MORTON SALT

Introduction

Morton Salt is a subsidiary of Morton International, a manufacturer of specialty chemicals, air bags, and salt products. The Morton salt-processing facility in Silver Springs, New York, between Buffalo and Rochester, is one of six similar Morton salt-processing facilities in the United States. The Silver Springs plant employs about 200 people, ranging from unskilled to skilled. It produces salt products for water conditioning, grocery, industrial, and agricultural markets. The grocery business consists of 26-oz. round cans of iodized salt. Although the grocery business represents a relatively small portion of the total output (approximately 15 percent), it is the most profitable.

Salt production

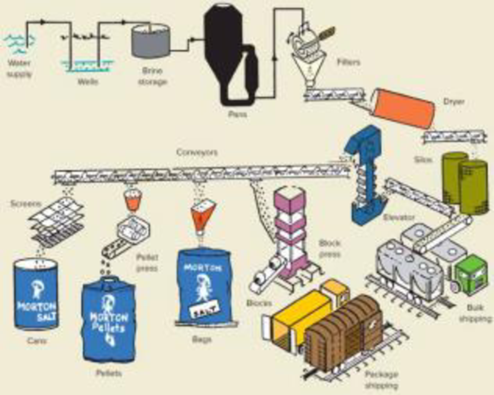

The basic raw material, salt, is obtained by injecting water into salt caverns that are located some 2,400 feet below the surface. There, the salt deposits dissolve in the water. The resulting brine is pumped to the surface where it is converted into salt crystals. The brine is boiled, and much of the liquid evaporates, leaving salt crystals and some residual moisture, which is removed in a drying process. This process is run continuously for about six weeks at a time. Initially, salt is produced at the rate of 45 tons per hour. But the rate of output decreases due to scale buildup, so that by the sixth week, output is only 75 percent of the initial rate. At that point, the process is halted to perform maintenance on the equipment and remove the scale, after which salt production resumes.

The salt is stored in silos until it is needed for production, or it is needed for production, or it is shipped in bulk to industrial customers. Conveyors move the salt to each of the four dedicated production areas, one of which is round can production (see diagram.). The discussion here focuses exclusively on round can production.

Round Can Production

Annual round can production averages roughly 3.8 million cans. Approximately 70 percent of the output is for the Morton label, and the rest is for private label. There are two parallel, high-speed production lines. The lines share common processes at the beginning of the lines, and then branch out into two identical lines. Each line is capable of producing 9,600 cans per hour (160 cans per minute). The equipment is not flexible, so the production rate is fixed. The operations are completely standardized; the only variable is the brand label that is applied. One line requires 12 production workers, while both lines together can be operated by 18 workers because of the common processes. Workers on the line perform low-skilled, repetitive tasks.

The plant produces both the salt and the cans the salt is packaged in. The cans are essentially a cylinder with a top and a bottom; they are made of cardboard, except for a plastic pour spout in the top. The cylinder portion is formed from two sheets of chip board that are glued together and then rolled into a continuous tube. The glue not only binds the material, it also provides a moisture barrier. The tube is cut in a two-step process. It is first cut into long sections, and those sections are then cut into can-size pieces. The top and bottom pieces for the cans are punched from a continuous strip of cardboard. The separate pieces move along conveyor belts to the lines where the components are assembled into cans and glued. The cans are then filled with salt and the pour spout is added. Finally, the cans are loaded onto pallets and placed into inventory, ready to be shipped to distributors.

Quality

Quality is checked at several points in the production process. Initially, the salt is checked for purity when it is obtained from the wells, Iodine and an anti-caking compound are added to the salt, and their levels are verified using chemical analysis. Crystal size is important. In order to achieve the desired size and to remove lumps, the salt is forced through a scraping screen, which can cause very fine pieces of metal to mix with the salt. However, these pieces are effectively removed by magnets that are placed at appropriate points in the process. If, for any reason, the salt is judged to be contaminated, it is diverted to a nonfood product.

Checking the quality of the cans is done primarily by visual inspection, including verifying the assembly operation is correct, checking filed cans for correct weight, inspecting cans to see that labels are labels are properly aligned, and checking to see that plastic pour spouts are correctly attached.

The equipment on the production line is sensitive to misshapen or damaged cans, and frequently jams, cussing production delays. This greatly reduces the chance of a defective can getting through the process, but it reduces productivity, and the salt in the defective cans must be scrapped. The cost of quality is fairly high, owing to the amount of product that is scrapped, the large number of inspectors, and the extensive laboratory testing that is needed.

Production Planning and Inventory

The plant can sell all of the salt it produces. The job of the production

Equipment Maintenance and Repair

The equipment is 1950s vintage, and it requires a fair amount of maintenance to keep it in good working order. Even so, breakdowns occur as parts wear out. The plant has its own tool shop where skilled workers repair parts or make new parts because replacement parts are no longer available for the old equipment.

3. What are some of the possible reasons why the company continues to use the old processing equipment instead of buying new, more modern equipment?

Want to see the full answer?

Check out a sample textbook solution

Chapter 6 Solutions

Operations Management

- How can a local tourism and hospitality company successfully enter international markets?arrow_forwardHow was Circuit City Company collapsed? And what was the sequence of time and events or problems? How to solve the issues, and could you help identify positions or titles. Sanitize all names and use only fictitious data. What is synthesize the qualitative research methodology of Case Study research? Please give some examples. How to use the practical of Lean Six Sigma to develop a business-facing DMAIC-based case studyarrow_forwardBUSINESS MODEL CANVAS: U.S ARMY key partners: Key activities: Key Resources: Value Propositions: Buy-in & Support: Deployment: Benficiaries: Mission budget/cost: Mission Achievement/ Impact factors: Please at least 4 for each categoryarrow_forward

- how you would best conduct a performance evaluation meeting with a subordinate (where an employee would receive their performance evaluation from their supervisor). Importantly, detail how a supervisor can best gain the concurrence from an employee on the evaluation itself, and to ensure that the employee’s performance will be modified as a result of appraisal meeting.arrow_forwardI need answer typing clear urjent no chatgpt used pls i will give 5 Upvotes.arrow_forwardassume that you are police commander which leads and supervises the department’s internal affairs division. Your goal is to reduce civilian complainants against personnel in the department. Using what you have learned and at least three scholarly sources, document two changes you see the department can implement, whether it be training, planning, mitigating, and resolving, to improve police/community relations.arrow_forward

- Ness Engineering is a private limited company mainly engaged in the continuous production and assembly of domestic products. The annual turnover is $900,000,000. The largest area of expenditure is raw materials and components where the annual spend is approximately $450,000,000. The Managing Director, Bill, considers that profit margins are too small and has asked you to suggest how profitability might be increased. Bill suggests that this might be done by appointing additional sales staff and by an advertising campaign, which would, hopefully, increase turnover and thereby reduce overhead cost per item. You find that purchasing is little more than a post-office function. Specifications are received from the design or user departments and sent either to supplies designated by the directors or to the supplier providing the cheapest quotation. The company does, in fact, deal with many suppliers and issues many orders for low-cost items. All purchasing is done by manual means. None of the…arrow_forwardThe oasis outpost of Abu Ilan, in the heart of the Negev desert, has a population of 20 Bedouin tribesmen and 20 Farima tribesmen. El Kamin, a nearby oasis, has a population of 32 Bedouins and 8 Farima. A lost Israeli soldier, accidentally separated from his army unit, is wandering through the desert and arrives at the edge of one of the oases. The soldier has no idea which oasis he has found, but the first person he spots at a distance is a Bedouin. 1. What is the probability that he wandered into Abu Ilan? 2. What is the probability that he is in El Kamin?arrow_forward2-22 The lost Israeli soldier mentioned in Problem 2-21 decides to rest for a few minutes before entering the desert oasis he has just found. Closing his eyes, he dozes off for 15 minutes, wakes, and walks toward the center of the oasis. The first person he spots this time he again recognizes as a Bedouin. What is the posterior probability that he is in El Kamin?*Note* 2-21 The oasis outpost of Abu Ilan, in the heart of the Negev desert, has a population of 20 Bedouin tribesmen and 20 Farima tribesmen. El Kamin, a nearby oasis, has a population of 32 Bedouins and 8 Farima. A lost Israeli soldier, accidentally separated from his army unit, is wandering through the desert and arrives at the edge of one of the oases. The soldier has no idea which oasis he has found, but the first person he spots at a distance is a Bedouin. What is the probability that he has wandered into Abu Ilan? What is the probability that he is in El Kamin?arrow_forward

- Hello, please make an excel of this. Show all the cells thanks. some replied with a paper answer thank you I just cant understand the way the did it. Can someone show me all screenshots o fthis problem solved and in excel? i need to solver too for the constraints. I seen multiple times across other platforms that one of the chairs optimal solutions is 0 but they both have to be higher than 1 The Heinrich Company manufactures two types of plastic hangerracks (Foldaways and Straightaways) especially suited for mountingnear clothes dryers. Because permanent press clothing must be hungon hangers immediately after removal from the dryer, these items havebeen especially popular. However, there is some concern that thePreppie movement (popularized by its own handbook) will extinguishpolyester clothing; Heinrich is terribly interested in doing the best withthe resources it has while its products are still in demand. The firsttype of hanger rack, the Foldaway, requires 10 ounces of…arrow_forwardReview the Profit Ratio by Product chart again. What information is uncovered when the data is less aggregated than the data in Profit Ratio by Category chart?arrow_forwardWhat is the correlation between Measure A and Measure B in this example?arrow_forward

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,