Concept explainers

(a)

The work-done in open die forging of cylinder for no friction between the flat dies and the specimen.

(a)

Explanation of Solution

Given:

The initial thickness of the specimen is

The initial radius of the specimen is

The friction coefficient is

Formula used:

The expression for the flow stress is given as,

Here,

The expression for the true strain is given as,

Here,

The expression for the final radius by equating the volume is given as,

The expression for the forging force is given as,

Here,

The expression for the average pressure is given as,

The expression for final height for

The expression for final height for

The expression forfinal height for

The expression for final height for

The expression for final height for

Calculation:

For

The final height can be calculated as,

The final radius can be calculated as,

The true strain can be calculated as,

The flow stress can be calculated as,

Refer to table 2.2 “Typical values of strength coefficient

The average pressure can be calculated as,

The forging force can be calculated as,

For

The final height can be calculated as,

The final radius can be calculated as,

The true strain can be calculated as,

The flow stress can be calculated as,

Refer to table 2.2 “Typical values of strength coefficient

The average pressure can be calculated as,

The forging force can be calculated as,

For

The final height can be calculated as,

The final radius can be calculated as,

The true strain can be calculated as,

The flow stress can be calculated as,

Refer to table 2.2 “Typical values of strength coefficient

The average pressure can be calculated as,

The forging force can be calculated as,

For

The final height can be calculated as,

The final radius can be calculated as,

The true strain can be calculated as,

The flow stress can be calculated as,

Refer to table 2.2 “Typical values of strength coefficient

The average pressure can be calculated as,

The forging force can be calculated as,

For

The final height can be calculated as,

The final radius can be calculated as,

The true strain can be calculated as,

The flow stress can be calculated as,

Refer to table 2.2 “Typical values of strength coefficient

The average pressure can be calculated as,

The forging force can be calculated as,

For

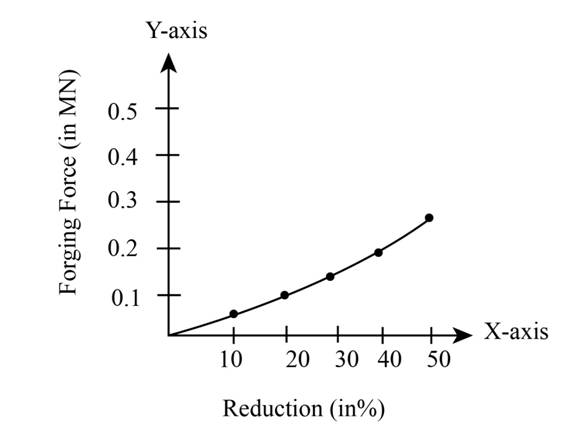

| Reduction (in ) | Forging force (in ) | Area under curve (in ) |

| 2.1635 |

Work done can be calculated by calculating the sum of area under the curve.

The figure (1) shows the curve between the forging force and reduction in height,

Figure (1)

(b)

The work-done in open die forging of cylinder for

(b)

Explanation of Solution

Given:

The initial thickness of the specimen is

The initial radius of the specimen is

The friction coefficient is

Formula used:

The expression for the flow stress is given as,

Here,

The expression for the true strain is given as,

Here,

The expression for the final radius by equating the volume is given as,

The expression for the forging force is given as,

Here,

The expression for the average pressure is given as,

The expression for final height for

The expression for final height for

The expression forfinal height for

The expression for final height for

The expression for final height for

Calculation:

For

The final height can be calculated as,

The final radius can be calculated as,

The true strain can be calculated as,

The flow stress can be calculated as,

Refer to table 2.2 “Typical values of strength coefficient

The average pressure can be calculated as,

The forging force can be calculated as,

For

The final height can be calculated as,

The final radius can be calculated as,

The true strain can be calculated as,

The flow stress can be calculated as,

Refer to table 2.2 “Typical values of strength coefficient

The average pressure can be calculated as,

The forging force can be calculated as,

For

The final height can be calculated as,

The final radius can be calculated as,

The true strain can be calculated as,

The flow stress can be calculated as,

Refer to table 2.2 “Typical values of strength coefficient

The average pressure can be calculated as,

The forging force can be calculated as,

For

The final height can be calculated as,

The final radius can be calculated as,

The true strain can be calculated as,

The flow stress can be calculated as,

Refer to table 2.2 “Typical values of strength coefficient

The average pressure can be calculated as,

The forging force can be calculated as,

For

The final height can be calculated as,

The final radius can be calculated as,

The true strain can be calculated as,

The flow stress can be calculated as,

Refer to table 2.2 “Typical values of strength coefficient

The average pressure can be calculated as,

The forging force can be calculated as,

For

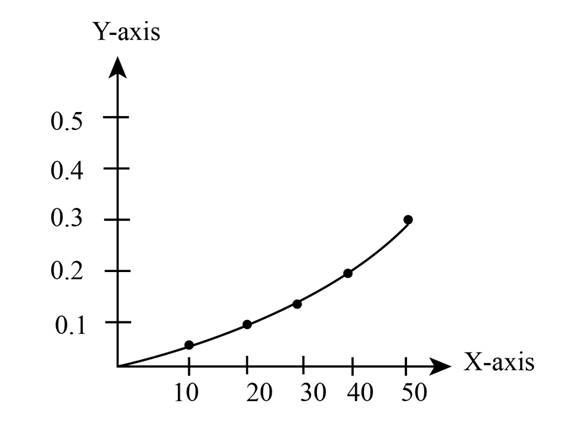

| Reduction (in ) | Forging force (in ) | Area under curve (in ) |

Work done can be calculated by calculating the sum of area under the curve.

The figure (2) shows the curve between the forging force and reduction in height,

Figure (2)

Want to see more full solutions like this?

Chapter 6 Solutions

Manufacturing Processes for Engineering Materials (6th Edition)

- CORRECT AND DETAILED HANDWRITTEN SOLUTION WITH FBD ONLY. I WILL UPVOTE THANK YOU. CORRECT ANSWER IS ALREADY PROVIDED. 13: A cantilever beam is of length 1.5 m,loaded by a concentrated load P at its tip as shown inFig. 8-18(a), and is of circular cross section (R = 100 mm),having two symmetrically placed longitudinal holes asindicated. The material is titanium alloy, having anallowable working stress in bending of 600 MPa.Determine the maximum allowable value of the verticalforce P. ANS: P = 236,589.076 N = 236.589 kNarrow_forwardCORRECT AND DETAILED HANDWRITTEN SOLUTION WITH FBD ONLY. I WILL UPVOTE THANK YOU. CORRECT ANSWER IS ALREADY PROVIDED. 15: Consider a beam having an I-type cross section as shown in Fig. 8-45. Ashearing force V of 150 kN acts over the section. Determine the maximum and minimumvalues of the shearing stress in the vertical web of the section.ANS: fv(max) = 44.048 MPa ; fv(min) = 33.202 MPaarrow_forwardCORRECT AND DETAILED HANDWRITTEN SOLUTION WITH FBD ONLY. I WILL UPVOTE THANK YOU. CORRECT ANSWER IS ALREADY PROVIDED. 12: A steel cantilever beam 16 ft 8 in in length is subjected to a concentrated load of 320 lb acting at the freeend of the bar. A commercially available rolled steel section, designated as W12x32, is used for the beam. Assume that the total depth of the beam is 12 in, and the neutral axis of the section is in the middle. Determine the maximum tensile and compressive stresses. (Properties of commercially available rolled steel section provided in the table. Z = section modulus). ANS: σT = σC = 1,572.482 lb/in2arrow_forward

- CORRECT AND DETAILED HANDWRITTEN SOLUTION WITH FBD ONLY. I WILL UPVOTE THANK YOU. CORRECT ANSWER IS ALREADY PROVIDED. 14: Two ½-in x 8-in cover plates are welded to two channels 10 in high to formthe cross section of the beam shown in Fig. 8-59. Loads are in a vertical plane and bendingtakes place about a horizontal axis. The moment of inertia of each channel about ahorizontal axis through the centroid is 78.5 in4. If the maximum allowable elastic bendingstress is 18,000 lb/in2, determine the maximum bending moment that may be developedin the beam.ANS: 1,236,000 lb-in.arrow_forwardCORRECT AND DETAILED HANDWRITTEN SOLUTION WITH FBD ONLY. I WILL UPVOTE THANK YOU. CORRECT ANSWER IS ALREADY PROVIDED. 11: A beam of circular cross section is 7 in in diameter. It is simply supported at each end and loaded by twoconcentrated loads of 20,000 lb each, applied 12 in from the ends of the beam. Determine the maximum bending stressin the beam. ANS: σ = 7,127.172 lb/in2arrow_forwardusing the theorem of three moments, find all the reactions and supportsarrow_forward

- (An ellipsoidal trapping region for the Lorenz equations) Show that there is a certain ellipsoidal region E of the form rx2 + σy2 + σ(z − 2r)2 ≤ C such that all trajectories of the Lorenz equations eventually enter E and stay in there forever. For a much stiffer challenge, try to obtain the smallest possible value of C with this property.arrow_forwardA) In a factory, an s-type pitot tube was used to calculate the velocity of dry air for a point inside a stack. Calculate the velocity at that point (ft/sec) using following conditions: ● • • Pressure = 30.23 ± 0.01 in Hg (ambient) Pitot tube coefficient = 0.847 ± 0.03 Temperature = 122 ± 0.1 F (stack) Temperature = 71.2 ± 0.1 F (ambient) AP = 0.324 ± 0.008 in H2O (pitot tube) • AP = 0.891 ± 0.002 in H2O (stack) B) Find the dominant error(s) when determining precision for the problem. C) For part A, what is the precision in ft/sec for the velocity?arrow_forwardQ1/ For what value of x do the power series converge: 8 (-1)n-1. x2n-1 2n-1 x3 x5 = X n=1 3 Q2/ Find the Interval of convergence and Radius of convergence of the series: 8 n Σ 3+1 n=1 (x)"arrow_forward

- Example-1: l D A uniform rotor of length 0.6 m and diameter 0.4 m is made of steel (density 7810 kg/m³) is supported by identical short bearings of stiffness 1 MN/m in the horizontal and vertical directions. If the distance between the bearings is 0.7 m, determine the natural frequencies and plot whirl speed map. Solution: Barrow_forwardfind the laplace transform for the flowing function 2(1-e) Ans. F(s)=- S 12) k 0 Ans. F(s)= k s(1+e) 0 a 2a 3a 4a 13) 2+ Ans. F(s)= 1 s(1+e") 3 14) f(t)=1, 0arrow_forwardFind the solution of the following Differential Equations Using Laplace Transforms 1) 4y+2y=0. y(0)=2. y'(0)=0. 2) y+w²y=0, (0)=A, y'(0)=B. 3) +2y-8y 0. y(0)=1. y'(0)-8. 4)-2-3y=0, y(0)=1. y'(0)=7. 5) y-ky'=0, y(0)=2, y'(0)=k. 6) y+ky'-2k²y=0, y(0)=2, y'(0) = 2k. 7) '+4y=0, y(0)=2.8 8) y+y=17 sin(21), y(0)=-1. 9) y-y-6y=0, y(0)=6, y'(0)=13. 10) y=0. y(0)=4, y' (0)=0. 11) -4y+4y-0, y(0)=2.1. y'(0)=3.9 12) y+2y'+2y=0, y(0)=1, y'(0)=-3. 13) +7y+12y=21e". y(0)=3.5. y'(0)=-10. 14) "+9y=10e". y(0)=0, y'(0)=0. 15) +3y+2.25y=91' +64. y(0)=1. y'(0) = 31.5 16) -6y+5y-29 cos(2t). y(0)=3.2, y'(0)=6.2 17) y+2y+2y=0, y(0)=0. y'(0)=1. 18) y+2y+17y=0, y(0)=0. y'(0)=12. 19) y"-4y+5y=0, y(0)=1, y'(0)=2. 20) 9y-6y+y=0, (0)-3, y'(0)=1. 21) -2y+10y=0, y(0)=3, y'(0)=3. 22) 4y-4y+37y=0, y(0)=3. y'(0)=1.5 23) 4y-8y+5y=0, y(0)=0, y'(0)=1. 24) ++1.25y-0, y(0)=1, y'(0)=-0.5 25) y 2 cos(r). y(0)=2. y'(0) = 0. 26) -4y+3y-0, y(0)=3, y(0) 7. 27) y+2y+y=e y(0)=0. y'(0)=0. 28) y+2y-3y=10sinh(27), y(0)=0. y'(0)=4. 29)…arrow_forwardarrow_back_iosSEE MORE QUESTIONSarrow_forward_ios

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY