Thermodynamics: An Engineering Approach

9th Edition

ISBN: 9781260048766

Author: CENGEL

Publisher: MCG

expand_more

expand_more

format_list_bulleted

Textbook Question

Chapter 5.5, Problem 142RP

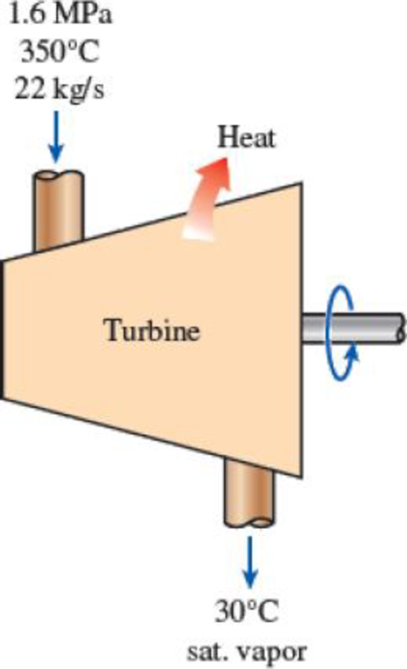

A steam turbine operates with 1.6 MPa and 350°C steam at its inlet and saturated vapor at 30°C at its exit. The mass flow rate of the steam is 22 kg/s, and the turbine produces 12,350 kW of power. Determine the rate at which heat is lost through the casing of this turbine.

FIGURE P5–142

Expert Solution & Answer

Want to see the full answer?

Check out a sample textbook solution

Students have asked these similar questions

Steam enters a two-stage adiabatic turbine at 8 MPa and 500°C. It expands in the first stage to a state of 2 MPa and 350°C. Steam is then reheated at constant pressure to a temperature of 500°C before it is routed to the second stage, where it exits at 30 kPa and a quality of 97 percent. The work output of the turbine is 5 MW. Assuming the surroundings to be at 25°C, determine the reversible power output and the rate of exergy destruction within this turbine.

Steam enters the condenser of a steam power plant at 50 kPa and a quality of 85 percent with a mass flow rate of 400 kg/min. It is to be cooled by water from a nearby river by circulating the water through the tubes within the condenser. To prevent thermal pollution, the river water is not allowed to experience a temperature rise above 20°C. If the steam is to leave the condenser as saturated liquid at 50 kPa, determine the mass flow rate of the cooling water required.

3. Steam enters an adiabatic turbine steadily at 8Mpa and 500C at a rate of Skg/s and leaves at

30kpa. If the power output of the turbine 2.5MW determine the temperature of the steam at

the turbine exit. Neglect kinetic energy changes.

Chapter 5 Solutions

Thermodynamics: An Engineering Approach

Ch. 5.5 - Name four physical quantities that are conserved...Ch. 5.5 - Define mass and volume flow rates. How are they...Ch. 5.5 - Does the amount of mass entering a control volume...Ch. 5.5 - Consider a device with one inlet and one outlet....Ch. 5.5 - The ventilating fan of the bathroom of a building...Ch. 5.5 - Air enters a 16-cm-diameter pipe steadily at 200...Ch. 5.5 - A steam pipe is to transport 200 lbm/s of steam at...Ch. 5.5 - A garden hose attached with a nozzle is used to...Ch. 5.5 - A steady-flow compressor is used to compress...Ch. 5.5 - Air enters the 1-m2 inlet of an aircraft engine at...

Ch. 5.5 - A 2-m3 rigid tank initially contains air whose...Ch. 5.5 - Air enters a nozzle steadily at 2.21 kg/m3 and 40...Ch. 5.5 - A spherical hot-air balloon is initially filled...Ch. 5.5 - Water enters the constant 130-mm inside-diameter...Ch. 5.5 - A desktop computer is to be cooled by a fan whose...Ch. 5.5 - A hair dryer is basically a duct of constant...Ch. 5.5 - Refrigerant-134a enters a 28-cm-diameter pipe...Ch. 5.5 - What are the different mechanisms for transferring...Ch. 5.5 - How do the energies of a flowing fluid and a fluid...Ch. 5.5 - An air compressor compresses 6 L of air at 120 kPa...Ch. 5.5 - A house is maintained at 1 atm and 24C, and warm...Ch. 5.5 - Refrigerant-134a enters the compressor of a...Ch. 5.5 - Steam is leaving a pressure cooker whose operating...Ch. 5.5 - How is a steady-flow system characterized?Ch. 5.5 - Can a steady-flow system involve boundary work?Ch. 5.5 - A diffuser is an adiabatic device that decreases...Ch. 5.5 - The kinetic energy of a fluid increases as it is...Ch. 5.5 - The stators in a gas turbine are designed to...Ch. 5.5 - The diffuser in a jet engine is designed to...Ch. 5.5 - Air enters a nozzle steadily at 50 psia, 140F, and...Ch. 5.5 - Air at 600 kPa and 500 K enters an adiabatic...Ch. 5.5 - Carbon dioxide enters an adiabatic nozzle steadily...Ch. 5.5 - Steam enters a nozzle at 400C and 800 kPa with a...Ch. 5.5 - Air at 80 kPa and 127C enters an adiabatic...Ch. 5.5 - Air at 13 psia and 65F enters an adiabatic...Ch. 5.5 - Refrigerant-134a at 700 kPa and 120C enters an...Ch. 5.5 - Refrigerant-134a enters a diffuser steadily as...Ch. 5.5 - Air at 80 kPa, 27C, and 220 m/s enters a diffuser...Ch. 5.5 - Air enters an adiabatic nozzle steadily at 300...Ch. 5.5 - Consider an adiabatic turbine operating steadily....Ch. 5.5 - Prob. 42PCh. 5.5 - Somebody proposes the following system to cool a...Ch. 5.5 - Air is expanded from 1000 kPa and 600C at the...Ch. 5.5 - Prob. 45PCh. 5.5 - Refrigerant-134a enters a compressor at 100 kPa...Ch. 5.5 - Refrigerant-134a enters a compressor at 180 kPa as...Ch. 5.5 - Steam flows steadily through an adiabatic turbine....Ch. 5.5 - Steam flows steadily through a turbine at a rate...Ch. 5.5 - Steam enters an adiabatic turbine at 8 MPa and...Ch. 5.5 - An adiabatic air compressor compresses 10 L/s of...Ch. 5.5 - Carbon dioxide enters an adiabatic compressor at...Ch. 5.5 - Steam flows steadily into a turbine with a mass...Ch. 5.5 - Air is compressed by an adiabatic compressor from...Ch. 5.5 - Air enters the compressor of a gas-turbine plant...Ch. 5.5 - A portion of the steam passing through a steam...Ch. 5.5 - Why are throttling devices commonly used in...Ch. 5.5 - Would you expect the temperature of air to drop as...Ch. 5.5 - During a throttling process, the temperature of a...Ch. 5.5 - Someone claims, based on temperature measurements,...Ch. 5.5 - Refrigerant-134a is throttled from the saturated...Ch. 5.5 - A saturated liquidvapor mixture of water, called...Ch. 5.5 - Prob. 64PCh. 5.5 - A well-insulated valve is used to throttle steam...Ch. 5.5 - Refrigerant-134a enters the expansion valve of a...Ch. 5.5 - Prob. 68PCh. 5.5 - Prob. 69PCh. 5.5 - Consider a steady-flow heat exchanger involving...Ch. 5.5 - Prob. 71PCh. 5.5 - Refrigerant-134a at 700 kPa, 70C, and 8 kg/min is...Ch. 5.5 - Hot and cold streams of a fluid are mixed in a...Ch. 5.5 - A hot-water stream at 80C enters a mixing chamber...Ch. 5.5 - Water at 80F and 20 psia is heated in a chamber by...Ch. 5.5 - An adiabatic open feedwater heater in an electric...Ch. 5.5 - Cold water (cp = 4.18 kJ/kgC) leading to a shower...Ch. 5.5 - Steam is to be condensed on the shell side of a...Ch. 5.5 - Air (cp = 1.005 kJ/kgC) is to be preheated by hot...Ch. 5.5 - An open feedwater heater heats the feedwater by...Ch. 5.5 - Refrigerant-134a at 1 MPa and 90C is to be cooled...Ch. 5.5 - The evaporator of a refrigeration cycle is...Ch. 5.5 - An air-conditioning system involves the mixing of...Ch. 5.5 - A well-insulated shell-and-tube heat exchanger is...Ch. 5.5 - Steam is to be condensed in the condenser of a...Ch. 5.5 - Steam is to be condensed in the condenser of a...Ch. 5.5 - Two streams of water are mixed in an insulated...Ch. 5.5 - Two mass streams of the same ideal gas are mixed...Ch. 5.5 - Water is heated in an insulated, constant-diameter...Ch. 5.5 - A 110-volt electrical heater is used to warm 0.3...Ch. 5.5 - The ducts of an air heating system pass through an...Ch. 5.5 - The fan on a personal computer draws 0.3 ft3/s of...Ch. 5.5 - Saturated liquid water is heated in a steady-flow...Ch. 5.5 - Water enters the tubes of a cold plate at 70F with...Ch. 5.5 - Prob. 96PCh. 5.5 - A computer cooled by a fan contains eight PCBs,...Ch. 5.5 - A desktop computer is to be cooled by a fan. The...Ch. 5.5 - Prob. 99PCh. 5.5 - A 4-m 5-m 6-m room is to be heated by an...Ch. 5.5 - A house has an electric heating system that...Ch. 5.5 - A long roll of 2-m-wide and 0.5-cm-thick 1-Mn...Ch. 5.5 - Prob. 103PCh. 5.5 - Prob. 104PCh. 5.5 - Argon steadily flows into a constant-pressure...Ch. 5.5 - Steam enters a long, horizontal pipe with an inlet...Ch. 5.5 - Refrigerant-134a enters the condenser of a...Ch. 5.5 - A hair dryer is basically a duct in which a few...Ch. 5.5 - A hair dryer is basically a duct in which a few...Ch. 5.5 - Air enters the duct of an air-conditioning system...Ch. 5.5 - An insulated rigid tank is initially evacuated. A...Ch. 5.5 - A rigid, insulated tank that is initially...Ch. 5.5 - Prob. 115PCh. 5.5 - A 2-m3 rigid tank initially contains air at 100...Ch. 5.5 - A 0.2-m3 rigid tank equipped with a pressure...Ch. 5.5 - Prob. 118PCh. 5.5 - An insulated 40-ft3 rigid tank contains air at 50...Ch. 5.5 - A 4-L pressure cooker has an operating pressure of...Ch. 5.5 - An air-conditioning system is to be filled from a...Ch. 5.5 - Oxygen is supplied to a medical facility from ten...Ch. 5.5 - A 0.05-m3 rigid tank initially contains...Ch. 5.5 - A 0.12-m3 rigid tank contains saturated...Ch. 5.5 - A 0.3-m3 rigid tank is filled with saturated...Ch. 5.5 - The air-release flap on a hot-air balloon is used...Ch. 5.5 - Prob. 127PCh. 5.5 - An insulated 0.15-m3 tank contains helium at 3 MPa...Ch. 5.5 - A vertical pistoncylinder device initially...Ch. 5.5 - A vertical piston-cylinder device initially...Ch. 5.5 - A pistoncylinder device initially contains 0.6 kg...Ch. 5.5 - The weighted piston of the device shown in Fig....Ch. 5.5 - Prob. 136RPCh. 5.5 - Prob. 137RPCh. 5.5 - Prob. 138RPCh. 5.5 - Air at 4.18 kg/m3 enters a nozzle that has an...Ch. 5.5 - Prob. 140RPCh. 5.5 - An air compressor compresses 15 L/s of air at 120...Ch. 5.5 - A steam turbine operates with 1.6 MPa and 350C...Ch. 5.5 - Refrigerant-134a enters an adiabatic compressor at...Ch. 5.5 - Prob. 144RPCh. 5.5 - Prob. 145RPCh. 5.5 - Prob. 146RPCh. 5.5 - Prob. 147RPCh. 5.5 - Steam enters a nozzle with a low velocity at 150C...Ch. 5.5 - Prob. 149RPCh. 5.5 - Prob. 150RPCh. 5.5 - Prob. 151RPCh. 5.5 - Prob. 152RPCh. 5.5 - Prob. 153RPCh. 5.5 - Cold water enters a steam generator at 20C and...Ch. 5.5 - An ideal gas expands in an adiabatic turbine from...Ch. 5.5 - Determine the power input for a compressor that...Ch. 5.5 - Prob. 157RPCh. 5.5 - Prob. 158RPCh. 5.5 - Prob. 159RPCh. 5.5 - Prob. 160RPCh. 5.5 - In a dairy plant, milk at 4C is pasteurized...Ch. 5.5 - Prob. 162RPCh. 5.5 - Prob. 163RPCh. 5.5 - Prob. 164RPCh. 5.5 - Prob. 165RPCh. 5.5 - Prob. 166RPCh. 5.5 - The average atmospheric pressure in Spokane,...Ch. 5.5 - The ventilating fan of the bathroom of a building...Ch. 5.5 - Prob. 169RPCh. 5.5 - Determine the rate of sensible heat loss from a...Ch. 5.5 - Prob. 171RPCh. 5.5 - An air-conditioning system requires airflow at the...Ch. 5.5 - A building with an internal volume of 400 m3 is to...Ch. 5.5 - The maximum flow rate of standard shower heads is...Ch. 5.5 - Prob. 176RPCh. 5.5 - Prob. 177RPCh. 5.5 - Steam enters a turbine steadily at 7 MPa and 600C...Ch. 5.5 - Reconsider Prob. 5178. Using appropriate software,...Ch. 5.5 - Prob. 180RPCh. 5.5 - A liquid R-134a bottle has an internal volume of...Ch. 5.5 - A pistoncylinder device initially contains 2 kg of...Ch. 5.5 - A pistoncylinder device initially contains 1.2 kg...Ch. 5.5 - A pressure cooker is a pot that cooks food much...Ch. 5.5 - A tank with an internal volume of 1 m3 contains...Ch. 5.5 - In a single-flash geothermal power plant,...Ch. 5.5 - An adiabatic air compressor is to be powered by a...Ch. 5.5 - The turbocharger of an internal combustion engine...Ch. 5.5 - Prob. 189RPCh. 5.5 - Consider an evacuated rigid bottle of volume V...Ch. 5.5 - An adiabatic heat exchanger is used to heat cold...Ch. 5.5 - A heat exchanger is used to heat cold water at 15C...Ch. 5.5 - An adiabatic heat exchanger is used to heat cold...Ch. 5.5 - In a shower, cold water at 10C flowing at a rate...Ch. 5.5 - Prob. 195FEPCh. 5.5 - Prob. 196FEPCh. 5.5 - Hot combustion gases (assumed to have the...Ch. 5.5 - Steam expands in a turbine from 4 MPa and 500C to...Ch. 5.5 - Steam is compressed by an adiabatic compressor...Ch. 5.5 - Refrigerant-134a is compressed by a compressor...Ch. 5.5 - Refrigerant-134a at 1.4 MPa and 70C is throttled...Ch. 5.5 - Prob. 202FEPCh. 5.5 - Prob. 203FEPCh. 5.5 - Air at 27C and 5 atm is throttled by a valve to 1...Ch. 5.5 - Steam at 1 MPa and 300C is throttled adiabatically...Ch. 5.5 - Air is to be heated steadily by an 8-kW electric...Ch. 5.5 - Saturated water vapor at 40C is to be condensed as...

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Steam enters an adiabatic turbine at 8 MPa, 550°C, and 57 (m/s and leaves at 60 kPa, 150°C, and 140 m/s. If the power output of the turbine is 5 MW, determine (1) the mass flow rate of the steam flowing through the turbine and (2) the isentropic efficiency of the turbine. 3:25arrow_forwardSteam at 400°C and 800 kPa enters a nozzle with a velocity of 10 m/s and leaves at 300°C and 200 kPa while losing heat at a rate of 25 kW. For an inlet area of 800 cm2, determine the velocity and volumetric flow rate of steam at the nozzle outlet.arrow_forwardRefrigerant-134a enters the compressor of a refrigeration system as saturated vapor at 0.14 MPa and leaves as superheated vapor at 0.8 MPa and 60°C at a rate of 0.06 kg/s. Determine the rates of energy transfers by mass into and out of the compressor. Assume the kinetic and potential energies to be negligible. The enthalpies of refrigerant-134a at the inlet and the exit are 239.19 kJ/kg and 296.82 kJ/kg, respectively. The rate of energy transfer by mass into the compressor is The rate of energy transfer by mass out of the compressor is kW. kW.arrow_forward

- Steam enters a turbine steadily at a flow rate of 1 kg/s at 7 MPa and 500 degrees and exits as saturated steam at 40 kPa. If there is a heat loss of 10 kW from the turbine, what will be the power produced by the turbine?arrow_forwardRefrigerant 134a enters a compressor with a mass flow rate of 15 kg/s with a velocity of 10 m/s. The refrigerant enters the compressor as a saturated vapor at 10°C and leaves the compressor at 1400 kPa with an enthalpy of 281.39 kJ/kg with a negligible velocity. The rate of work done on the refrigerant is measured to be 380 kW. If the elevation change between the compressor inlet and exit is negligible, determine the rate of heat transfer associated with this process, in kW.arrow_forwardA turbine operates with superheated steam entering at 900°F and 1,100 psia with a mass flow rate of 70 lbm/s. The exhaust pressure is 5 psia and the turbine efficiency is 0.80. Determine the power output of the turbine in kW.arrow_forward

- 5arrow_forwardLiquid water at 120 kPa enters a 7-kW pump where its pressure is raised to 5 MPa. If the elevation difference between the exit and the inlet levels is 10 m, determine the highest mass flow rate of liquid water this pump can handle. Neglect the kinetic energy change of water, and take the specific volume of water to be 0.001 m3 /kg.arrow_forwardA steam turbine operates adiabatically at a power level of 3500 kW. Steam enters the turbine at 2400 kPa and 500°C and exhausts from the turbine as wet steam with a quality of 97% at 20 kPa. Determine the turbine's efficiency and estimated lost work.arrow_forward

- A compressor operating with 7.7 kg/s water vapour with a compression ratio (P2/P1) equal to 3.0 is cooled down by means of a cooling system which extracts 74 kJ/kg of heat (per unit mass of fluid) from the device. The steam enters the compressor as saturated vapor at 1.5 MPa and leaves it at 773 K. Calculate the power required if the compressor operates with an efficiency of 0.94. Give your answer in MW to 1 decimal place.arrow_forwardL Steam flows steadily into a turbine with a mass flow rate of 20 kg/s at 6 MPa and 600°C with a velocity of 120 m/s. The steam exits the turbine at 0.5 MPa and 200°C with a negligible velocity. Determine the power produced by the turbine and the work done per unit mass.arrow_forwardQ: Five hundred kilograms per hour of steam drives a turbine. The steam enters the turbine at 44 atm and 450°C at a linear velocity of 60 m/s and leaves at a point 5 m below the turbine inlet at atmospheric pressure and a velocity of 360 m/s. The turbine delivers shaft work at a rate of 70 kW, and the heat loss from the turbine is estimated to be 10ʻ kcal/h. Calculate the specific enthalpy change associated with the process.arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press

Elements Of ElectromagneticsMechanical EngineeringISBN:9780190698614Author:Sadiku, Matthew N. O.Publisher:Oxford University Press Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON

Mechanics of Materials (10th Edition)Mechanical EngineeringISBN:9780134319650Author:Russell C. HibbelerPublisher:PEARSON Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education

Thermodynamics: An Engineering ApproachMechanical EngineeringISBN:9781259822674Author:Yunus A. Cengel Dr., Michael A. BolesPublisher:McGraw-Hill Education Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY

Control Systems EngineeringMechanical EngineeringISBN:9781118170519Author:Norman S. NisePublisher:WILEY Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning

Mechanics of Materials (MindTap Course List)Mechanical EngineeringISBN:9781337093347Author:Barry J. Goodno, James M. GerePublisher:Cengage Learning Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Engineering Mechanics: StaticsMechanical EngineeringISBN:9781118807330Author:James L. Meriam, L. G. Kraige, J. N. BoltonPublisher:WILEY

Elements Of Electromagnetics

Mechanical Engineering

ISBN:9780190698614

Author:Sadiku, Matthew N. O.

Publisher:Oxford University Press

Mechanics of Materials (10th Edition)

Mechanical Engineering

ISBN:9780134319650

Author:Russell C. Hibbeler

Publisher:PEARSON

Thermodynamics: An Engineering Approach

Mechanical Engineering

ISBN:9781259822674

Author:Yunus A. Cengel Dr., Michael A. Boles

Publisher:McGraw-Hill Education

Control Systems Engineering

Mechanical Engineering

ISBN:9781118170519

Author:Norman S. Nise

Publisher:WILEY

Mechanics of Materials (MindTap Course List)

Mechanical Engineering

ISBN:9781337093347

Author:Barry J. Goodno, James M. Gere

Publisher:Cengage Learning

Engineering Mechanics: Statics

Mechanical Engineering

ISBN:9781118807330

Author:James L. Meriam, L. G. Kraige, J. N. Bolton

Publisher:WILEY

Power Plant Explained | Working Principles; Author: RealPars;https://www.youtube.com/watch?v=HGVDu1z5YQ8;License: Standard YouTube License, CC-BY