Concept explainers

Repeat Problem 19-7 using two different depths of untreated aggregate bases of 6 in. and 12 in. Highway contractors in your area can furnish rates for providing and properly laying an asphalt concrete surface and untreated granular base. Assume a structural coefficient of 0.12 for the base course. If these rates are available, determine the cost for constructing the different pavement designs if the highway section is 5 miles long and the lane width is 12 ft. Which design will you select for construction?

The cost for constructing the different pavement designs.

Answer to Problem 13P

Explanation of Solution

Given information:

Following is the given information:

Equivalent single axle load, ESAL =

CBR =

Subgrade resilient modulus =

Sub-base layer coefficient =

Granular base layer coefficient =

Elastic modulus of asphalt concrete =

mi = 1, Percentage of traffic on design lane =

SN = 4, reliability level =

and design serviceability loss =

Calculation:

We have the following formula for the calculation of truck factor:

Where, ESAL i= equivalent accumulated 18,000-lb (80-kN) single-axle load for the axle category i

fd= design lane factor,

G rn= growth factor for a given growth rate r and design period n

AADT i= first-year annual average daily traffic for axle category i

N i= number of axles on each vehicle in category i

F Ei= load equivalency factor for axle category i

Calculate ESAL for passenger car

We have the following formula for the calculation of design serviceability :

Substitute the values in the required equation.

Initial serviceability index,

Terminal serviceability index,

Let's determine the resilient modulus of subgrade:

The resilient modulus of subgrade is 1500 times CBR

The value of resilient modulus is given as follows:

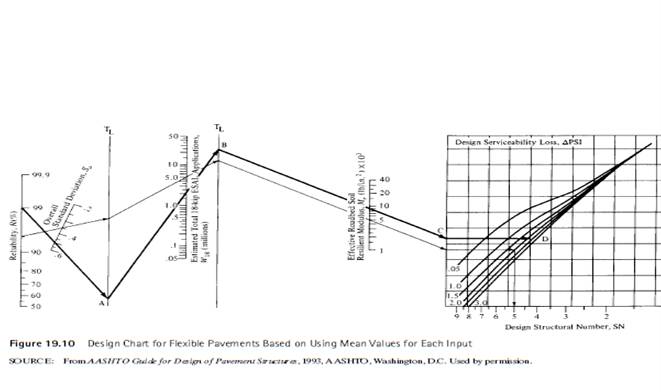

Now for the structural number, SN refer to figure 19.10

The reliability level is 90%. Starting from the point 90% in figure, extend this point to standard deviation 0.45. From standard deviation point, extend this line to line A as given in the figure.

From line A extend this line to

From ESAL extend this line to line B in the figure.

From line B extend this line to

From M rextend this line till it touches the graph. From that point, draw a horizontal line to touch the design serviceability loss, which is 2.

Extend a line vertically and take the structural number SN3reading, which is 2.5 and SN2is 2.3

Then from figure 19.6, for layer coefficient and the resilient modulus for base layer is

From figure 19.10, resilient modulus is

Refer figure 19.7 to determine layer coefficient

Now, considering the thickness aggregate base as 6 inches.

Calculate the minimum thickness.

The layer coefficient,

Substitute the values

Checking the values, we have

As the values match, thus the thickness of subgrade calculated is correct.

Calculate the required minimum thickness of base course D2is 6 inches.

Check whether the calculated thickness agrees with the calculated structural number using equation

Substituting the values, we have

Which is compatible with the structural number calculated already.

And implies that the thickness of the surface calculated is correct.

Now, the required minimum thickness of the sub-base course

By substituting the values, we have

Now, check if the calculated thickness agrees with the calculated structural number of using the following equation:

Substituting the values

Which is compatible with the structural number calculated already.

And implies that the thickness of the surface calculated is correct.

The thickness of surface 4.25 inches.

Now, considering the thickness aggregate base as 12 inches.

Calculate the minimum thickness.

Substitute the values, we have

Thus, the thickness of sub grade is 1.7 in.

Now, the thickness of the base course is given as follows:

Substitute the values.

Which is greater than 2.7, i.e., structural number.

Now, the required minimum thickness of the sub-base course

By substituting the values,

Now, check if the calculated thickness agrees with the calculated structural number of using the following equation

Substituting the values,

Which is compatible with the structural number calculated already.

And implies that the thickness of the surface calculated is correct.

Calculate construction cost for the highway considering thickness of base layer as 6 inches and 12 inches.

The cost is calculated by multiplying the measurement of road with the cost per rate.

Assume cost of surface layer as

For cost of base layer

For cost of sub-base layer

The construction cost of the highway is as follows:

Cost = L X B X t X C

For surface layer :

Substitute the values

5 miles is equal to 26400

For base layer :

Substitute the values

For sub-base layer :

Substitute the values

Now, calculate the total cost as follows:

The construction cost of the highway is as follows:

Cost = L X B X t X C

For surface layer :

Substitute the values

5 miles is equal to 26400

For base layer :

Substitute the values

For sub-base layer :

Substitute the values

Now, calculate the total cost as follows:

Conclusion:

Therefore, out of two cases the construction cost is

Want to see more full solutions like this?

- Sketch the effective stress profile for the silt layer to a depth of 5 meters for a uniform layer of silt having a depth to the water table of 4 m (choose several discrete points with depth and plot by hand). Use Bishop's definition of effective stress for the silt layer, assuming x =S.. Assume a value of G. = 2.65 and that the gravimetric water content of the silt below the water table is 20%. Use the SWRC for the silt from the figure below. Assume that the air pressure is equal to atmospheric pressure (i.e., zero). Consider variations in total unit weight with the degree of saturation in your calculations. 100000 a. 10000 Sand: a = 0.3 kPa, n = 3.0 Silt: a=0.05 kPa, n=2.5 0.01 kPa, n = 1.8 1000 Clay: Matric suction (kPa) 00 100 10 10 1 0.1 ° 20 60 80 40 Saturation (%) 100 10arrow_forwardYou are asked to design a two-story commercial building that has reinforced masonry shear walls as shown below. The height of the parapet above the roof is 2 feet. The walls are to be constructed of 8-inch CMU and are to be fully grouted. The building is assigned to SDC D, and therefore, the walls have to be special RM shear walls according to TMS 402. There are 6 shear walls to resist the lateral seismic force along one principal axis of the building and 4 shear walls along the other axis. The corner walls are flanged walls meeting the requirements in Sec. 5.2.3 of TMS 402-22. The columns carry only gravity loads and no lateral seismic forces. The floor and roof diaphragms are relatively flexible in out-of-plane bending compared to the in-plane flexural stiffness of the walls, so that you can ignore the coupling moments and shear forces exerted by the diaphragms on the walls. However, the in-plane stiffness of the diagrams is high so that their planar deformation can be ignored.…arrow_forwardDevelop a signal design and timing for the intersection shown in the figure below. In each case accommodate both vehicular and pedestrian movements. In general, use the following values for the problem: pedestrian walking speed = 1 [m/s], vehicle deceleration = 3 [m/s²], driver reaction time = 1.5 [s], length of vehicle 6 [m], and level grade = 0. If you need to assume = other variables and parameters to solve this problem clearly state that in your report and explain the reason. 250 1100 One-way Speed limit = 50 [km/h] Pedestrian = 15 per each crosswalk Crosswalk widths = 3 [m] Lane width = 4 [m] Saturation flow = 1800 [veh/h/lane] 1100 70 80 T 200 900arrow_forward

- A pre-timed four-phase signal has critical lane group flow rates for the first three phases of 260, 280, and 310 [veh/h] (saturation flow rates are 2000 [veh/h/In] for all phases). The lost time is known to be 5 seconds for each phase. If the cycle length is 90 seconds, what is the estimated effective green time of the fourth phase?arrow_forwarda. Assume a bus line with N stops, where the distance between stops is S. Free flow speed of the bus is v, with acceleration and deceleration, a. P passengers per stop are boarding and alighting, and the time needed for a passenger to board or alight is T seconds. What is the average speed of a bus? b. Following on part (a), assume the origins of passengers are spread uniformly along the bus route. The destination of all passengers is the last stop. The walking speed of passengers is u. Determine the average travel time (walking + in-vehicle) of passengers. c. Simplify the above equation when N is large enough (approximating N-1/2 by N-1). Consider now that you can decide on S, where you replace N=L/S (L is the length of the route). Find the value of S that minimises the travelling time of the passengers. d. In the same setting as (c), assume that some passengers do not go to the terminal but alight before. Explain if your answer from (c) would increase or decrease and why. If you need…arrow_forwardThe minimum cycle length for an intersection is determined to be 95 seconds. The critical lane group flow ratios were calculated as 0.235, 0.25, 0.17, and 0.125, respectively. Assuming 5 seconds lost per phase, determine which X was used.arrow_forward

- A four-phase traffic signal has critical lane group flow ratios of 0.250, 0.150, 0.225 and 0.125. If the lost time per phase is 4 seconds and a critical intersection v/c of 0.85 is desired, calculate the minimum cycle length and the phase effective green times such that the lane group v/c ratios are equalized.arrow_forwardA pre-timed four-phase signal has critical lane group flow rates for the first three phases of 260, 280, and 310 [veh/h] (saturation flow rates are 2000 [veh/h/ln] for all phases). The lost time is known to be 5 seconds for each phase. If the cycle length is 90 seconds, what is the estimated effective green time of the fourth phase?arrow_forwardPLEASE SOLVE THE QUESTIONS IN THE PICTURE, make sure you show all of your work please. Thank you for your help!arrow_forward

- Please solve the following question in the picture, make sure you show all of your work and formulas you use. Thank you so much for your help!arrow_forwardDetermine all the quantities mentioned. Show complete solution using Mohr's Circle only.arrow_forwardAnswer the following questions please.arrow_forward

Traffic and Highway EngineeringCivil EngineeringISBN:9781305156241Author:Garber, Nicholas J.Publisher:Cengage Learning

Traffic and Highway EngineeringCivil EngineeringISBN:9781305156241Author:Garber, Nicholas J.Publisher:Cengage Learning Construction Materials, Methods and Techniques (M...Civil EngineeringISBN:9781305086272Author:William P. Spence, Eva KultermannPublisher:Cengage Learning

Construction Materials, Methods and Techniques (M...Civil EngineeringISBN:9781305086272Author:William P. Spence, Eva KultermannPublisher:Cengage Learning Fundamentals Of Construction EstimatingCivil EngineeringISBN:9781337399395Author:Pratt, David J.Publisher:Cengage,

Fundamentals Of Construction EstimatingCivil EngineeringISBN:9781337399395Author:Pratt, David J.Publisher:Cengage, Principles of Geotechnical Engineering (MindTap C...Civil EngineeringISBN:9781305970939Author:Braja M. Das, Khaled SobhanPublisher:Cengage Learning

Principles of Geotechnical Engineering (MindTap C...Civil EngineeringISBN:9781305970939Author:Braja M. Das, Khaled SobhanPublisher:Cengage Learning Solid Waste EngineeringCivil EngineeringISBN:9781305635203Author:Worrell, William A.Publisher:Cengage Learning,

Solid Waste EngineeringCivil EngineeringISBN:9781305635203Author:Worrell, William A.Publisher:Cengage Learning,