Concept explainers

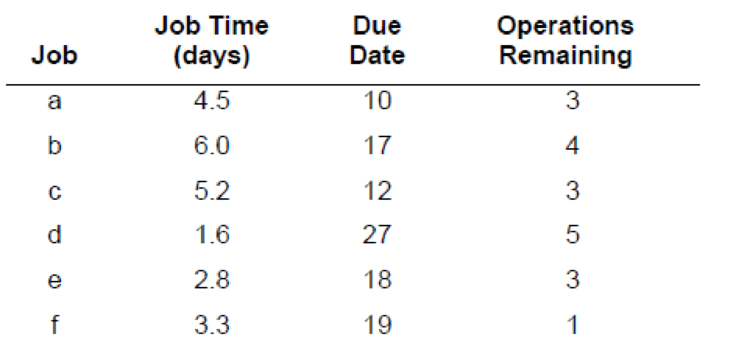

A foreman has determined processing times at a work center for a set of jobs and now wants to sequence them. Given the information shown, do the following:

a. Determine the processing sequence using (1) FCFS, (2) SPT, (3) EDD, and (4) CR. For each sequence, compute the average job tardiness, the average flow time, and the average number of jobs at the work center. The list is in FCFS order.

b. Using the results of your calculations in part a, show that the ratio of average flow time and the average number of jobs measures are equivalent for all four sequencing rules.

c. Determine the processing sequence that would result using the S/O rule.

a)

1)

To determine: The processing sequence based on First Come First Served (FCFS).

Introduction: First Come First Served is the scheduling rule, which helps to arrange the sequence in the order. Here, the first come would be served first.

Answer to Problem 15P

Explanation of Solution

Given information:

| Job | Processing time (days) | Due date (days) | Remaining number of operations |

| a | 4.5 | 10 | 3 |

| b | 6 | 17 | 4 |

| c | 5.2 | 12 | 3 |

| d | 1.6 | 27 | 5 |

| e | 2.8 | 18 | 3 |

| f | 3.3 | 19 | 1 |

Determine the sequence using FCFS:

According to FCFS, the first come would be served first. Hence, the jobs should be sequenced in the order as per its arrival.

Hence, the sequence of jobs using FCFS is a-b-c-d-e-f.

Determine average flow time, average tardiness, and average number of jobs for FCFS:

| Job | Processing time (days) | Flow time (days) | Due date (days) | Tardiness |

| a | 4.5 | 4.5 | 10 | 0 |

| b | 6 | 10.5 | 17 | 0 |

| c | 5.2 | 15.7 | 12 | 3.7 |

| d | 1.6 | 17.3 | 27 | 0 |

| e | 2.8 | 20.1 | 18 | 2.1 |

| f | 3.3 | 23.4 | 19 | 4.4 |

| Total | 23.4 | 91.5 | 10.2 |

Supporting calculation:

Processing time and due date are given for each job. Flow time is the cumulative of the processing time.

Tardiness of Job a:

Flowtime is less than the due date. Hence, there would be tardiness.

Tardiness of Job b:

Flowtime is less than the due date. Hence, there would be tardiness.

Tardiness of Job c:

It is calculated by subtracting the flow time of the job from the due date of the project. Hence, the lateness of Job c is 3.7.

Note: The procedure continues for all the jobs.

Average flow time:

It is calculated by dividing the total flow time and number of jobs.

Hence, average flow time is 15.25 days.

Average tardiness:

It is calculated by dividing the total tardiness and number of jobs.

Hence, average tardiness is 1.7 days.

Average number of jobs:

It can be determined by dividing the total flow time and total processing time.

Hence, average number of jobs is 3.9 jobs.

1)

To determine: The processing sequence based on First Come First Served (FCFS).

Introduction: First Come First Served is the scheduling rule, which helps to arrange the sequence in the order. Here, the first come would be served first.

Answer to Problem 15P

Explanation of Solution

Given information:

| Job | Processing time (days) | Due date (days) | Remaining number of operations |

| a | 4.5 | 10 | 3 |

| b | 6 | 17 | 4 |

| c | 5.2 | 12 | 3 |

| d | 1.6 | 27 | 5 |

| e | 2.8 | 18 | 3 |

| f | 3.3 | 19 | 1 |

Determine the sequence using FCFS:

According to FCFS, the first come would be served first. Hence, the jobs should be sequenced in the order as per its arrival.

Hence, the sequence of jobs using FCFS is a-b-c-d-e-f.

Determine average flow time, average tardiness, and average number of jobs for FCFS:

| Job | Processing time (days) | Flow time (days) | Due date (days) | Tardiness |

| a | 4.5 | 4.5 | 10 | 0 |

| b | 6 | 10.5 | 17 | 0 |

| c | 5.2 | 15.7 | 12 | 3.7 |

| d | 1.6 | 17.3 | 27 | 0 |

| e | 2.8 | 20.1 | 18 | 2.1 |

| f | 3.3 | 23.4 | 19 | 4.4 |

| Total | 23.4 | 91.5 | 10.2 |

Supporting calculation:

Processing time and due date are given for each job. Flow time is the cumulative of the processing time.

Tardiness of Job a:

Flowtime is less than the due date. Hence, there would be tardiness.

Tardiness of Job b:

Flowtime is less than the due date. Hence, there would be tardiness.

Tardiness of Job c:

It is calculated by subtracting the flow time of the job from the due date of the project. Hence, the lateness of Job c is 3.7.

Note: The procedure continues for all the jobs.

Average flow time:

It is calculated by dividing the total flow time and number of jobs.

Hence, average flow time is 15.25 days.

Average tardiness:

It is calculated by dividing the total tardiness and number of jobs.

Hence, average tardiness is 1.7 days.

Average number of jobs:

It can be determined by dividing the total flow time and total processing time.

Hence, average number of jobs is 3.9 jobs.

2)

To determine: Sequence of jobs based on decision rule Shortest Processing Time (SPT).

Introduction: Shortest Processing Tine is the scheduling rule, which helps to arrange the sequence in the order. Here, job with the shortest duration would be served first. Then, the process would be going on from shortest to largest duration.

Answer to Problem 15P

Explanation of Solution

Given information:

| Job | Processing time (days) | Due date (days) | Remaining number of operations |

| a | 4.5 | 10 | 3 |

| b | 6 | 17 | 4 |

| c | 5.2 | 12 | 3 |

| d | 1.6 | 27 | 5 |

| e | 2.8 | 18 | 3 |

| f | 3.3 | 19 | 1 |

Determine the sequence using SPT:

According to SPT, the job that has the shortest processing would be served first and it goes on as the processing time increase. Duration should be assembled in the ascending order

Hence, the sequence of jobs using SPT is d-e-f-a-c-b.

Determine average flow time, average tardiness, and average number of jobs for SPT:

| Job | Processing time (days) | Flow time (days) | Due date (days) | Tardiness |

| d | 1.6 | 1.6 | 27 | |

| e | 2.8 | 4.4 | 18 | |

| f | 3.3 | 7.7 | 19 | |

| a | 4.5 | 12.2 | 10 | 2.2 |

| c | 5.2 | 17.4 | 12 | 5.4 |

| b | 6 | 23.4 | 17 | 6.4 |

| Total | 23.4 | 66.7 | 14 |

Supporting calculation:

Processing time and due date are given for each job. Flow time is the cumulative of the processing time.

Tardiness of Job d, Job e, and Job f:

Flow time of Job d, Job e, and Job f is less than its respective due date. Hence, there would be no tardiness.

Tardiness of Job a:

It is calculated by subtracting the flow time of the job from the due date of the project. Hence, the lateness of Job a is 2.2.

Tardiness of Job c:

It is calculated by subtracting the flow time of the job from the due date of the project. Hence, the lateness of Job c is 5.4.

Tardiness of Job b:

It is calculated by subtracting the flow time of the job from the due date of the project. Hence, the lateness of Job b is 6.4.

Average flow time:

It is calculated by dividing the total flow time and number of jobs.

Hence, average flow time is 11.12 days.

Average tardiness:

It is calculated by dividing the total tardiness and number of jobs.

Hence, average tardiness is 2.33 days.

Average number of jobs:

It can be determined by dividing the total flow time and total processing time.

Hence, average number of jobs is 2.85 jobs.

3)

To determine: Sequence of jobs based on decision rule Earliest Due Date (EDD).

Introduction: Earliest Due Date is the scheduling rule, which helps to arrange the sequence in the order. Here, job with the earliest due date would be served first. Then, the process would be going on from earliest due date to latest due date.

Answer to Problem 15P

Explanation of Solution

Given information:

| Job | Processing time (days) | Due date (days) | Remaining number of operations |

| a | 4.5 | 10 | 3 |

| b | 6 | 17 | 4 |

| c | 5.2 | 12 | 3 |

| d | 1.6 | 27 | 5 |

| e | 2.8 | 18 | 3 |

| f | 3.3 | 19 | 1 |

Determine the sequence using EDD:

According to EDD, the job that has the earliest due date would be served first and it goes on as the due date increases. The job should be arranged based on due date. Due date should be assembled in the ascending order

Hence, the sequence of jobs using EDD is a-c-b-e-f-d.

Determine average flow time, average tardiness, and average number of jobs for EDD:

| Job | Processing time (days) | Flow time (days) | Due date (days) | Tardiness |

| a | 4.5 | 4.5 | 10 | 0 |

| c | 5.2 | 9.7 | 12 | 0 |

| b | 6 | 15.7 | 17 | 0 |

| e | 2.8 | 18.5 | 18 | 0.5 |

| f | 3.3 | 21.8 | 19 | 2.8 |

| d | 1.6 | 23.4 | 27 | 0 |

| Total | 23.4 | 93.6 | 3.3 |

Supporting calculation:

Processing time and due date are given for each job. Flow time is the cumulative of the processing time.

Tardiness of Job a, Job c, Job b, and Job d:

Flow time of Job a, Job c, Job b, and Job d is less than its respective due date. Hence, there would be no tardiness.

Tardiness of Job e:

It is calculated by subtracting the flow time of the job from the due date of the project. Hence, the lateness of Job e is 0.5.

Tardiness of Job f:

It is calculated by subtracting the flow time of the job from the due date of the project. Hence, the lateness of Job f is 2.8.

Average flow time:

It is calculated by dividing the total flow time and number of jobs.

Hence, average flow time is 15.6 days.

Average tardiness:

It is calculated by dividing the total tardiness and number of jobs.

Hence, average tardiness is 0.55 days.

Average number of jobs:

It can be determined by dividing the total flow time and total processing time.

Hence, average number of jobs is 4 jobs.

4)

To determine: Sequence of jobs based on decision rule critical ratio.

Introduction: Critical ratio is kind of scheduling rule that helps to identify that, the task or job is on the correct track. It would help to identify if the task is behind or ahead of the schedule.

Answer to Problem 15P

Explanation of Solution

Given information:

| Job | Processing time (days) | Due date (days) | Remaining number of operations |

| a | 4.5 | 10 | 3 |

| b | 6 | 17 | 4 |

| c | 5.2 | 12 | 3 |

| d | 1.6 | 27 | 5 |

| e | 2.8 | 18 | 3 |

| f | 3.3 | 19 | 1 |

Determine the sequence using critical ratio:

Initial critical ratio should be determined at day 0:

| Job | Processing time (days) | Due date (days) | Critical ratio |

| a | 4.5 | 10 | 2.22 |

| b | 6 | 17 | 2.83 |

| c | 5.2 | 12 | 2.31 |

| d | 1.6 | 27 | 16.88 |

| e | 2.8 | 18 | 6.43 |

| f | 3.3 | 19 | 5.76 |

Critical ratio for Job a:

It is can be determined by dividing the value attained by subtracting the completion day of previous job from the due date of current job with the processing time.

Note: Process continues for all the jobs.

Job a has the lowest critical ratio. Thus, it will be completed first. Hence, Job a would be completed first in the sequence of jobs.

Determine the critical ratio after the completion of Job a:

As the processing time of job a is 4.5 days, completion day of completed day would be 4.5.

| Job | Processing time (days) | Due date (days) | Critical ratio |

| a | |||

| b | 6 | 17 | 2.08 |

| c | 5.2 | 12 | 1.44 |

| d | 1.6 | 27 | 14.06 |

| e | 2.8 | 18 | 4.82 |

| f | 3.3 | 19 | 4.39 |

Critical ratio for Job b:

It is can be determined by dividing the value attained by subtracting the completion day of completed job from the due date of current job with the processing time.

Note: Process continues for all the jobs.

Job c has the lowest critical ratio. Hence, Job c would be completed next in the sequence of jobs.

Determine the critical ratio after the completion of Job a and Job c:

As the processing time of job a is 4.5 days and Job c is 5.2, completion day of completed day would be 9.7 (4.5+5.2).

| Job | Processing time (days) | Due date (days) | Ratio |

| a | |||

| b | 6 | 17 | 1.22 |

| c | |||

| d | 1.6 | 27 | 10.81 |

| e | 2.8 | 18 | 2.96 |

| f | 3.3 | 19 | 2.82 |

Critical ratio for Job b:

It is can be determined by dividing the value attained by subtracting the completion day of completed job from the due date of current job with the processing time.

Job b has the lowest critical ratio. Hence, Job b would be completed next in the sequence of jobs after Job a and Job c.

Determine the critical ratio after the completion of Job a, Job c and Job b:

As the processing time of job a is 4.5 days, Job b is 6.0, and Job c is 5.2 days. Completion day of completed day would be 15.7 (4.5+5.2+6).

| Job | Processing time (days) | Due date (days) | Ratio |

| a | |||

| b | |||

| c | |||

| d | 1.6 | 27 | 7.06 |

| e | 2.8 | 18 | 0.82 |

| f | 3.3 | 19 | 1 |

Critical ratio for Job d:

It is can be determined by dividing the value attained by subtracting the completion day of completed job from the due date of current job with the processing time.

Job e has the lowest critical ratio. Hence, Job e would be completed next in the sequence of jobs after Job a, Job c, and Job b.

Determine the critical ratio after the completion of Job a, Job c, Job b, and job e:

As the processing time of job a is 4.5 days, Job b is 6.0, Job c is 5.2 days, and job e is 2.8. Completion day of completed day would be 18.5 (4.5+5.2+6+2.8).

| Job | Processing time (days) | Due date (days) | Ratio |

| a | |||

| b | |||

| c | |||

| d | 1.6 | 27 | 5.31 |

| e | |||

| f | 3.3 | 19 | 0.15 |

Critical ratio for Job d:

It is can be determined by dividing the value attained by subtracting the completion day of completed job from the due date of current job with the processing time.

Job f has the lowest critical ratio. Hence, Job f would be completed next in the sequence of jobs after Job a, Job c, Job b, and Job e.

As Job d is the remaining job, it will be completed next.

Hence, the sequence of jobs using critical ratio is a-c-b-e-f-d.

Determine average flow time, average tardiness, and average number of jobs for critical ratio:

| Job | Processing time (days) | Flow time (days) | Due date (days) | Tardiness |

| a | 4.5 | 4.5 | 10 | 0 |

| c | 5.2 | 9.7 | 12 | 0 |

| b | 6 | 15.7 | 17 | 0 |

| e | 2.8 | 18.5 | 18 | 0.5 |

| f | 3.3 | 21.8 | 19 | 2.8 |

| d | 1.6 | 23.4 | 27 | 0 |

| Total | 23.4 | 93.6 | 3.3 |

Supporting calculation:

Processing time and due date are given for each job. Flow time is the cumulative of the processing time.

Tardiness of Job a, Job c, Job b, and Job d:

Flow time of Job a, Job c, Job b, and Job d is less than its respective due date. Hence, there would be no tardiness.

Tardiness of Job e:

It is calculated by subtracting the flow time of the job from the due date of the project. Hence, the lateness of Job e is 0.5.

Tardiness of Job f:

It is calculated by subtracting the flow time of the job from the due date of the project. Hence, the lateness of Job f is 2.8.

Average flow time:

It is calculated by dividing the total flow time and number of jobs.

Hence, average flow time is 15.6 days.

Average tardiness:

It is calculated by dividing the total tardiness and number of jobs.

Hence, average tardiness is 0.55 days.

Average number of jobs:

It can be determined by dividing the total flow time and total processing time.

Hence, average number of jobs is 4 jobs.

b)

To determine: Whether the average flow time and average number of jobs are equivalent for four sequencing rules.

Introduction: Sequencing is the process of arranging the jobs in certain order in which it should be performed.

Answer to Problem 15P

Explanation of Solution

Given information:

| Job | Processing time (days) | Due date (days) | Remaining number of operations |

| a | 4.5 | 10 | 3 |

| b | 6 | 17 | 4 |

| c | 5.2 | 12 | 3 |

| d | 1.6 | 27 | 5 |

| e | 2.8 | 18 | 3 |

| f | 3.3 | 19 | 1 |

Determine whether the average flow time and average number of jobs are equivalent for four sequencing rules:

| Rule | Average flow time | Average number of jobs | Ratio |

| FCFS | 15.25 | 3.91 | 3.9 |

| SPT | 11.12 | 2.85 | 3.9 |

| EDD | 15.6 | 4 | 3.9 |

| CR | 15.6 | 4 | 3.9 |

Calculate ratio for FCFS:

It is calculated by dividing average flow time and average number of jobs.

Calculate ratio for SPT:

It is calculated by dividing average flow time and average number of jobs.

Calculate ratio for EDD:

It is calculated by dividing average flow time and average number of jobs.

Calculate ratio for CR:

It is calculated by dividing average flow time and average number of jobs.

c)

To determine: The processing sequence of the jobs using Slack per Operation (S/O) rule

Introduction: Slack per operation is a scheduling method that helps to determine the sequence of the operation. Slack is the difference between the due date and the required time to process certain job.

Answer to Problem 15P

Explanation of Solution

Given information:

The following information is given:

| Job | Processing time (days) | Due date | Remaining number of operations |

| a | 5 | 8 | 2 |

| b | 6 | 5 | 4 |

| c | 9 | 10 | 4 |

| d | 7 | 12 | 3 |

| e | 8 | 10 | 2 |

Determine the processing sequence of the jobs using Slack per Operation:

| Job | Job time (days) | Due date (days) | Operations remaining | Slack | Slack per operation (S/O) | Rank |

| a | 4.5 | 10 | 3 | 5.5 | 1.83 | 1 |

| b | 6 | 17 | 4 | 11 | 2.75 | 3 |

| c | 5.2 | 12 | 3 | 6.8 | 2.27 | 2 |

| d | 1.6 | 27 | 5 | 25.4 | 5.08 | 5 |

| e | 2.8 | 18 | 3 | 15.2 | 5.07 | 4 |

| f | 3.3 | 19 | 1 | 15.7 | 15.7 | 6 |

Supporting calculation:

Processing time, due date, and remaining number of operation is given. Rank should be assigned according to the slack per operation.

Calculate slack:

It can be calculated by subtracting the processing time from the due date.

Note: The process continues for all the jobs:

Calculate slack per operation:

It can be calculated by dividing the slack value and the remaining number of operations.

Note: The process continues for all the jobs:

Hence, the sequence of jobs using S/O is a-c-b-e-d-f.

Want to see more full solutions like this?

Chapter 16 Solutions

EBK OPERATIONS MANAGEMENT

- ASSIGNMENT: Production Sheet Watch at least 3 workers prepare foods. Write down what they do and the amount of time it takes for them to complete the task. Calculate the production cost. Example: Food Item: Green Beans Time Worker #1 Worker #2 Worker #3 Start End Time (Hours) Time Time Activity Activity Activity (Hours) (Hours) 11:45 am 12:01 pm 0.27 Steam and 0.05 Microwave blenderize pureed frozen green green beans beans 16.25 Total Production Time 3 minutes minutes Hourly Wage $16.07 $12.28 24% Benefits *** $3.86 $2.95 Labor Costs $5.37 $0.76 *** Check with facility to see Benefit %arrow_forwardMenu Planning and Quality Monitoring Rotation site: Hospital/Commercial Foodservice Rotation Objectives: Menu development (this will be your Theme Meal) 1. Develop a modified menu (vegetarian, vegan, gluten-free, etc.) that is appropriate in texture, color, flavor, eye appeal, temperature, and methods of preparation. 2. Develop a menu that takes into consideration food preferences due to clients' ethnicity and age group. 3. Develop menus that fulfill the nutritional needs of the target population. 4. Develop a modified menu that maintains consistency with a regular menu. 5. Demonstrate knowledge of operational constraints and limitations when designing menus 6. Identify appropriate type and amounts of foods for an emergency plan. ACTIVITY: Quality improvement monitoring 1. Participates in rounds to get feedback from clients on Theme Meal menu. 2. Takes corrective actions if necessary according to results of the quality measures 3. Completes one or more critical incident reports for the…arrow_forwardWork with the chef and/or production manager to identify a menu item (or potential menu item) for which a standardized recipe is needed. Record the recipe with which you started and expand it to meet the number of servings required by the facility. Develop an evaluation rubric. Conduct an evaluation of the product. There should be three or more people evaluating the product for quality. Write a brief report of this activity • Product chosen and the reason why it was selected When and where the facility could use the product The standardized recipe sheet or card ○ Use the facility's format or о Design one of your own using a form of your choice; be sure to include the required elements Recipe title " Yield and portion size ■ Cooking time and temperature Ingredients and quantities Specify AP or EP Procedures (direction)arrow_forward

- Item Prepared: Work with one or more cold food production workers to learn job descriptions, flow of work, how the menu items are prepared and served, and needs for further training or process improvement. Document a specific menu item you prepared. Record the temperature of a product when it goes into the refrigerator or blast chiller. Record how long it took for the product to cool to the appropriate temperature. Evaluate the menu item you were involved in preparing. Follow the product and process to completion and utilize resources to correct any wrong procedures you observe. Take your notes and write a brief report of the actual experience based on the following criteria: 1. Pre-preparation 2. Preparation 3. Compare menu item to diets it is used for by completing a nutritional analysis 4. Temperatures during and after preparation. 5. Tray service to patient or guest (how it looks, holds up, appropriate temperature maintained from production through delivery) 6. Waste disposal (what…arrow_forwardWork with one or more hot food production workers to learn job descriptions, flow of work, how the menu items are prepared and served, and needs for further training or process improvement. Document a specific menu item you prepared. Record the temperature of a product when it is done. If it is to be chilled and reheated later, systematically measure the temperature every 30 minutes and record how long it takes the product to reach a safe temperature for storage. Evaluate the menu item you were involved in preparing. Follow the product and process to completion and utilize resources to correct any wrong procedures you observe. Take notes and write a brief report of the actual experience based on the following criteria: 1. Pre-preparation 2. Preparation 3. Compare menu item to diets it is used for by completing a nutritional analysis 4. Temperatures during and after preparation. 5. Tray service to patient or guest (how it looks, holds up, appropriate temperature maintained from…arrow_forwardRefrigerated/Freezer- Dietary Mangement (Nursing Home) Describe the refrigerated/freezer storage area and procedures. Are any of the refrigerated/ frozen areas locked? Who has access? What kind of shelving is used? Are there any products stored on the floor? Are the items dated as received? How is the stock rotated to ensure that the oldest items are used first? Are temperature and humidity monitored? If yes, how? Has mold ever been a problem? Are there any regular procedures in place to control it? How often are the refrigerated/freezer storage areas cleaned?arrow_forward

- RECEIVING AND STORAGE ASSIGNMENTS- Dietary Mangement (Nursing Home) ASSIGNMENT: Diagram the receiving and storage areas. Use arrows to show the flow of goods as they are received and moved to storage. ASSIGNMENT: In order to accurately understand this area, the intern should work in the receiving area to complete the following assignments and answer the following questions: Inspect the delivery and check it against the purchase Inspect the delivery against the invoice Accept order only if all quantities and quality specifications are met Check perishable items first Check temperatures of refrigerated and frozen items on arrival Look for evidence of thawing or freezer burn Randomly open cases to check contents Complete receiving records Transfer goods to appropriate storage Who checks the packing slip against the invoice? Does the facility ever use “blind” receiving where the receiving clerk checks the order against an invoice where the amounts have been blanked out and the clerk…arrow_forwardPurchasing, Receiving, Storage, and Inventory Instructions- Dietary management in a nursing home in ABQ NM What workers are involved in the purchasing, receiving, storage and inventory process. Complete the table below: Position Description of their job duties Date/ What did they do? Answer the questions below: PURCHASING: 1. Is there a centralized purchasing department for the facility? If yes, observe someone in that department for a half day if possible, if no write N/A 2. What kinds of items are required to go out for formal bid? 3. What about capital purchases? What is the dollar amount at which an item must go on the capital rather than the operating budget? 4. Does the facility participate with a group to cooperatively purchase items? 5. Is there a Prime Vendor? If yes, how often is the contract renegotiated? 6. Is informal or open-market buying used for any items? Which ones? 7. Who orders…arrow_forwardCritical Incident Report- Dietary Mangement Critical incidences involve critical thinking and problem solving techniques. This exercise is the opportunity to analyze and decide on the appropriateness of the action and to determine better ways to solve problems, approach employees and get the job done. This exercise should help in doing it better the next time. As you observe or become more involved in the situations that require problem solving or critical thinking use this exercise to identify the what, who, and when and determine how the actions taken or not taken affected the outcome. You must write up two or more experiences. The summary is to include two parts: 1. Objective data of what occurred and how it occurred: 2. Analysis of what happened and what we could or would have done to make the outcome better.arrow_forward

- Prepare a graph of the monthly forecasts and average forecast demand for Chicago Paint Corp., a manufacturer of specialized paint for artists. Compute the demand per day for each month (round your responses to one decimal place). Month B Production Days Demand Forecast Demand per Day January 21 950 February 19 1,150 March 21 1,150 April 20 1,250 May 23 1,200 June 22 1,000' July 20 1,350 August 21 1,250 September 21 1,050 October 21 1,050 November 21 December 225 950 19 850arrow_forwardThe president of Hill Enterprises, Terri Hill, projects the firm's aggregate demand requirements over the next 8 months as follows: 2,300 January 1,500 May February 1,700 June 2,100 March April 1,700 1,700 July August 1,900 1,500 Her operations manager is considering a new plan, which begins in January with 200 units of inventory on hand. Stockout cost of lost sales is $125 per unit. Inventory holding cost is $25 per unit per month. Ignore any idle-time costs. The plan is called plan C. Plan C: Keep a stable workforce by maintaining a constant production rate equal to the average gross requirements excluding initial inventory and allow varying inventory levels. Conduct your analysis for January through August. The average monthly demand requirement = units. (Enter your response as a whole number.) In order to arrive at the costs, first compute the ending inventory and stockout units for each month by filling in the table below (enter your responses as whole numbers). Ending E Period…arrow_forwardMention four early warning indicators that a business may be at risk.arrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Understanding Management (MindTap Course List)ManagementISBN:9781305502215Author:Richard L. Daft, Dorothy MarcicPublisher:Cengage Learning

Understanding Management (MindTap Course List)ManagementISBN:9781305502215Author:Richard L. Daft, Dorothy MarcicPublisher:Cengage Learning