Concept explainers

(a)

The temperature of the steam after the flashing process and the power output from the turbine if the pressure of the steam at the exit of flash chamber is

(a)

Explanation of Solution

Given:

The inlet mass

The inlet pressure

The inlet temperature

The mass flow rate

The pressure at exit

The moisture content

Calculation:

Initially find out the properties of the geothermal water.

At state 1:

The geothermal water is extracted at the state of saturated liquid at the temperature of

The enthalpy at state 1 is as follows.

Refer Table A-4, “Saturated water-Temperature table”

The enthalpy

Refer Table A-1, “Molar mass, gas constant, and critical-point properties”.

At state 2:

The exit pressure of the flash chamber is

The geothermal steam is flashed at constant enthalpy. The exit steam of the flash chamber is at the quality of

Here, the fluid enthalpy is

Substitute

Refer Table A-5, “Saturated water-Pressure table”.

Obtain the following corresponding to the pressure of

At state 3:

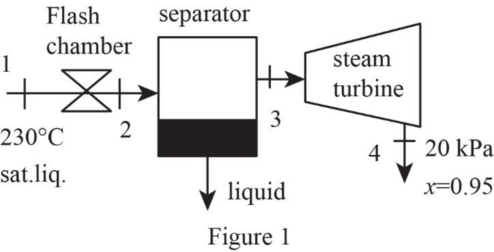

There is no pressure drop in the separator. The separator separates vapor and liquid form the flashed steam, and the separated vapor alone sent to the turbine.

The enthalpy

Refer Table A-5, “Saturated water-Pressure table”.

The enthalpy

At state 4:

The steam is at the state of saturated mixture at the pressure of

The quality at state 4 is as follows.

The enthalpy

Refer Table A-5, “Saturated water-Pressure table”.

Obtain the following corresponding to the pressure of

The temperature of the steam after flashing process is equal to the saturation temperature at the exit pressure of flash chamber i.e.

Refer Table A-5, “Saturated water-Pressure table”.

The temperature

Thus, the exit temperature of flash chamber is

Write the formula for mass flow rate of vapor at entering the turbine.

Substitute

Draw schematic diagram of single flash geothermal power plant as shown in Figure 1.

Write the general energy rate balance equation.

Here, the rate of total energy in is

Consider the system operates at steady state. Hence, the rate of change in net energy of the system becomes zero.

The Equation (I) is reduced as follows.

Refer Figure 1.

The flash chamber is nothing but the expansion valve. At expansion valve, the enthalpy kept constant.

Express the energy balance equation for the flash chamber.

Express the energy balance equation for the separator.

Express the energy balance equation for the turbine.

Substitute

Equation (III).

Thus, the power output turbine is

(b)

The temperature of the steam after the flashing process and the power output from the turbine if the pressure of the steam at the exit of flash chamber is

(b)

Explanation of Solution

Similarly for the pressure

At state 2:

The exit pressure of the flash chamber is

Refer Table A-5, “Saturated water-Pressure table”.

Obtain the following corresponding to the pressure of

At state 3:

There is no pressure drop in the separator. The separator separates vapor and liquid form the flashed steam, and the separated vapor alone sent to the turbine.

The enthalpy

Refer Table A-5, “Saturated water-Pressure table”.

The enthalpy

Calculation:

The temperature of the steam after flashing process is equal to the saturation temperature at the exit pressure of flash chamber i.e.

Refer Table A-5, “Saturated water-Pressure table”.

The temperature

Thus, the exit temperature of flash chamber is

Substitute

Substitute

Substitute

Equation (III).

Thus, the power output turbine is

(c)

The temperature of the steam after the flashing process and the power output from the turbine if the pressure of the steam at the exit of flash chamber is

(c)

Explanation of Solution

At state 2:

The exit pressure of the flash chamber is

Refer Table A-5, “Saturated water-Pressure table”.

Obtain the following corresponding to the pressure of

At state 3:

There is no pressure drop in the separator. The separator separates vapor and liquid form the flashed steam, and the separated vapor alone sent to the turbine.

The enthalpy

Refer Table A-5, “Saturated water-Pressure table”.

The enthalpy

The temperature of the steam after flashing process is equal to the saturation temperature at the exit pressure of flash chamber i.e.

Refer Table A-5, “Saturated water-Pressure table”.

The temperature

Thus, the exit temperature of flash chamber is

Substitute

Substitute

Substitute

Equation (III).

Thus, the power output turbine is

(d)

The temperature of the steam after the flashing process and the power output from the turbine if the pressure of the steam at the exit of flash chamber is

(d)

Explanation of Solution

At state 2:

The exit pressure of the flash chamber is

Refer Table A-5, “Saturated water-Pressure table”.

Obtain the following corresponding to the pressure of

At state 3:

There is no pressure drop in the separator. The separator separates vapor and liquid form the flashed steam, and the separated vapor alone sent to the turbine.

The enthalpy

Refer Table A-5, “Saturated water-Pressure table”.

The enthalpy

The temperature of the steam after flashing process is equal to the saturation temperature at the exit pressure of flash chamber i.e.

Refer Table A-5, “Saturated water-Pressure table”.

The temperature

Thus, the exit temperature of flash chamber is

Substitute

Substitute

Substitute

Equation (III).

Thus, the power output turbine is

Want to see more full solutions like this?

Chapter 6 Solutions

EBK FUNDAMENTALS OF THERMAL-FLUID SCIEN

- Consider the feedback controlled blending system shown below, which is designed to keep theoutlet concentration constant despite potential variations in the stream 1 composition. The density of all streamsis 920 kg/m3. At the nominal steady state, the flow rates of streams 1 and 2 are 950 and 425 kg/min,respectively, the liquid level in the tank is 1.3 m, the incoming mass fractions are x1 = 0.27, x2 = 0.54. Noticethe overflow line, indicating that the liquid level remains constant (i.e. any change in total inlet flow ratetranslates immediately to the same change in the outlet flow rate). You may assume the stream 1 flowrate andthe stream 2 composition are both constant. Use minutes as the time unit throughout this problem. Identify any controlled variable(s) (CVs), manipulated variable(s) (MVs),and disturbance variable(s) (DVs) in this problem. For each, explain how you know that’show it is classified.CVs: ___________, MVs: _____________, DVs: ______________ b) Draw a block diagram…arrow_forwardA heat transfer experiment is conducted on two identical spheres which are initially at the same temperature. The spheres are cooled by placing them in a channel. The fluid velocity in the channel is non-uniform, having a profile as shown. Which sphere cools off more rapidly? Explain. V 1arrow_forwardMy ID# 016948724 last 2 ID# 24 Last 3 ID# 724 Please help to find the correct answer for this problem using my ID# first write le line of action and then help me to find the forces {fx= , fy= mz= and for the last find the moment of inertial about the show x and y axes please show how to solve step by steparrow_forward

- My ID# 016948724 last 2 ID# 24 Last 3 ID# 724 Please help to find the correct answer for this problem using my ID# first write le line of action and then help me to find the forces and the tension {fx= , fy= mz=arrow_forwardMy ID# 016948724 last 2 ID# 24 Last 3 ID# 724 Please help to find the correct answer for this problem using my ID# first write le line of action and then help me to find the forces {fx= , fy= mz=arrow_forwardmy ID is 016948724 Last 2 ID# 24 Last 3 ID# 724 please help me to solve this problem step by step show me how to solve first wirte the line actions and then find the forces {fx=, fy=, mz= and for the last step find the support reactions and find forcesarrow_forward

- Uppgift 1 (9p) 3 m 3 m 3 m 3 m H G F 3 m ↑ Dy D B AAY 30° 8 kN Ay Fackverket i figuren ovan är belastat med en punktlast. Bestäm normalkraften i stängerna BC, BG och FG.arrow_forwardThe cardiovascular countercurrent heat exchnager mechanism is to warm venous blood from 28 degrees C to 35 degrees C at a mass flow rate of 2 g/s. The artery inflow temp is 37 degrees C at a mass flow rate of 5 g/s. The average diameter of the vein is 5 cm and the overall heat transfer coefficient is 125 W/m^2*K. Determine the overall blood vessel length needed too warm the venous blood to 35 degrees C if the specific heat of both arterial and venous blood is constant and equal to 3475 J/kg*K.arrow_forwardThe forces Qy=12 kNQy=12kN and Qz=16 kNQz=16kN act on the profile at the shear center C. Calculate: a) Shear flow at point B (2 points)b) Shear stress at point D (3 points)arrow_forward

- Consider the feedback controlled blending system shown below, which is designed to keep theoutlet concentration constant despite potential variations in the stream 1 composition. The density of all streamsis 920 kg/m3. At the nominal steady state, the flow rates of streams 1 and 2 are 950 and 425 kg/min,respectively, the liquid level in the tank is 1.3 m, the incoming mass fractions are x1 = 0.27, x2 = 0.54. Noticethe overflow line, indicating that the liquid level remains constant (i.e. any change in total inlet flow ratetranslates immediately to the same change in the outlet flow rate). You may assume the stream 1 flowrate andthe stream 2 composition are both constant. Use minutes as the time unit throughout this problem. d) Derive the first order process and disturbance transfer functions;Gp= Kp/(tou*s+1) and Gd=Kd/(tou*s+1) and calculate and list the values and units of the parameters. e) Using the given information, write the general forms of Gm, GIP, and Gv below(in terms of…arrow_forwarda) Briefly explain what ratio control is. Give an example of a common chemical engineering situation in whichratio control would be useful and for that example state exactly how ratio control works (what would bemeasured, what is set, and how the controller logic works).b) Briefly explain what cascade control is. Give an example of a common chemical engineering situation inwhich cascade control would be useful and for that example state exactly how cascade control works (whatwould be measured, what is set, and how the controller logic works).arrow_forwardDetermine the reaction force acting on the beam AB, given F = 680 N. 5 4 4 m 3 3 A B 30° 3 m F (N)arrow_forward

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY