Concept explainers

Determine material requirements plans for pans N and V and subassembly I as described in Solved Problem 3 for each of the following:

a. Assume that there are currently 100 Ns on hand and scheduled receipts of 40 Is and 10 Vs at the beginning of week 3. No Es are on hand: 120 Es are needed at the start of week 5.

b. Assume on-hand and scheduled receipts as in part a. Now suppose that 100 Es are needed at the stmt of week 5 and 55 at the start of week 7. Also, use multiples of these order sizes: N, 800; V, 200. Use lot-for-lot ordering for I.

C. Using your answer to part b, update the MRP for V, using the following additional information for each of these cases: (1) one week has elapsed (making it the start of week 2), and (2) three weeks have elapsed (making it the start of week 4).

The updated master

a)

To prepare A Material requirement plan for the given information.

Introduction: Materials Requirement Planning (MRP) is the planning or scheduling system, which is used in the manufacturing process. It is used to plan the number of items required to produce one unit of finished goods (end item).

Explanation of Solution

Given information:

On-hand balances are 100 units of Component N and 0 units of Component E. Scheduled receipts is 40 units of Component I and 10 units of Component C would arrive at the beginning of Week 3. 120 units of Component E are needed at the beginning of Week 5.

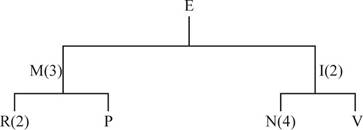

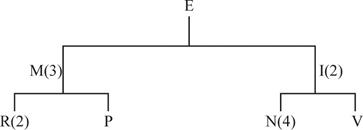

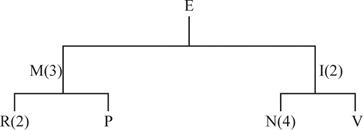

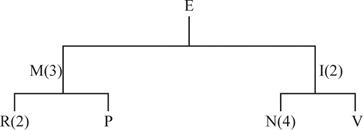

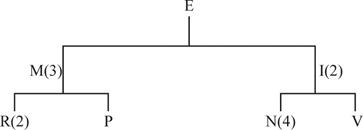

Product structure tree:

Prepare master schedule:

| Week | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| Quantity | 120 |

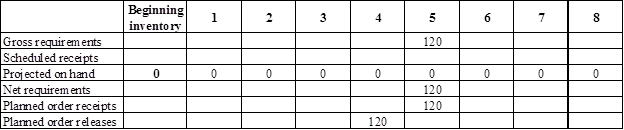

Develop a material requirement planning for End item E:

- It is given that Person X has received an order to deliver 120 units of End item E, which must be shipped at the start of week 5.

- Beginning inventory is given as 0 units.

- Net requirement can be calculated by subtracting the projected on-hand from the gross requirement. Hence, the net requirement is 120 units (120-0).

- Planned order release is the order given by the company and planned order receipts is the order received by the firm.

- Lead-time is given as 1 week. Company requires 120 units in the beginning of week 5. Hence, they need to order for 120 units (as the lot size is lot-for-lot) on previous week (as the lead-time is 1 week). Thus, company need to order the required units in week 4.

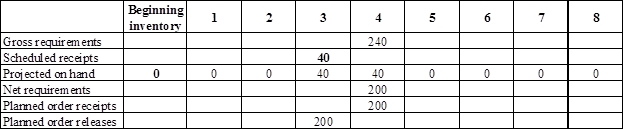

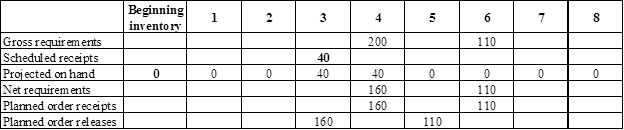

Develop a material requirement planning for Component I (2):

- End item E is the parent item of Component I (2). Hence, the planned order release of E is the gross requirement for Component I (2). As number of units required is 2 for Component I, the planned order release row should be multiplied with 2 to attain the gross requirement column of Component I.

- Beginning inventory is given as 0 units.

- Scheduled receipt is 40 units at the beginning of week 3.

- Net requirement can be calculated by subtracting the projected on-hand from the gross requirement. Hence, the net requirement is 200 units on week 4 (240-40).

- Planned order release is the order given by the company and planned order receipts is the order received by the firm.

- Lead-time is given as 1 week. Company requires 200 units in the beginning of week 4. Hence, they need to order for 200 units (as the lot size is lot-for-lot) on previous week (as the lead-time is 1 week). Thus, company need to order the required units in week 3.

- Projected on hand inventory for week 5 is 0 units. Calculation is as follows:

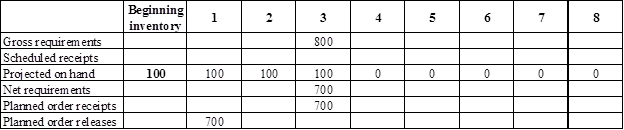

Develop a material requirement planning for Component N (4):

- Component I (2) is the parent item of Component N (4). Hence, the planned order release of Component I (2) is the gross requirement for Component N (4). As number of units required is 4 for Component N, the planned order release row should be multiplied with 2 to attain the gross requirement column of Component N.

- Beginning inventory is given as 100 units.

- Net requirement can be calculated by subtracting the projected on-hand from the gross requirement. Hence, the net requirement is 700 units on week 3 (800-100).

- Planned order release is the order given by the company and planned order receipts is the order received by the firm.

- Lead-time is given as 2 weeks. The company requires 700 units in the beginning of week 3. Hence, they need to order for 700 units (as the lot size is lot-for-lot) two weeks before (as the lead-time is 2 weeks). Thus, company need to order the required units in week 1.

- Projected on hand inventory for week 4 is 0 units. Calculation is as follows:

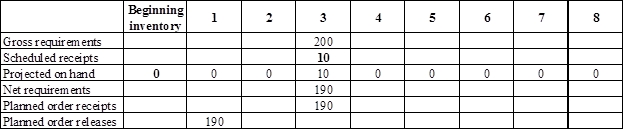

Develop a material requirement planning for Component V:

- Component I (2) is the parent item of Component V. Hence, the planned order release of Component I (2) is the gross requirement for Component V. As number of units required is 1 for Component V, the planned order release row should be multiplied with 1 to attain the gross requirement column of Component V.

- Beginning inventory is given as 0 units.

- Scheduled receipt is 10 units at the beginning of week 3.

- Net requirement can be calculated by subtracting the projected on-hand from the gross requirement. Hence, the net requirement is 190 units on week 3 (200-10).

- Planned order release is the order given by the company and planned order receipts is the order received by the firm.

- Lead-time is given as 2 weeks. The company requires 700 units in the beginning of week 3. Hence, they need to order for 700 units (as the lot size is lot-for-lot) two weeks before (as the lead-time is 2 weeks). Thus, company need to order the required units in week 1.

- Projected on hand inventory for week 4 is 0 units. Calculation is as follows:

b)

To prepare A Material requirement plan for the given information.

Introduction: Materials Requirement Planning (MRP) is the planning or scheduling system, which can be used in the manufacturing process. It is used to plan the number of items required to produce one unit of finished goods (end item).

Explanation of Solution

Given information:

On-hand balances are 100 units of Component N and 0 units of Component E. Scheduled receipts is 40 units of Component I and 10 units of Component C would arrive at the beginning of week 3. 100 units of Component E are needed at the beginning of week 5 and 55 units needed at the beginning of week 7. Lot size is multiple of 800 for Component N, multiples of 200 for Component V, and lot-for-lot for Component E and Component I.

Product structure tree:

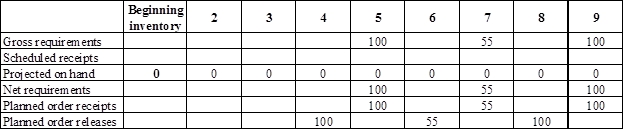

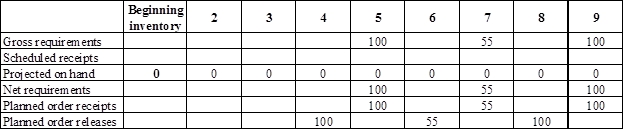

Develop a material requirement planning for End item E:

- It is given that Person X has received an order to deliver 100 units of End item E in the start of week 5 and 55 units of End item E in the start of week 7.

- Beginning inventory is given as 0 units.

- Net requirement can be calculated by subtracting the projected on-hand from the gross requirement. Hence, the net requirement is 100 units in week 5 (100-0).

- Planned order release is the order given by the company and planned order receipts is the order received by the firm.

- Lead-time is given as 1 week. Company requires 100 units in the beginning of Week 5. Hence, they need to order for 100 units (as the lot size is lot-for-lot) on previous week (as the lead-time is 1 week). Thus, company need to order the required units in week 4.

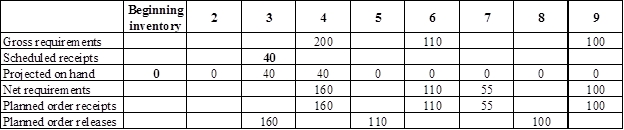

Develop a material requirement planning for Component I (2):

- End item E is the parent item of Component I (2). Hence, the planned order release of E is the gross requirement for Component I (2). As number of units required is 2 for Component I, the planned order release row should be multiplied with 2 to attain the gross requirement column of Component I.

- Beginning inventory is given as 0 units.

- Scheduled receipt is 40 units at the beginning of week 3.

- Net requirement can be calculated by subtracting the projected on-hand from the gross requirement. Hence, the net requirement is 160 units on week 4 (200-40).

- Planned order release is the order given by the company and planned order receipts is the order received by the firm.

- Lead-time is given as 1 week. Company requires 160 units in the beginning of week 4. Hence, they need to order for 160 units (as the lot size is lot-for-lot) on previous week (as the lead-time is 1 week). Thus, company need to order the required units in week 3.

- Projected on hand inventory for week 5 is 0 units. Calculation is as follows:

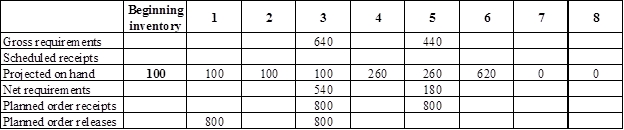

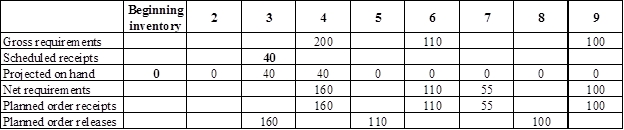

Develop a material requirement planning for Component N (4):

- Component I (2) is the parent item of Component N (4). Hence, the planned order release of Component I (2) is the gross requirement for Component N (4). As number of units required is 4 for Component N, the planned order release row should be multiplied with 2 to attain the gross requirement column of Component N.

- Beginning inventory is given as 100 units.

- Net requirement can be calculated by subtracting the projected on-hand from the gross requirement. Hence, the net requirement is 540 units on week 3 (640-100).

- Planned order release is the order given by the company and planned order receipts is the order received by the firm.

- Lead-time is given as 2 weeks. The company requires 540 units in the beginning of week 3. Hence, they need to order for 800 units (as the lot size is multiples of 800) two weeks before (as the lead-time is 2 weeks). Thus, company need to order the required units in week 1.

- Projected on hand inventory for week 4 is 260 units. Calculation is as follows:

- Projected on hand inventory for week 6 is 620 units. Calculation is as follows:

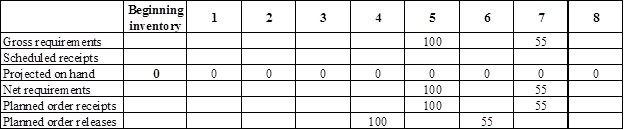

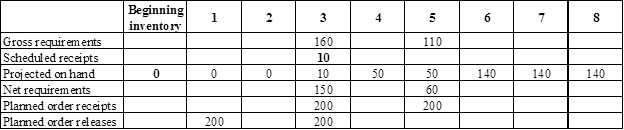

Develop a material requirement planning for Component V:

- Component I (2) is the parent item of Component V. Hence, the planned order release of Component I (2) is the gross requirement for Component V. As number of units required is 1 for Component V, the planned order release row should be multiplied with 1 to attain the gross requirement column of Component V.

- Beginning inventory is given as 0 units.

- Scheduled receipt is 10 units at the beginning of week 3.

- Net requirement can be calculated by subtracting the projected on-hand from the gross requirement. Hence, the net requirement is 150 units on week 3 (160-10).

- Planned order release is the order given by the company and planned order receipts is the order received by the firm.

- Lead-time is given as 2 weeks. The company requires 150 units in the beginning of week 3. Hence, they need to order for 200 units (as the lot size is multiples of 200) two weeks before (as the lead-time is 2 weeks). Thus, company need to order the required units in week 1.

- Projected on hand inventory for week 4 is 50 units. Calculation is as follows:

- Projected on hand inventory for week 6 is 140 units. Calculation is as follows:

c)

1)

To prepare: Material requirement plan for the given information.

Introduction: Materials Requirement Planning (MRP) is the planning or scheduling system, which can be used in the manufacturing process. It is used to plan the number of items required to produce one unit of finished goods (end item).

Explanation of Solution

Given information:

On-hand balances are 100 units of Component N and 0 units of Component E. Scheduled receipts is 800 units of Component N and 200 units of Component V would arrive at the beginning of week 3. Lot size is multiple of 800 for Component N, multiples of 200 for Component V, and lot-for-lot for Component E and Component I.

Week 1 has elapsed. Hence, plan has to be prepared from week 2 through week 9. 100 units of Component E are needed at the beginning of week 5 and 55 units needed at the beginning of week 7. In addition to that, 100 units of End item E are needed in week 9.

Product structure tree:

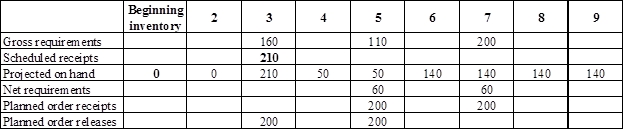

Develop a material requirement planning for End item E:

- It is given that Person X has received an order to deliver 100 units of End item E in week 5, 55 units in week 7, and 100 units in week 9.

- Beginning inventory is given as 0 units.

- Net requirement can be calculated by subtracting the projected on-hand from the gross requirement. Hence, the net requirement is 100 units (100-0).

- Planned order release is the order given by the company and planned order receipts is the order received by the firm.

- Lead-time is given as 1 week. Company requires 100 units in the beginning of week 5. Hence, they need to order for 100 units (as the lot size is lot-for-lot) on previous week (as the lead-time is 1 week). Thus, company need to order the required units in week 4.

Develop a material requirement planning for Component I (2):

- End item E is the parent item of Component I (2). Hence, the planned order release of E is the gross requirement for Component I (2). As number of units required is 2 for Component I, the planned order release row should be multiplied with 2 to attain the gross requirement column of Component I.

- Beginning inventory is given as 0 units.

- Scheduled receipt is 40 units at the beginning of week 3.

- Net requirement can be calculated by subtracting the projected on-hand from the gross requirement. Hence, the net requirement is 160 units on week 4 (200-40).

- Planned order release is the order given by the company and planned order receipts is the order received by the firm.

- Lead-time is given as 1 week. Company requires 160 units in the beginning of week 4. Hence, they need to order for 160 units (as the lot size is lot-for-lot) on previous week (as the lead-time is 1 week). Thus, company need to order the required units in week 3.

- Projected on hand inventory for week 5 is 0 units. Calculation is as follows:

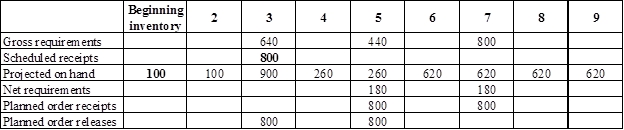

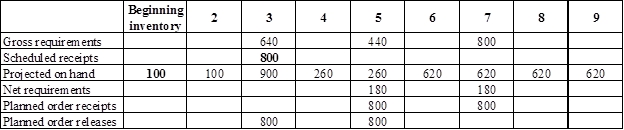

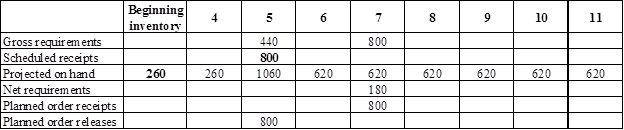

Develop a material requirement planning for Component N (4):

- Component I (2) is the parent item of Component N (4). Hence, the planned order release of Component I (2) is the gross requirement for Component N (4). As number of units required is 4 for Component N, the planned order release row should be multiplied with 2 to attain the gross requirement column of Component N.

- Beginning inventory is given as 100 units.

- Scheduled receipt is 800 units at the beginning of week 3

- Net requirement can be calculated by subtracting the projected on-hand from the gross requirement. Hence, the net requirement is 180 units on week 5 (440-260).

- Planned order release is the order given by the company and planned order receipts is the order received by the firm.

- Lead-time is given as 2 weeks. The company requires 180 units in the beginning of week 5. Hence, they need to order for 800 units (as the lot size is multiples of 800) two weeks before (as the lead-time is 2 weeks). Thus, company need to order the required units in week 3.

- Projected on hand inventory for week 4 is 260 units. Calculation is as follows:

- Projected on hand inventory for week 6 is 620 units. Calculation is as follows:

Develop a material requirement planning for Component V:

- Component I (2) is the parent item of Component V. Hence, the planned order release of Component I (2) is the gross requirement for Component V. As number of units required is 1 for Component V, the planned order release row should be multiplied with 1 to attain the gross requirement column of Component V.

- Beginning inventory is given as 0 units.

- Scheduled receipt is 210 units at the beginning of week 3.

- Net requirement can be calculated by subtracting the projected on-hand from the gross requirement. Hence, the net requirement is 60 units on week 5 (110-50).

- Planned order release is the order given by the company and planned order receipts is the order received by the firm.

- Lead-time is given as 2 weeks. The company requires 700 units in the beginning of week 3. Hence, they need to order for 700 units (as the lot size is lot-for-lot) two weeks before (as the lead-time is 2 weeks). Thus, company need to order the required units in week 1.

- Projected on hand inventory for week 4 is 50 units. Calculation is as follows:

- Projected on hand inventory for week 6 is 140 units. Calculation is as follows:

1)

To prepare: Material requirement plan for the given information.

Introduction: Materials Requirement Planning (MRP) is the planning or scheduling system, which can be used in the manufacturing process. It is used to plan the number of items required to produce one unit of finished goods (end item).

Explanation of Solution

Given information:

On-hand balances are 100 units of Component N and 0 units of Component E. Scheduled receipts is 800 units of Component N and 200 units of Component V would arrive at the beginning of week 3. Lot size is multiple of 800 for Component N, multiples of 200 for Component V, and lot-for-lot for Component E and Component I.

Week 1 has elapsed. Hence, plan has to be prepared from week 2 through week 9. 100 units of Component E are needed at the beginning of week 5 and 55 units needed at the beginning of week 7. In addition to that, 100 units of End item E are needed in week 9.

Product structure tree:

Develop a material requirement planning for End item E:

- It is given that Person X has received an order to deliver 100 units of End item E in week 5, 55 units in week 7, and 100 units in week 9.

- Beginning inventory is given as 0 units.

- Net requirement can be calculated by subtracting the projected on-hand from the gross requirement. Hence, the net requirement is 100 units (100-0).

- Planned order release is the order given by the company and planned order receipts is the order received by the firm.

- Lead-time is given as 1 week. Company requires 100 units in the beginning of week 5. Hence, they need to order for 100 units (as the lot size is lot-for-lot) on previous week (as the lead-time is 1 week). Thus, company need to order the required units in week 4.

Develop a material requirement planning for Component I (2):

- End item E is the parent item of Component I (2). Hence, the planned order release of E is the gross requirement for Component I (2). As number of units required is 2 for Component I, the planned order release row should be multiplied with 2 to attain the gross requirement column of Component I.

- Beginning inventory is given as 0 units.

- Scheduled receipt is 40 units at the beginning of week 3.

- Net requirement can be calculated by subtracting the projected on-hand from the gross requirement. Hence, the net requirement is 160 units on week 4 (200-40).

- Planned order release is the order given by the company and planned order receipts is the order received by the firm.

- Lead-time is given as 1 week. Company requires 160 units in the beginning of week 4. Hence, they need to order for 160 units (as the lot size is lot-for-lot) on previous week (as the lead-time is 1 week). Thus, company need to order the required units in week 3.

- Projected on hand inventory for week 5 is 0 units. Calculation is as follows:

Develop a material requirement planning for Component N (4):

- Component I (2) is the parent item of Component N (4). Hence, the planned order release of Component I (2) is the gross requirement for Component N (4). As number of units required is 4 for Component N, the planned order release row should be multiplied with 2 to attain the gross requirement column of Component N.

- Beginning inventory is given as 100 units.

- Scheduled receipt is 800 units at the beginning of week 3

- Net requirement can be calculated by subtracting the projected on-hand from the gross requirement. Hence, the net requirement is 180 units on week 5 (440-260).

- Planned order release is the order given by the company and planned order receipts is the order received by the firm.

- Lead-time is given as 2 weeks. The company requires 180 units in the beginning of week 5. Hence, they need to order for 800 units (as the lot size is multiples of 800) two weeks before (as the lead-time is 2 weeks). Thus, company need to order the required units in week 3.

- Projected on hand inventory for week 4 is 260 units. Calculation is as follows:

- Projected on hand inventory for week 6 is 620 units. Calculation is as follows:

Develop a material requirement planning for Component V:

- Component I (2) is the parent item of Component V. Hence, the planned order release of Component I (2) is the gross requirement for Component V. As number of units required is 1 for Component V, the planned order release row should be multiplied with 1 to attain the gross requirement column of Component V.

- Beginning inventory is given as 0 units.

- Scheduled receipt is 210 units at the beginning of week 3.

- Net requirement can be calculated by subtracting the projected on-hand from the gross requirement. Hence, the net requirement is 60 units on week 5 (110-50).

- Planned order release is the order given by the company and planned order receipts is the order received by the firm.

- Lead-time is given as 2 weeks. The company requires 700 units in the beginning of week 3. Hence, they need to order for 700 units (as the lot size is lot-for-lot) two weeks before (as the lead-time is 2 weeks). Thus, company need to order the required units in week 1.

- Projected on hand inventory for week 4 is 50 units. Calculation is as follows:

- Projected on hand inventory for week 6 is 140 units. Calculation is as follows:

2)

To prepare: Material requirement plan for the given information.

Introduction: Materials Requirement Planning (MRP) is the planning or scheduling system, which can be used in the manufacturing process. It is used to plan the number of items required to produce one unit of finished goods (end item).

Explanation of Solution

Given information:

On-hand balances are 100 units of Component N and 0 units of Component E. Lot size is multiple of 800 for Component N, multiples of 200 for Component V, and lot-for-lot for Component E and Component I.

Two weeks (week 2 and week 3) has elapsed. Hence, plan has to be prepared from week 4 through week 11. 100 units of Component E are needed at the beginning of week 5 and 55 units needed at the beginning of week 7. In addition to that, 100 units of End item E are needed in week 9.

Planned order releases from 2nd and 3rd week should be used as scheduled receipt units. Scheduled receipt are 160 units of Component I at the start of 4th week, 800 units of Component N at the start of 5th week, and 200 units of Component V at the start of 5th week.

Product structure tree:

Develop a material requirement planning for End item E:

- It is given that Person X has received an order to deliver 100 units of End item E in week 5, 55 units in week 7, and 100 units in week 9.

- Beginning inventory is given as 0 units.

- Net requirement can be calculated by subtracting the projected on-hand from the gross requirement. Hence, the net requirement is 100 units at week 5 (100-0).

- Planned order release is the order given by the company and planned order receipts is the order received by the firm.

- Lead-time is given as 1 week. Company requires 100 units in the beginning of week 5. Hence, they need to order for 100 units (as the lot size is lot-for-lot) on previous week (as the lead-time is 1 week). Thus, company need to order the required units in week 4.

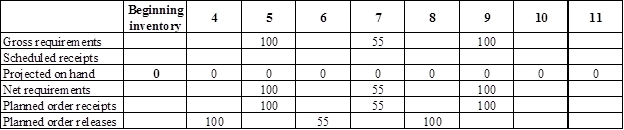

Develop a material requirement planning for Component I (2):

- End item E is the parent item of Component I (2). Hence, the planned order release of E is the gross requirement for Component I (2). As number of units required is 2 for Component I, the planned order release row should be multiplied with 2 to attain the gross requirement column of Component I.

- Beginning inventory is given as 40 units.

- Scheduled receipt is 160 units at the beginning of week 4.

- Net requirement can be calculated by subtracting the projected on-hand from the gross requirement. Hence, the net requirement is 100 units on week 6 (110-0).

- Planned order release is the order given by the company and planned order receipts is the order received by the firm.

- Lead-time is given as 1 week. Company requires 110 units in the beginning of week 6. Hence, they need to order for 110 units (as the lot size is lot-for-lot) on previous week (as the lead-time is 1 week). Thus, company need to order the required units in week 5.

- Projected on hand inventory for week 5 is 0 units. Calculation is as follows:

Develop a material requirement planning for Component N (4):

- Component I (2) is the parent item of Component N (4). Hence, the planned order release of Component I (2) is the gross requirement for Component N (4). As number of units required is 4 for Component N, the planned order release row should be multiplied with 2 to attain the gross requirement column of Component N.

- Beginning inventory is given as 260 units.

- Scheduled receipt is 800 units at the beginning of week 3

- Net requirement can be calculated by subtracting the projected on-hand from the gross requirement. Hence, the net requirement is 180 units on week 7 (800-620).

- Planned order release is the order given by the company and planned order receipts is the order received by the firm.

- Lead-time is given as 2 weeks. The company requires 180 units in the beginning of week 7. Hence, they need to order for 800 units (as the lot size is multiples of 800) two weeks before (as the lead-time is 2 weeks). Thus, company need to order the required units in week 5.

- Projected on hand inventory for week 5 is 1,060 units. Calculation is as follows:

- Projected on hand inventory for week 6 is 620 units. Calculation is as follows:

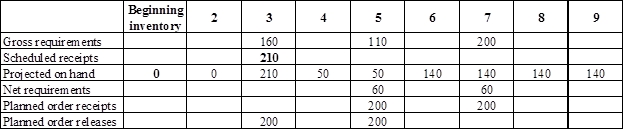

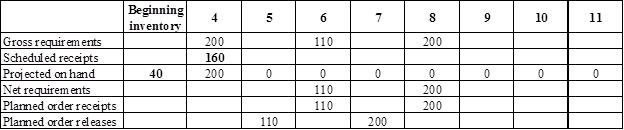

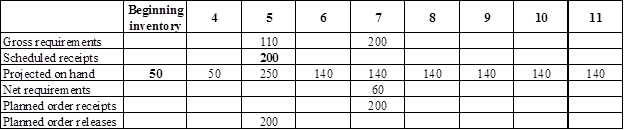

Develop a material requirement planning for Component V:

- Component I (2) is the parent item of Component V. Hence, the planned order release of Component I (2) is the gross requirement for Component V. As number of units required is 1 for Component V, the planned order release row should be multiplied with 1 to attain the gross requirement column of Component V.

- Beginning inventory is given as 50 units.

- Scheduled receipt is 200 units at the beginning of week 5.

- Net requirement can be calculated by subtracting the projected on-hand from the gross requirement. Hence, the net requirement is 60 units on week 7 (200-140).

- Planned order release is the order given by the company and planned order receipts is the order received by the firm.

- Lead-time is given as 2 weeks. The company requires 60 units in the beginning of week 7. Hence, they need to order for 200 units (as the lot size is multiples of 200) two weeks before (as the lead-time is 2 weeks). Thus, company need to order the required units in week 5.

- Projected on hand inventory for week 6 is 140 units. Calculation is as follows:

Want to see more full solutions like this?

Chapter 12 Solutions

Operations Management (McGraw-Hill Series in Operations and Decision Sciences)

Additional Business Textbook Solutions

Intermediate Accounting (2nd Edition)

Managerial Accounting (5th Edition)

Marketing: An Introduction (13th Edition)

Horngren's Accounting (12th Edition)

Essentials of MIS (13th Edition)

Horngren's Cost Accounting: A Managerial Emphasis (16th Edition)

- EXPLAIN Human Resource Information System (HRIS)arrow_forwardRead the mini-case study below and answer the following questions.With an enormous amount of data stored in databases and data warehouses, it is increasinglyimportant to develop powerful tools for analysis of such data and mining interestingknowledge from it. Data mining is a process of inferring knowledge from such huge data. Themain problem related to the retrieval of information from the World Wide Web is theenormous number of unstructured documents and resources, i.e., the difficulty of locating andtracking appropriate sources.Briefly explain any five (5) types of information you can get from data mining.arrow_forwardProblem 1: Practice Problems Chapter 6 Managing Quality The accounts receivable department has documented the following defects over a 30-day period: Category Frequency Invoice amount does not agree with the check amount 108 Invoice not on record (not found) 24 No formal invoice issued Check (payment) not received on time 18 30 Check not signed 8 Invoice number and invoice referenced do not agree 12 What techniques would you use and what conclusions can you draw about defects in the accounts receivable department? Problem 2: Prepare a flow chart for purchasing a Big Mac at the drive-through window at McDonalds. Problem 3: Draw a fishbone chart detailing reasons why a part might not be correctly machined.arrow_forward

- Problem 5: Development of a new deluxe version of a particular software product is being considered. The activities necessary for the completion of this project are listed in the table below along with their costs and completion times in weeks. Activity Normal Crash Normal Crash Immediate Time Time Cost Cost Predecessor A 4 3 2,000 2,600 B 2 1 2,200 2,800 A C 3 3 500 500 A D 8 4 2,300 2,600 A E 6 3 900 1,200 B, D F 3 2 3,000 4,200 C, E G 4 2 1,400 2,000 F a. What is the project expected completion date? b. What is the total cost required for completing this project on normal time? c. If you wish to reduce the time required to complete this project by 1 week, which activity should be crashed, and how much will this increase the total cost?arrow_forwardI need answer typing clear urjent no chatgpt used pls i will give 5 Upvotes.with diagramarrow_forwardnot use ai pleasearrow_forward

- provide scholarly reseach and references for the following 1. explain operational risks and examples of such risk faced by management at financial institutions 2. discuss the importance of establishing an effective risk management policy at financial institutions to manage operational risk, giving example of a risk management strategy used by financial institutions to mitigate such risk. 3. what is the rold of the core principles of effective bank supervision as it relates to operational risk, in the effective management of financial institutions.arrow_forwardPlease show all units, work, and steps needed to solve this problem I need answer typing clear urjent no chatgpt used pls i will give 5 Upvotes.arrow_forwardIM.82 A distributor of industrial equipment purchases specialized compressors for use in air conditioners. The regular price is $50, however, the manufacturer of this compressor offers quantity discounts per the following discount schedule: Option Plan Quantity Discount A 1 - 299 0% B 300 - 1,199 0.50% C 1,200+ 1.50% The distributor pays $56 each time it places an order with the manufacturer. Holding costs are negligible (none) but they do earn 10% annual interest on all cash balances (meaning there will be a financial opportunity cost when they put cash into inventory). Annual demand is expected to be 10,750 units. When there is no quantity discount (Option Plan A, the first row of the schedule listed above), what is the adjusted order quantity? (Display your answer to the nearest whole number.) 491 Based on your answer to the previous question, and based on the annual demand as stated above, what will be the annual ordering costs? (Display your answer to the…arrow_forward

- Excel Please. The workload of many areas of banking operations varies considerably based on time of day. A variable capacity can be achieved effectively by employing part-time personnel. Because part-timers are not entitled to all the fringe benefits, they are often more economical than full-time employees. Other considerations, however, may limit the extent to which part-time people can be hired in a given department. The problem is to find an optimal workforce schedule that would meet personnel requirements at any given time and also be economical. Some of the factors affecting personnel assignments are listed here: The bank is open from 9:00am to 7:00pm. Full-time employees work for 8 hours (1 hour for lunch included) per day. They do not necessarily have to start their shift when the bank opens. Part-time employees work for at least 4 hours per day, but less than 8 hours per day and do not get a lunch break. By corporate policy, total part-time personnel hours is limited…arrow_forwardIM.84 An outdoor equipment manufacturer sells a rugged water bottle to complement its product line. They sell this item to a variety of sporting goods stores and other retailers. The manufacturer offers quantity discounts per the following discount schedule: Option Plan Quantity Price A 1 - 2,399 $5.50 B 2,400 - 3,999 $5.20 C 4,000+ $4.50 A large big-box retailer expects to sell 9,700 units this year. This retailer estimates that it incurs an internal administrative cost of $225 each time it places an order with the manufacturer. Holding cost for the retailer is $55 per case per year. (There are 40 units or water bottles per case.) Based on this information, and not taking into account any quantity discount offers, what is the calculated EOQ (in units)? (Display your answer to the nearest whole number.) Number Based on this information, sort each quantity discount plan from left to right by dragging the MOST preferred option plan to the left, and the LEAST preferred…arrow_forwardIn less than 150 words, what is an example of what your reflection of core values means to you and your work: Commitment, Perseverance, Community, Service, Pride?arrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,MarketingMarketingISBN:9780357033791Author:Pride, William MPublisher:South Western Educational Publishing

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,MarketingMarketingISBN:9780357033791Author:Pride, William MPublisher:South Western Educational Publishing Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning