Concept explainers

To determine: The number of suppliers to be chosen by Company W.

Introduction:

Answer to Problem 3P

TheCompany W can choose one supplier.

Explanation of Solution

Given information:

Formula:

Calculation for supplier selection:

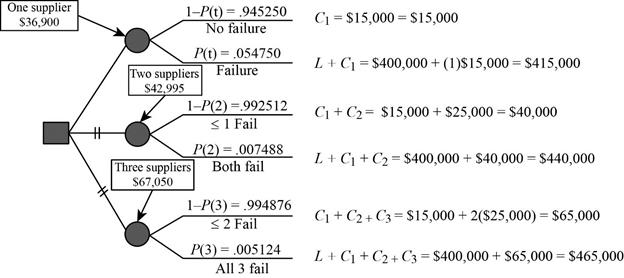

Probability of selecting one supplier:

To find the probability of selecting one supplier, substitute the number of chosen suppliers, probability of super-event and unique-event in the above formula. Here, the number of suppliers chosen is ‘1’; S=0.005 and U=0.05 are substituted in the above formula, which gives the probability as 0.05475.

Probability of selecting two suppliers:

To find the probability of selecting two suppliers, substitute the number of chosen suppliers, probability of super-event and unique-event in the above formula. Here, the number of suppliers chosen is ‘2’; S=0.005 and U=0.05 are substituted in the above formula, which gives the probability as 0.007488.

Probability of selecting three suppliers:

To find the probability of selecting three suppliers, substitute the number of chosen suppliers, probability of super-event and unique-event in the above formula. Here, the number of suppliers chosen is ‘3’; S=0.005 and U=0.05 are substituted in the above formula, which gives the probability as 0.00512.

Calculation of cost:

Failure cost and no-failure cost is calculated for every number of suppliers selected.

- When one supplier is selected:

- Calculation of no-failure cost:

When there is no failure of supplier, then there is no loss, when one supplier is selected. The only cost associated with the supplier selection is the marginal cost.

Probability of no-failure for one supplier,

- Calculation of failure cost:

When the supplier selection fails, along with marginal cost, the supplier failure cost is also added to the failure cost.

- Calculation of total cost:

The total cost is calculated by summing up the values obtained by multiplying the cost with respective probabilities.

The total cost of selecting one supplier is $36,900.

- When two suppliers are selected:

- Calculation of no-failure cost:

When there is no failure of suppliers, then there is no loss, when two suppliers are selected. The only cost associated with the supplier selection is the marginal cost.

Probability of no-failure for two suppliers,

- Calculation of failure cost:

When the supplier selection fails, along with marginal cost, the supplier failure cost is also added to the failure cost.

- Calculation of total cost:

The total cost is calculated by summing up the values obtained by multiplying the cost with respective probabilities.

The total cost of selecting two suppliers is $42,995.

- When three suppliers are selected:

- Calculation of no-failure cost:

When there is no failure of suppliers, then there is no loss, when three suppliers are selected. The only cost associated with the supplier selection is the marginal cost.

Probability of no-failure for three suppliers,

- Calculation of failure cost:

When the supplier selection fails, along with marginal cost, the supplier failure cost is also added to the failure cost.

- Calculation of total cost:

The total cost is calculated by summing up the values obtained by multiplying the cost with respective probabilities.

The total cost of selecting three suppliers is $67,050.

From Equations ((1), (2) and (3)), it can be inferred that the total cost is low, when one supplier is selected. Therefore, it is advisable for Company W to select one supplier.

Hence, Company W can choose one supplier.

Want to see more full solutions like this?

Chapter 11 Solutions

EBK PRINCIPLES OF OPERATIONS MANAGEMENT

- How does rework hurt a process? Give examples on how rework can hurt a process. Please provide a referencearrow_forwardHow does rework hurt a process? Give examples on how rework can hurt a process. Please provide a referencearrow_forwardWhat the different between a near miss and hazard 1. movement and contact 2. Contact 3. movementarrow_forward

- The fixed and variable costs for three potential manufacturing plant sites for a rattan chair weaver are shown: Site Fixed Cost Per Year Variable Cost per Unit 1 $700 $12.00 2 $1,000 $7.00 $2,200 $5.00 a) After rounding to the nearest whole number, site 1 is best below After rounding to the nearest whole number, site 2 is best between After rounding to the nearest whole number, site 3 is best above b) If the demand is 590 units, then the best location for the potent 3 units. and units. 600 0 60 units. g plant isarrow_forwardRefer to Table S6.1 - Factors for Computing Control Chart Limits (3 sigma) for this problem. Sampling 4 pieces of precision-cut wire (to be used in computer assembly) every hour for the past 24 hours has produced the following results: Hour R Hour X R Hour X R Hour X R 1 3.25" 0.71" 7 3.15" 0.58" 13 3.11" 0.85" 19 4.51" 1.56" 2 3.20 1.18 8 2.65 1.08 14 2.83 1.31 20 2.79 1.14 3 3.12 1.38 9 15 4. 3.39 1.31 10 5 2.97 1.17 6 2.76 0.32 3.02 0.71 3.12 1.01 2.75 1.33 16 2.74 0.50 22 11 2.73 1.17 17 2.76 1.43 23 12 2.87 0.45 18 2.64 1.24 21 2.75 1.03 3.18 0.46 2.94 1.53 24 2.54 0.97 Based on the sampling done, the control limits for 3-sigma x chart are (round all intermediate calculations to three decimal places before proceeding with further calculations): Upper Control Limit (UCL) = inches (round your response to three decimal places). Lower Control Limit (LCL) = inches (round your response to three decimal places). Based on the x-chart, the wire cutting process has been The control limits…arrow_forwardChoose a specific cars company. E.g Toyota, Volkswagen, Hyundai, Mercedes-Benz, BMW, Honda, Ford, Audi, Tesla Define a list of required machinery, equipment, workstations, offices, rest areas, materials, etc. Develop and define the location of machinery, equipment, workstations, offices, rest areas, materials. Make the distribution in the manufacturing facility the most efficient way possible. Develop a process distribution for one specific product. Explain why you consider this is the most efficient distribution for this specific manufacturing facility. demonstrate the benefits of optimizing a production line with the best distribution of its equipment and spaces. To be more productive and profitable.arrow_forward

- Provide a Synposis of the Articlearrow_forwardThe goal of understanding personality in negotiation is to better predict behavior, such as the counterparty's acceptance or rejection of a negotiation offer. One investigation used acoustic and visual cues to predict the likely behavior of a counterparty to a proposal. The best visual cue predictor of the counterparty (55%) was whether they _____. A. tilted their head B. had their arms and legs crossed C. steepled their fingers D. tapped a penarrow_forwardWomen who ask for what they want in negotiation are less well-liked than women who do not self-advocate. However, nonassertive, other-advocating women suffer a leadership backlash and are regarded as less competent because their behavior is regarded to be _____ and _____. A. high-negative feminine; low-positive masculine B. high-positive feminine; high-positive masculine C. high-negative masculine; low-negative feminine D. low-positive masculine; low-positive femininearrow_forward

- There are five most recognized personality traits that can reliably be measured and predict negotiator behavior in a number of different situations. All of the following are one of those "Big 5" personality traits except _____. A. conscientiousness B. introversion C. agreeableness D. openness to experiencearrow_forwardWith regard to reputation in negotiation, negotiators who use adversarial, stubborn, and ethically questionable behavior often have the effect of _____. A. improving their business relationships B. decreasing their effectiveness as a negotiator C. improving their business relationships D. decreasing their group statusarrow_forwardWhen it comes to assertiveness, there is only a modest link between negotiators' self-views and how the counterparty sees them. Many negotiators come away from a negotiation thinking they came on too strong with the counterparty. The _____ refers to the fact that negotiators believe they are coming on too strong with the counterparty, but they actually are not. A. Collective trap illusion B. Attribution error C. Aggressive anchoring bias D. Line-crossing illusionarrow_forward

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Contemporary MarketingMarketingISBN:9780357033777Author:Louis E. Boone, David L. KurtzPublisher:Cengage Learning

Contemporary MarketingMarketingISBN:9780357033777Author:Louis E. Boone, David L. KurtzPublisher:Cengage Learning