Understanding Motor Controls

4th Edition

ISBN: 9781337798686

Author: Stephen L. Herman

Publisher: Delmar Cengage Learning

expand_more

expand_more

format_list_bulleted

Concept explainers

Textbook Question

Chapter 54, Problem 8RQ

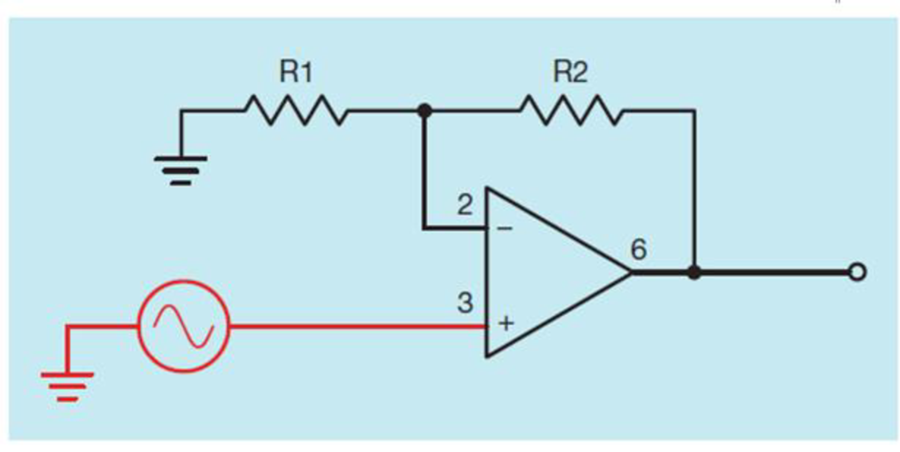

Refer to Figure 54–8. If resistor R1 is 200 ohms and resistor R2 is 10 kilohms, what is the gain of the amplifier?

Figure 54–8 Noninverting amplifier connection.

Expert Solution & Answer

Want to see the full answer?

Check out a sample textbook solution

Students have asked these similar questions

3

N2=28

P(diametral pitch)=8 for all gears

Coupled to 25 hp motor

N3=34

Full depth spur gears with pressure angle=20°

N₂=2000 rpm

(1) Compute the circular pitch, the center-to-center distance, and base circle radii.

(2) Draw the free body diagram of gear 3 and show all the forces and the torque.

(3) In mounting gears, the center-to-center distance was reduced by 0.1 inch.

Calculate the new values of center-to-center distance, pressure angle, base circle radii,

and pitch circle diameters.

(4)What is the new tangential and radial forces for gear 3?

(5) Under the new center to center distance, is the contact ratio (mc) increasing or

decreasing?

2. A flat belt drive consists of two 4-ft diameter cast-iron pulleys spaced 16 ft apart.

A power of 60 hp is transmitted by a pulley whose speed is 380 rev/min. Use a

service factor (Ks) pf 1.1 and a design factor 1.0. The width of the polyamide A-3

belt is 6 in. Use CD=1. Answer the following questions.

(1) What is the total length of the belt according to the given geometry?

(2) Find the centrifugal force (Fc) applied to the belt.

(3) What is the transmitted torque through the pulley system given 60hp?

(4) Using the allowable tension, find the force (F₁) on the tight side. What is the

tension at the loose side (F2) and the initial tension (F.)?

(5) Using the forces, estimate the developed friction coefficient (f)

(6) Based on the forces and the given rotational speed, rate the pulley set. In other

words, what is the horse power that can be transmitted by the pulley system?

(7) To reduce the applied tension on the tight side, the friction coefficient is

increased to 0.75. Find out the…

The tooth numbers for the gear train illustrated are N₂ = 24, N3 = 18, №4 = 30, №6 = 36, and

N₁ = 54. Gear 7 is fixed. If shaft b is turned through 5 revolutions, how many turns will shaft a make?

a

5

[6]

b

Chapter 54 Solutions

Understanding Motor Controls

Ch. 54 - Prob. 1RQCh. 54 - Prob. 2RQCh. 54 - Prob. 3RQCh. 54 - Prob. 4RQCh. 54 - Prob. 5RQCh. 54 - Prob. 6RQCh. 54 - Name two effects of negative feedback.Ch. 54 - Refer to Figure 548. If resistor R1 is 200 ohms...Ch. 54 - Refer to Figure 54–9. If resistor R1 is 470 ohms...Ch. 54 - What is the purpose of the hysteresis loop when...

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- Please do not use any AI tools to solve this question. I need a fully manual, step-by-step solution with clear explanations, as if it were done by a human tutor. No AI-generated responses, please.arrow_forwardPlease do not use any AI tools to solve this question. I need a fully manual, step-by-step solution with clear explanations, as if it were done by a human tutor. No AI-generated responses, please.arrow_forwardCE-112 please solve this problem step by step and give me the correct answerarrow_forward

- CE-112 please solve this problem step by step and give me the correct asnwerarrow_forwardthis is an old practice exam, the answer is Ax = -4, Ay = -12,Az = 32.5, Bx= 34, Bz = 5, By = 0 but how?arrow_forwardThis is an old practice exam, the answer is Ax = Az = 0, Ay = 2000, TDE = 4750, Cx = 2000, Cy = 2000, Cz = -800 but how?arrow_forward

- this is an old practice exam, the answer is Fmin = 290.5lb but howarrow_forwardThis is an exam review question. The answer is Pmin = 622.9 lb but whyarrow_forwardPlease do not use any AI tools to solve this question. I need a fully manual, step-by-step solution with clear explanations, as if it were done by a human tutor. No AI-generated responses, please.arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Understanding Motor ControlsMechanical EngineeringISBN:9781337798686Author:Stephen L. HermanPublisher:Delmar Cengage Learning

Understanding Motor ControlsMechanical EngineeringISBN:9781337798686Author:Stephen L. HermanPublisher:Delmar Cengage Learning Refrigeration and Air Conditioning Technology (Mi...Mechanical EngineeringISBN:9781305578296Author:John Tomczyk, Eugene Silberstein, Bill Whitman, Bill JohnsonPublisher:Cengage Learning

Refrigeration and Air Conditioning Technology (Mi...Mechanical EngineeringISBN:9781305578296Author:John Tomczyk, Eugene Silberstein, Bill Whitman, Bill JohnsonPublisher:Cengage Learning Electrical Transformers and Rotating MachinesMechanical EngineeringISBN:9781305494817Author:Stephen L. HermanPublisher:Cengage Learning

Electrical Transformers and Rotating MachinesMechanical EngineeringISBN:9781305494817Author:Stephen L. HermanPublisher:Cengage Learning Automotive Technology: A Systems Approach (MindTa...Mechanical EngineeringISBN:9781133612315Author:Jack Erjavec, Rob ThompsonPublisher:Cengage Learning

Automotive Technology: A Systems Approach (MindTa...Mechanical EngineeringISBN:9781133612315Author:Jack Erjavec, Rob ThompsonPublisher:Cengage Learning Automotive TechnologyMechanical EngineeringISBN:9781337794213Author:ERJAVEC, Jack.Publisher:Cengage,

Automotive TechnologyMechanical EngineeringISBN:9781337794213Author:ERJAVEC, Jack.Publisher:Cengage,

Understanding Motor Controls

Mechanical Engineering

ISBN:9781337798686

Author:Stephen L. Herman

Publisher:Delmar Cengage Learning

Refrigeration and Air Conditioning Technology (Mi...

Mechanical Engineering

ISBN:9781305578296

Author:John Tomczyk, Eugene Silberstein, Bill Whitman, Bill Johnson

Publisher:Cengage Learning

Electrical Transformers and Rotating Machines

Mechanical Engineering

ISBN:9781305494817

Author:Stephen L. Herman

Publisher:Cengage Learning

Automotive Technology: A Systems Approach (MindTa...

Mechanical Engineering

ISBN:9781133612315

Author:Jack Erjavec, Rob Thompson

Publisher:Cengage Learning

Automotive Technology

Mechanical Engineering

ISBN:9781337794213

Author:ERJAVEC, Jack.

Publisher:Cengage,

Ch 2 - 2.2.2 Forced Undamped Oscillation; Author: Benjamin Drew;https://www.youtube.com/watch?v=6Tb7Rx-bCWE;License: Standard youtube license