shipped in bulk to industrial customers. Conveyors move the salt to each of the four dedicated production areas, one of which is round can production (see diagram.). The discussion here focuses exclusively on round can production.

Round Can Production

Annual round can production averages roughly 3.8 million cans. Approximately 70 percent of the output is for the Morton label, and the rest is for private label. There are two parallel, high-speed production lines. The lines share common processes at the beginning of the lines, and then branch out into two identical lines. Each line is capable of producing 9,600 cans per hour (160 cans per minute). The equipment is not flexible, so the production rate is fixed. The operations are completely standardized; the only variable is the brand label that is applied. One line requires 12 production workers, while both lines together can be operated by 18 workers because of the common processes. Workers on the line perform low-skilled, repetitive tasks.

The plant produces both the salt and the cans the salt is packaged in. The cans are essentially a cylinder with a top and a bottom; they are made of cardboard, except for a plastic pour spout in the top. The cylinder portion is formed from two sheets of chip board that are glued together and then rolled into a continuous tube. The glue not only binds the material, it also provides a moisture barrier. The tube is cut in a two-step process. It is first cut into long sections, and those sections are then cut into can-size pieces. The top and bottom pieces for the cans are punched from a continuous strip of cardboard. The separate pieces move along conveyor belts to the lines where the components are assembled into cans and glued. The cans are then filled with salt and the pour spout is added. Finally, the cans are loaded onto pallets and placed into inventory, ready to be shipped to distributors.

Quality

Quality is checked at several points in the production process. Initially, the salt is checked for purity when it is obtained from the wells, Iodine and an anti-caking compound are added to the salt, and their levels are verified using chemical analysis. Crystal size is important. In order to achieve the desired size and to remove lumps, the salt is forced through a scraping screen, which can cause very fine pieces of metal to mix with the salt. However, these pieces are effectively removed by magnets that are placed at appropriate points in the process. If, for any reason, the salt is judged to be contaminated, it is diverted to a nonfood product.

Checking the quality of the cans is done primarily by visual inspection, including verifying the assembly operation is correct, checking filed cans for correct weight, inspecting cans to see that labels are labels are properly aligned, and checking to see that plastic pour spouts are correctly attached.

The equipment on the production line is sensitive to misshapen or damaged cans, and frequently jams, cussing production delays. This greatly reduces the chance of a defective can getting through the process, but it reduces productivity, and the salt in the defective cans must be scrapped. The cost of quality is fairly high, owing to the amount of product that is scrapped, the large number of inspectors, and the extensive laboratory testing that is needed.

Production Planning and Inventory

The plant can sell all of the salt it produces. The job of the production

Equipment Maintenance and Repair

The equipment is 1950s vintage, and it requires a fair amount of maintenance to keep it in good working order. Even so, breakdowns occur as parts wear out. The plant has its own tool shop where skilled workers repair parts or make new parts because replacement parts are no longer available for the old equipment.

4. Where would you place salt production in the product-process spectrum?

Want to see the full answer?

Check out a sample textbook solution

Chapter 6 Solutions

OPERATIONS MANAGEMENT LOOSELEAF W/ CONN

- As part of your new role, as a strategy consultant and member of the steering committee, discuss what logistics and transportation strategies you will execute to achieve operational efficiencies and facilitate economic growth in SA. The committee would like to have a implementable strategic transport and logistics plan to realise the roadmap vision based on the subsection numbering given below: QUESTION ONE Marks 5 Introduction: Must include an overview and history of South Africa's Road, rail and freight transport network. 1.1 Assess what led to such logistical inefficiencies/collapse of a previously world class freight network 10 1.2 What are the current freight and logistic challenges on the road network 10 1.3 Discuss key relevant financials of infrastructure, industries and revenue resulting in this logistics crisis. 15 1.4 Discuss how the key stakeholder partnerships - current and future are critical to government and business as part of the overall intermodal transport strategy.…arrow_forwardWhat are the current freight and logistic challenges on the road network Discuss key relevant financials of infrastructure, industries and revenue resulting in this logistics crisis. 10 15arrow_forward1.5 If you examine the freight supply and value chain, what transport and infrastructure strategies and 25 plans need to be implemented to improve operation efficiencies and reduce costs. 5 1.6 15 Discuss how implementation of a strategic intermodal transport plan can further unlock and improve South Africa's GDP and international recognition.arrow_forward

- A certain business process is no longer providing the desired benefits, therefore it needs to be re-designed through a project. You have to: Choose the business process to re-design and specify the reason why it is no longer satisfactory. Ask ChatGPT (or a similar generative AI; specify name and version) to create a Project Charter for the process redesign project. Modify and refine the response provided by the AI tool ensuring it complies with the instructor’s lesson, with particular focus on the project goals, project objectives, and deliverables (remember: project objectives must be SMART!). Your work must be delivered in the following format: a)Describe the business process to re-design (example: “The process of hiring and integrating new employees into the Sales Administration department”. Do not exceed 20 words) b)Specify the reason to re-design the business process which is already in place (describe the reason why the current process is no longer satisfactory, for…arrow_forwardThe demand for subassembly S is 100 units in week 7. Each unit of S requires 1 unit of T and 2 units of U. Each unit of T requires 1 unit of V, 2 units of W, and 1 unit of X. Finally, each unit of U requires 2 units of Y and 3 units of Z. One firm manufactures all items. It takes 2 weeks to make S, 1 week to make T, 2 weeks to make U, 2 weeks to make V, 3 weeks to make W, 1 week to make X, 2 weeks to make Y, and 1 week to make Z. Click the icon to view the product structure and the time-phased product structure. Click the icon to view the on-hand inventory. Construct a net material requirements plan using on-hand inventory (enter your responses as whole numbers). Item 1 2 3 Week 4 Lead Time 5 6 7 (weeks) S Gross req On hand Net req Order receipt Order release T Gross req On hand Net req Order receipt Order release Gross rea 100 100arrow_forwardIt is January 1 of year 0, and Merck is trying to determine whether to continue development of a newdrug. The following information is relevant. You can assume that all cash flows occur at the ends of therespective years.■ Clinical trials (the trials where the drug is tested on humans) are equally likely to be completed in year1 or 2.■ There is an 80% chance that clinical trials will succeed. If these trials fail, the FDA will not allow thedrug to be marketed.■ The cost of clinical trials is assumed to follow a triangular distribution with best case $100 million,most likely case $150 million, and worst case $250 million. Clinical trial costs are incurred at the end ofthe year clinical trials are completed.■ If clinical trials succeed, the drug will be sold for five years, earning a profit of $6 per unit sold.■ If clinical trials succeed, a plant will be built during the same year trials are completed. The cost of theplant is assumed to follow a triangular distribution with best case $1…arrow_forward

- 1) Under “Costs of Quality”, costs associated with quality can be classified into four categories: appraisal, prevention, internal failures, and external failures. The costs of quality for Corley Motors Logistics is given in the table. Cost Elements Amount Checking outbound boxes for errors $31,000 Quality planning $10,625 Downtime due to conveyor/computer problems $342,125 Incoming product inspection $21,000 Customer complaint rework $33,000 Correcting erroneous orders before shipping $36,550 Quality training of associates $25,925 Correction of typographical errors--pick tickets $11,475 a) Classify the quality cost elements given in the table into the different quality cost categories (prevention, appraisal, internal failure, external failure). b) Total the quality costs in each of the different quality cost categories (prevention, appraisal, internal failure, external failure). c) Using a) and b), suggest which areas…arrow_forwardNote: In chapter 9, section 9.4 of the Stevenson text, the costs of quality are covered; chapter 9 Stevenson lecture power point slide 7 touches upon this topic; see lecture video, 3.55 mins to 4.54 mins. 2) The production process at Hansa Ceylon Coffee fills boxes with dark arabica coffee. The data for the fill weight (in ounces) of eight samples are presented below. A sample size of six was used. The firm’s operations analyst wants to construct X-bar and R-charts to monitor the filling process. Sample Sample Mean Sample Range 1 15.80 0.42 2 16.10 0.38 3 16.02 0.08 4 15.95 0.15 5 16.12 0.42 6 16.18 0.23 7 15.87 0.36 8 16.20 0.40 a) Calculate the upper and lower control limits for the X-bar chart. b) Calculate the upper and lower control limits for the R chart. c) Is the process under control? Why or why not? Note: In chapter 10, section 10.3 of the Stevenson text, control charts for variables are…arrow_forwardDo the inherent differences between private and public sector objectives—profit versus publicgood—render private sector category management practices unsuitable for public sectorpurchasing, where open tendering is the norm?You have now undergone the Category Management classes and your superiors have requestedfor your input on how to integrate some of the learnings into the public sector policy. Discuss and elaborate what are the activities and governance you would introduce in yourrecommendations without violating the principle of transparency and accountability withinyour organisation. This is based on Singapore context. Pls provide a draft with explanation, examples and useful links for learning purposes. Citations will be good too. This is a module in SUSS called category management and supplier evaluationarrow_forward

- Travelling and working internationally can lead to a life of adventure and unique career experiences. For businesses, selecting the right candidates to take on foreign assignments can propel, delay, or deny the success of the international ventures. As an international manager, identify key competencies you would look for in choosing expatriates. What might be some of their concerns in taking on overseas assignments? What are some best practices in supporting expats during and after their assignments?arrow_forwardTravelling and working internationally can lead to a life of adventure and unique career experiences. For businesses, selecting the right candidates to take on foreign assignments can propel, delay, or deny the success of the international ventures. As an international manager, identify key competencies you would look for in choosing expatriates. What might be some of their concerns in taking on overseas assignments? What are some best practices in supporting expats during and after their assignments?arrow_forwardI need answer typing clear urjent no chatgpt used pls i will give 5 Upvotes.arrow_forward

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,