Engineering Mechanics: Statics

13th Edition

ISBN: 9780132915540

Author: Russell C. Hibbeler

Publisher: Prentice Hall

expand_more

expand_more

format_list_bulleted

Concept explainers

Textbook Question

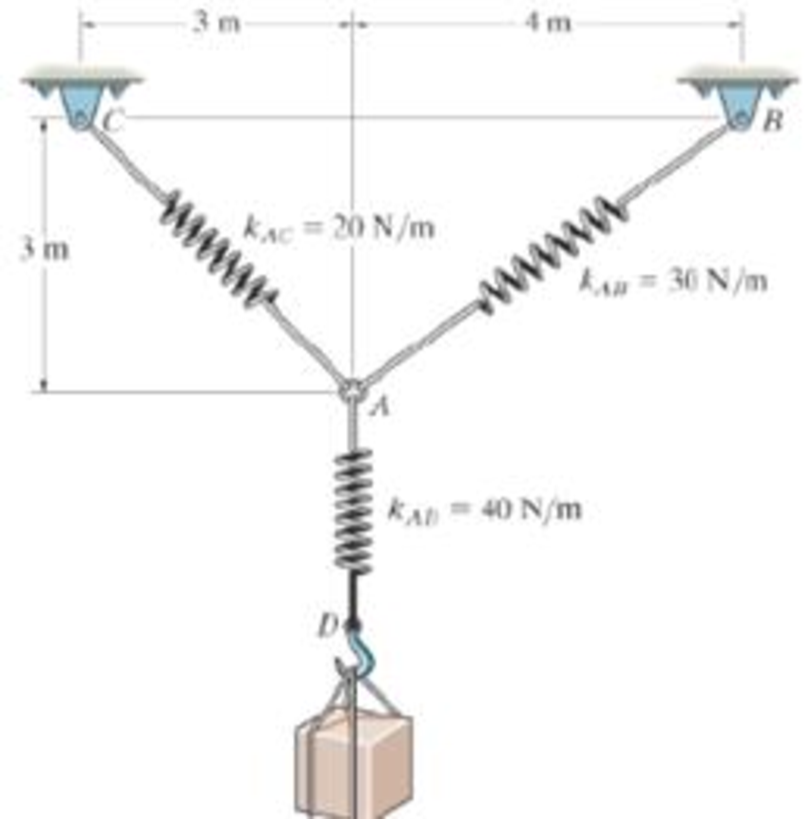

Chapter 3.3, Problem 19P

If the block is held in the equilibrium position shown, determine the mass of the block at D.

Expert Solution & Answer

Learn your wayIncludes step-by-step video

schedule07:36

Students have asked these similar questions

(◉

Home - my.uah.edu

Homework#5

MasteringEngineering Mastering X +

8 https://session.engineering-mastering.pearson.com/myct/itemView?assignmentProblemID=18992148&offset=next

CHAPTER 14: Kinetics of a Particle: Conservation of Energy

Qu.4 The spring has a stiffness k = 200 N/m and an unstretched length of 0.5 m. If it is attached to the 3-

kg smooth collar and the collar is released from rest at A, determine the speed of the collar when it reaches B. Neglect the size of the collar.please show all work step by step

Qu. 2 The 100-kg crate is subjected to the action of two forces. If it is originally at rest, determine the distance it slides in order to attain a speed of 6 m/s. The coefficient of kinetic friction between the crate

and the surface is uk = 0.2.

i need to show all work step by step problems

Chapter 3 Solutions

Engineering Mechanics: Statics

Ch. 3.3 - Determine the force in each supporting cable.Ch. 3.3 - Determine the shortest cable ABC that can be used...Ch. 3.3 - Neglect the size of the pulley.Ch. 3.3 - Determine the unstretched length of the spring.Ch. 3.3 - If the mass of cylinder C is 40 kg, determine the...Ch. 3.3 - Also, find the angle .Ch. 3.3 - Determine the magnitudes of F1 and F2 for...Ch. 3.3 - Determine the magnitude of F1 and its angle for...Ch. 3.3 - Determine the force in each of the cables AB and...Ch. 3.3 - Prob. 4P

Ch. 3.3 - Prob. 5PCh. 3.3 - Prob. 6PCh. 3.3 - Prob. 7PCh. 3.3 - Prob. 8PCh. 3.3 - Determine the maximum weight of the flowerpot that...Ch. 3.3 - Prob. 10PCh. 3.3 - Prob. 11PCh. 3.3 - Prob. 12PCh. 3.3 - Prob. 13PCh. 3.3 - Prob. 14PCh. 3.3 - Prob. 15PCh. 3.3 - Prob. 16PCh. 3.3 - Note that s = 0 when the cylinders are removed.Ch. 3.3 - The springs are shown in the equilibrium position.Ch. 3.3 - If the block is held in the equilibrium position...Ch. 3.3 - Determine the horizontal force F applied to the...Ch. 3.3 - Determine the displacement d of the cord from the...Ch. 3.3 - If the spring has an unstretched length of 2 ft,...Ch. 3.3 - Cord AB is 2 ft long. Take k = 50 lb/ft.Ch. 3.3 - Prob. 24PCh. 3.3 - Prob. 25PCh. 3.3 - Prob. 26PCh. 3.3 - Prob. 27PCh. 3.3 - Determine the tension developed in each cord...Ch. 3.3 - Determine the maximum mass of the lamp that the...Ch. 3.3 - Prob. 30PCh. 3.3 - Prob. 31PCh. 3.3 - Prob. 32PCh. 3.3 - Prob. 33PCh. 3.3 - Prob. 34PCh. 3.3 - Determine the position x and the tension developed...Ch. 3.3 - Determine the position x and the tension in the...Ch. 3.3 - If the cable can be attached at either points A...Ch. 3.3 - Prob. 38PCh. 3.3 - The cord is fixed to a pin at A and passes over...Ch. 3.3 - Prob. 40PCh. 3.3 - Take F = 300 N and d = 1 m.Ch. 3.3 - If a force of F = 100 N is applied horizontally to...Ch. 3.3 - Establish appropriate dimensions and use an...Ch. 3.3 - If the maximum tension that can be supported by...Ch. 3.3 - If the angle between AB and BC is 30, determine...Ch. 3.3 - If the distance BC is 1.5 m, and AB can support a...Ch. 3.4 - Determine the magnitude of forces F1, F2, F3, so...Ch. 3.4 - Determine the tension developed in cables AB, AC,...Ch. 3.4 - Determine the tension developed in cables AB, AC,...Ch. 3.4 - F310. Determine the tension developed in cables...Ch. 3.4 - Determine the tension in these wires.Ch. 3.4 - Prob. 43PCh. 3.4 - If cable AB is subjected to a tension of 700 N,...Ch. 3.4 - Determine the magnitudes of F1, F2, and F3 for...Ch. 3.4 - If the bucket and its contents have a total weight...Ch. 3.4 - Each spring has on unstretched length of 2 m and a...Ch. 3.4 - Prob. 48PCh. 3.4 - Prob. 49PCh. 3.4 - Prob. 50PCh. 3.4 - Prob. 51PCh. 3.4 - Prob. 52PCh. 3.4 - Prob. 53PCh. 3.4 - Determine the tens on developed in cables AB and...Ch. 3.4 - Also, what is the force developed along strut AD?Ch. 3.4 - Prob. 56PCh. 3.4 - Prob. 57PCh. 3.4 - Determine the tension developed in each cable for...Ch. 3.4 - Determine the maximum weight of the crate that can...Ch. 3.4 - Determine the force in each chain for equilibrium....Ch. 3.4 - If cable AD is tightened by a turnbuckle and...Ch. 3.4 - If cable AD is tightened by a turnbuckle and...Ch. 3.4 - Prob. 63PCh. 3.4 - Prob. 64PCh. 3.4 - Prob. 65PCh. 3.4 - Prob. 66PCh. 3.4 - Prob. 67PCh. 3.4 - If the bolt exerts a force of 50 lb on the pipe in...Ch. 3.4 - Determine the magnitude of the applied vertical...Ch. 3.4 - Prob. 70RPCh. 3.4 - Prob. 71RPCh. 3.4 - Prob. 72RPCh. 3.4 - Prob. 73RPCh. 3.4 - Also, what is the force in cord AB? Hint: use the...Ch. 3.4 - Prob. 75RPCh. 3.4 - Determine the force in each cable needed to...Ch. 3.4 - Prob. 77RP

Additional Engineering Textbook Solutions

Find more solutions based on key concepts

Porter’s competitive forces model: The model is used to provide a general view about the firms, the competitors...

Management Information Systems: Managing The Digital Firm (16th Edition)

A(n) _____ is a set of well-defined steps for performing a task or solving a problem.

Starting Out With Visual Basic (8th Edition)

Describe how the average of a collection of numbers can be computed more rapidly with a multiprocessor machine ...

Computer Science: An Overview (13th Edition) (What's New in Computer Science)

Identify and correct the errors in each of the following code segments assume that all variables have been prop...

Java How to Program, Early Objects (11th Edition) (Deitel: How to Program)

Sales Tax Program Refactoring Programming Exercise #6 in Chapter 2 was the Sales Tax program. For that exercise...

Starting Out with Python (4th Edition)

In Exercises 61 through 66, rewrite the statements using augmented assignment operators. Assume that each varia...

Introduction To Programming Using Visual Basic (11th Edition)

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, mechanical-engineering and related others by exploring similar questions and additional content below.Similar questions

- (◉ Home - my.uah.edu Homework#5 MasteringEngineering Mastering X + 8 https://session.engineering-mastering.pearson.com/myct/itemView?offset=next&assignmentProblemID=18992146arrow_forward(read image)arrow_forward(◉ Home - my.uah.edu Homework#5 MasteringEngineering Mastering X + 8 https://session.engineering-mastering.pearson.com/myct/itemView?assignmentProblemID=18992147&offset=nextarrow_forward

- (◉ Home - my.uah.edu Homework#5 MasteringEngineering Mastering X + 8 https://session.engineering-mastering.pearson.com/myct/itemView?assignmentProblemID=18992144&offset=nextarrow_forwardCalculate the forces in members BC, BG & FG of the truss shown using the Method of Sections. For your answer, provide atruss diagram of the calculated member forces and indicate whether the member is in Tension (+) or Compression (-)arrow_forwardSelect the speed, feed and depth of the cut to turn wrought, low carbon steel (hardness of 200 BHN) on lathe with AISI tool material of HSS M2 or M3. (Hint: refer to Chapter 21 for recommended parameters).arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

International Edition---engineering Mechanics: St...Mechanical EngineeringISBN:9781305501607Author:Andrew Pytel And Jaan KiusalaasPublisher:CENGAGE L

International Edition---engineering Mechanics: St...Mechanical EngineeringISBN:9781305501607Author:Andrew Pytel And Jaan KiusalaasPublisher:CENGAGE L

International Edition---engineering Mechanics: St...

Mechanical Engineering

ISBN:9781305501607

Author:Andrew Pytel And Jaan Kiusalaas

Publisher:CENGAGE L

EVERYTHING on Axial Loading Normal Stress in 10 MINUTES - Mechanics of Materials; Author: Less Boring Lectures;https://www.youtube.com/watch?v=jQ-fNqZWrNg;License: Standard YouTube License, CC-BY