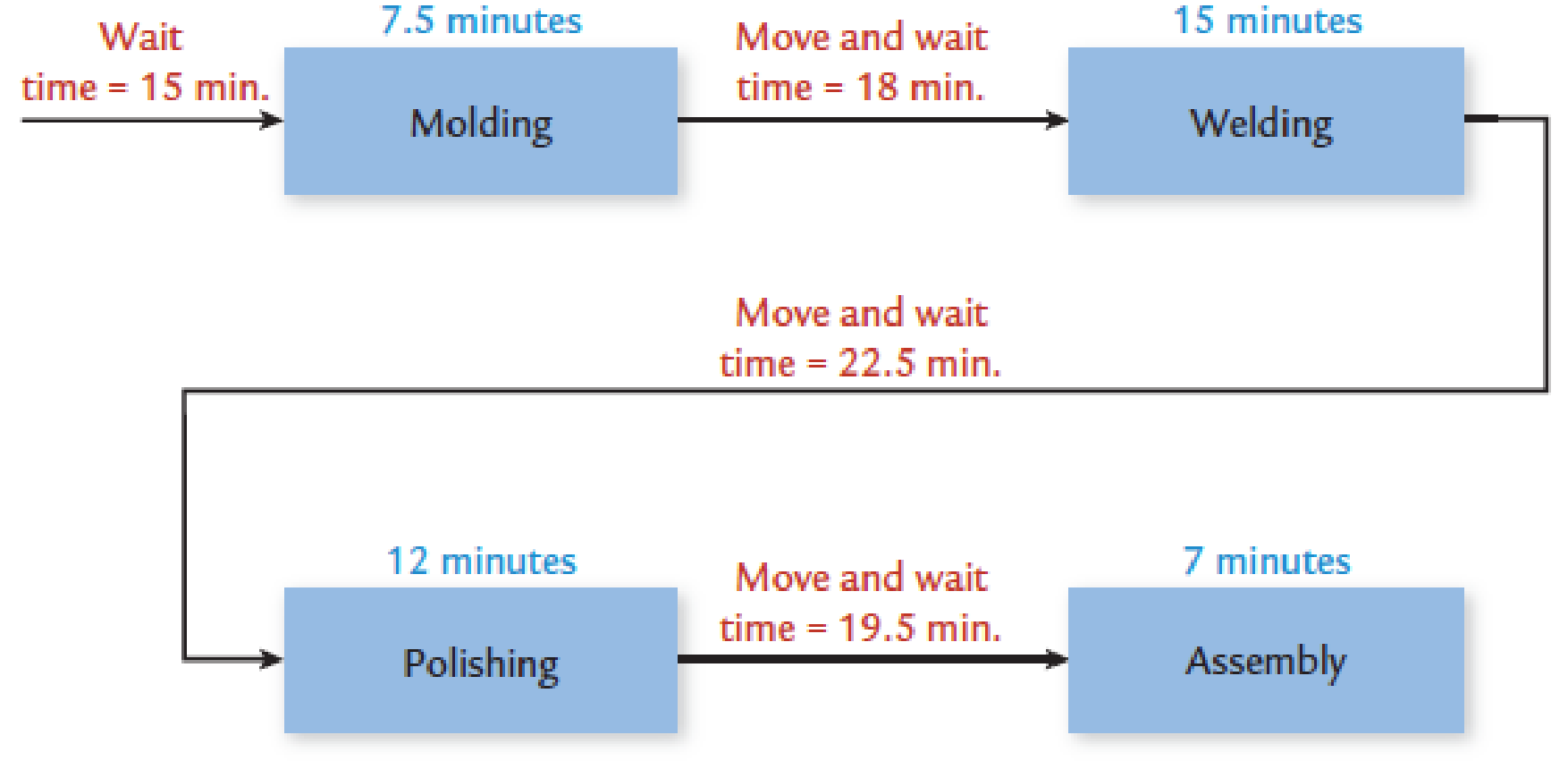

Anderson Company has the following departmental manufacturing structure for one of its products:

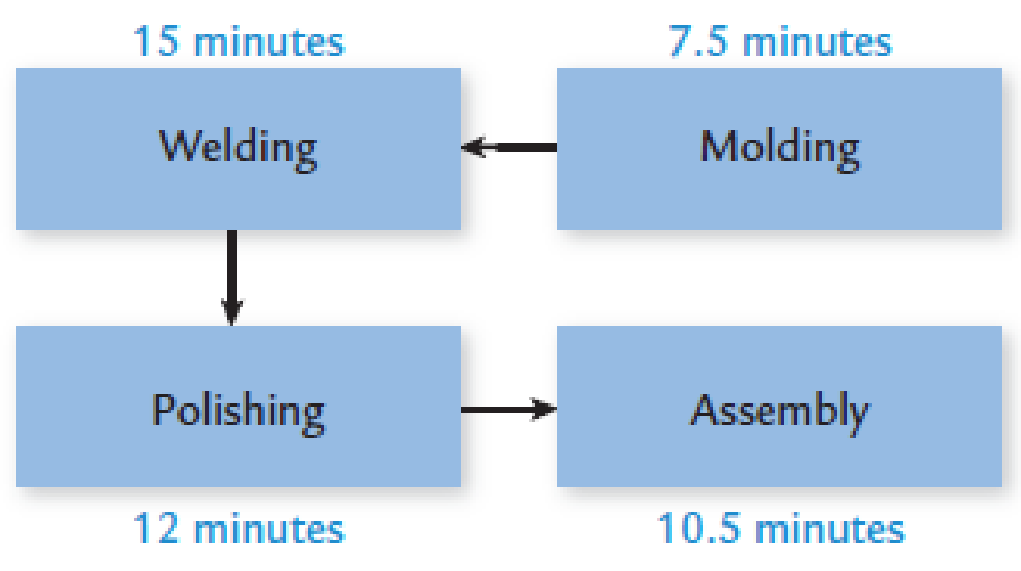

After some study, the production manager of Anderson recommended the following revised cellular manufacturing approach:

Required:

- 1. Calculate the total time it takes to produce a batch of 20 units using Anderson’s traditional departmental structure.

- 2. Using cellular manufacturing, how much time is saved producing the same batch of 20 units? Assuming the cell operates continuously, what is the production rate? Which process controls this production rate?

- 3. What if the processing times of molding, welding, and assembly are all reduced to six minutes each? What is the production rate now, and how long will it take to produce a batch of 20 units?

1.

Compute the total time taken for the production of a batch of 20 units using the traditional departmental structure.

Explanation of Solution

Traditional departmental structure: The traditional departmental structure refers to the conventional manufacturing approach, wherein the manufacturing is a process which includes lots of lead time.

Compute the total time taken for the production of a batch of 20 units using the traditional departmental structure.

| Batch Time: | |

| Processing time: | |

| Molding (1) | 150 mins |

| Welding (2) | 300 mins |

| Polishing (3) | 240 mins |

| Assembly (4) | 140 mins |

| Total Processing Time | 830 mins |

| Move and wait time (5) | 75 mins |

| Total Batch Time | 905 mins |

Table (1)

Working Notes (1):

Calculate the processing time for Molding:

Working Notes (2):

Calculate the processing time for Welding:

Working Notes (3):

Calculate the processing time for Polishing:

Working Notes (4):

Calculate the processing time for Assembly:

Working Notes (5):

Calculate the Move and wait time:

2.

Compute the total time taken for the production of a batch of 20 units using the cellular manufacturing approach and the production rate if it’s a continuous production and identify the process which controls the production rate.

Explanation of Solution

Cellular manufacturing: The cellular manufacturing refers to the manufacturing approach, wherein the various equipments related to the various processes of production are clustered together to avoid any move time and enable faster manufacturing of the goods.

Compute the total time taken for the production of a batch of 20 units using the cellular manufacturing.

| Batch Time: | |

| Processing time: | |

| For First Unit | 45 mins |

| Second unit | 60 mins |

| Third Unit | 75 mins |

| Fourth unit | 90 mins |

| Fifth Unit | 105 mins |

| Sixth unit | 120 mins |

| Seventh Unit | 135 mins |

| Eighth unit | 150 mins |

| Ninth Unit | 165 mins |

| Tenth unit | 180 mins |

| Eleventh Unit | 195 mins |

| Twelfth unit | 210 mins |

| Thirteenth Unit | 225 mins |

| Fourteenth Unit | 240 mins |

| Fifteenth Unit | 255 mins |

| Sixteenth Unit | 270 mins |

| Seventeenth Unit | 285 mins |

| Eighteenth Unit | 300 mins |

| Nineteenth Unit | 315 mins |

| Twentieth Unit | 330 mins |

| Total Processing Time | 330 mins |

Table (2)

The total processing time of 1 unit is 45 minutes (refer Working Notes (6)). The production of the second unit starts once in every fifteen minutes, so that the production process can go on without stopping in middle. Thus 15 mins is added to the processing time of previous every unit, to get the processing time of the present unit.

The production time for a batch of 20 units using cellular manufacturing is 330 mins. The production of 20 units under the traditional departmental structure has a production time is 905 mins. Hence, the total production time saved using the cellular manufacturing approach is 605 mins

The production rate uses the processing time of the process with the longest processing time, thus the Welding process with 15 mins processing time is used.

The new Production rate is 4 units per hour

The production of every unit starts once in fifteen minutes and for 20 units the production time is 300 mins

The production starts once in every fifteen minutes, as Welding process takes 15 mins to be completed and is the bottleneck process in the production, as it controls the production rate.

Working Notes (6):

Calculate the total Processing time:

3.

Identify the new processing time and the production rate if the processing time for welding, molding and assembly are reduced by 6 minutes each.

Explanation of Solution

The production rate uses the processing time of the process with the longest processing time, thus the Polishing process with 12 mins processing time is used.

The new Production rate is 5 units per hour

The production of every unit starts once in twelve minutes and for 20 units the production time is 240 mins

Compute the new total processing time for the production of a batch of 20.

| Batch Time: | |

| Processing time: | |

| For First Unit | 27 mins |

| Second unit | 39 mins |

| Third Unit | 51 mins |

| Fourth unit | 63 mins |

| Fifth Unit | 75 mins |

| Sixth unit | 87 mins |

| Seventh Unit | 99 mins |

| Eighth unit | 111 mins |

| Ninth Unit | 123 mins |

| Tenth unit | 135 mins |

| Eleventh Unit | 147 mins |

| Twelfth unit | 159 mins |

| Thirteenth Unit | 171 mins |

| Fourteenth Unit | 183 mins |

| Fifteenth Unit | 195 mins |

| Sixteenth Unit | 207 mins |

| Seventeenth Unit | 219 mins |

| Eighteenth Unit | 231 mins |

| Nineteenth Unit | 243 mins |

| Twentieth Unit | 255 mins |

| Total Processing Time | 255 mins |

Table (3)

The total processing time of 1 unit is 27 minutes (refer Working Notes (7)). The production of the second unit starts once in every twelfth minutes, so that the production process can go on without stopping in middle. Thus 12 mins is added to the processing time of previous every unit, to get the processing time of the present unit.

The production time for a batch of 20 units using cellular manufacturing is 255 mins.

Working Notes (7):

Calculate the total Processing time:

Want to see more full solutions like this?

Chapter 15 Solutions

Cornerstones of Cost Management (Cornerstones Series)

- Suppose Chrysler Motors has 720 million shares outstanding with a share price of $68.25, and $30 billion in debt. If in three years, Chrysler has 750 million shares outstanding trading for $76 per share, how much debt will Chrysler have if it maintains a constant debt-equity ratio? Correct Answerarrow_forwardHow much is Henry Enterprises break even point?arrow_forwardSuppose Chrysler Motors has 720 million shares outstanding with a share price of $68.25, and $30 billion in debt. If in three years, Chrysler has 750 million shares outstanding trading for $76 per share, how much debt will Chrysler have if it maintains a constant debt-equity ratio? Accounting Answerarrow_forward

- Need help with this question solution general accountingarrow_forwardNo WRONG ANSWERarrow_forwardSuppose Chrysler Motors has 720 million shares outstanding with a share price of $68.25, and $30 billion in debt. If in three years, Chrysler has 750 million shares outstanding trading for $76 per share, how much debt will Chrysler have if it maintains a constant debt-equity ratio? Answer this Questionarrow_forward

- Based on this informationarrow_forwardHi expert please give me answer general accounting questionarrow_forwardSuppose Chrysler Motors has 720 million shares outstanding with a share price of $68.25, and $30 billion in debt. If in three years, Chrysler has 750 million shares outstanding trading for $76 per share, how much debt will Chrysler have if it maintains a constant debt-equity ratio?arrow_forward

Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage Learning

Cornerstones of Cost Management (Cornerstones Ser...AccountingISBN:9781305970663Author:Don R. Hansen, Maryanne M. MowenPublisher:Cengage Learning Essentials of Business Analytics (MindTap Course ...StatisticsISBN:9781305627734Author:Jeffrey D. Camm, James J. Cochran, Michael J. Fry, Jeffrey W. Ohlmann, David R. AndersonPublisher:Cengage Learning

Essentials of Business Analytics (MindTap Course ...StatisticsISBN:9781305627734Author:Jeffrey D. Camm, James J. Cochran, Michael J. Fry, Jeffrey W. Ohlmann, David R. AndersonPublisher:Cengage Learning