Concept explainers

SummerFun. Inc., produces a variety of recreation and leisure products. The

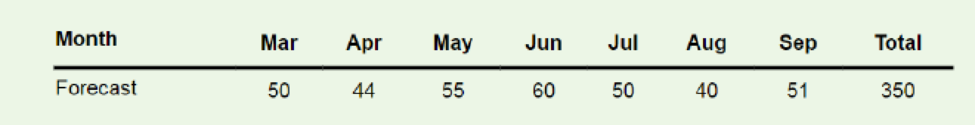

Use the following information to develop aggregate plans.

Develop an aggregate plan using each of the following guidelines and compute the total cost for each plan. Hint: You will need extra output in April and August to accommodate demand in the following months.

a. Use regular production. Supplement using inventory, overtime, and subcontracting as needed. No backlogs allowed.

b. Use a level strategy. Use a combination of backlogs, subcontracting, and inventory to handle variations in demand. There should not be a backlog in the final period.

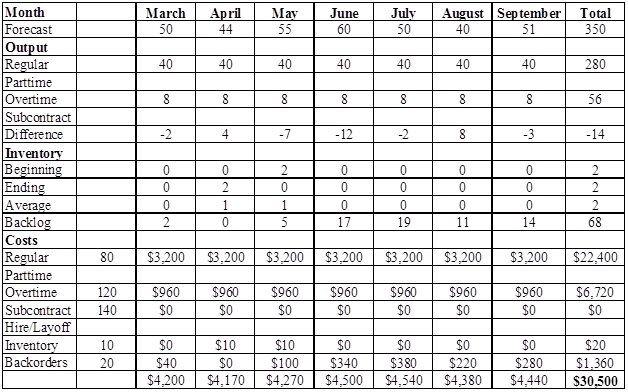

a)

To determine: The total cost using an aggregate plan.

Introduction:The aggregate plan is the output of sales and operations planning. The major concern of aggregate planning is the production time and quantity for the intermediate future. Aggregate planning would encompass a time prospect of approximately 3 to 18 months.

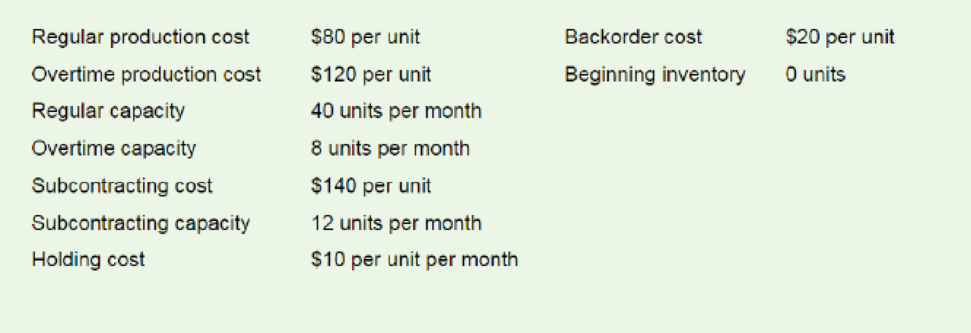

Answer to Problem 7P

Explanation of Solution

Given information:

Regular production cost is $80, overtime production cost is $120, subcontracting cost is $140, backorder cost is $20, holding cost is $10, regular capacity is 40 units, overtime cost is 8 units, and subcontracting capacity is 12 units. Beginning inventory is given as 0 units. In addition to this forecast for 7 months is given as follows:

| Month | March | April | May | June | July | August | September | Total |

| Forecast | 50 | 44 | 55 | 60 | 50 | 40 | 51 | 350 |

Determine the total cost of the plan:

It is given that regular productions should be used. No backlogs are allowed. Supplements can be satisfied using overtime, subcontracting, and inventory.

Supporting explanation:

Forecast and regular time capacity are given. Regular time capacity is given as 40 units, remaining units should be produced using the overtime capacity. Maximum overtime capacity is given as 8 units. Thus, if the forecast is not satisfied, it can be produced using the subcontract:

Calculate the difference for the month of March:

It is the calculation of difference between forecast and output. Hence, it can be calculated by subtracting the forecast from the output. Hence, the difference is 0 units.

Calculate the difference for the month of April:

It is the calculation of difference between forecast and output. Hence, it can be calculated by subtracting the forecast from the output. Hence, the difference is 4 units.

Calculate the difference for the month of May:

It is the calculation of difference between forecast and output. Hence, it can be calculated by subtracting the forecast from the output. Hence, the difference is -4 units.

Note: The calculation repeats for all the months.

Beginning inventory:

The initial inventory is given as 0. For the remaining months, ending inventory of previous month would be the beginning inventory of present month.

Ending inventory for the month of March:

Ending inventory can be determined by adding the beginning inventory and difference between output and forecast. Hence, the ending inventory is 0 units.

Ending inventory for the month of April:

Ending inventory can be determined by adding the beginning inventory and difference between output and forecast. Hence, the ending inventory is 4 units.

Ending inventory for the month of May:

Ending inventory can be determined by adding the beginning inventory and difference between output and forecast. Hence, the ending inventory is 0 units.

Note: The calculation repeats for all the months.

Average inventory for the month of March:

It is calculated by taking an average of beginning inventory and ending inventory. Hence, the average inventory is 0 units.

Average inventory for the month of April:

It is calculated by taking an average of beginning inventory and ending inventory. Hence, the average inventory is 2 units.

Average inventory for the month of May:

It is calculated by taking an average of beginning inventory and ending inventory. Hence, the average inventory is 2 units.

Note: The calculation repeats for all the months.

Calculate the regular time cost for the month of March:

Regular time cost per unit is given as $80 and regular time unit is given as 40. Regular time cost is calculated by multiplying regular time unit and regular time cost per unit. Hence, the regular time cost is $3,200.

Calculate the regular time cost for the month of April:

Regular time cost per unit is given as $80 and regular time unit is given as 40. Regular time cost is calculated by multiplying regular time unit and regular time cost per unit. Hence, the regular time cost is $3,200.

Calculate the regular time cost for the month of May:

Regular time cost per unit is given as $80 and regular time unit is given as 40. Regular time cost is calculated by multiplying regular time unit and regular time cost per unit. Hence, the regular time cost is $3,200.

Note: The calculation repeats for all the months.

Calculate the total regular time cost:

It is calculated by adding the regular time cost of all the months.

Hence, the total regular time cost is $22,400.

Calculate the overtime cost for the month of March:

Overtime cost per unit is given as $120 and overtime unit is given as 8. Overtime cost is calculated by multiplying overtime unit and overtime cost per unit. Hence, the overtime cost is $960.

Calculate the overtime cost for the month of April:

Overtime cost per unit is given as $120 and overtime unit is given as 8. Overtime cost is calculated by multiplying overtime unit and overtime cost per unit. Hence, the overtime cost is $960.

Calculate the overtime cost for the month of May:

Overtime cost per unit is given as $120 and overtime unit is given as 8. Overtime cost is calculated by multiplying overtime unit and overtime cost per unit. Hence, the overtime cost is $960.

Note: The calculation repeats for all the months.

Calculate the total overtime cost:

It is calculated by adding the overtime cost of all the months.

Hence, the total overtime cost is 6,120.

Calculate the subcontract cost for the month of March:

Subcontract cost per unit is given as $140 and subcontract unit is given as 2. Subcontract cost is calculated by multiplying subcontract unit and subcontract cost per unit. Hence, the subcontract cost is $280.

Calculate the subcontract cost for the month of April:

Subcontract cost per unit is given as $140 and subcontract unit is given as 0. Subcontract cost is calculated by multiplying subcontract unit and subcontract cost per unit. Hence, the subcontract cost is $0.

Calculate the subcontract cost for the month of May:

Subcontract cost per unit is given as $140 and subcontract unit is given as 3. Subcontract cost is calculated by multiplying subcontract unit and subcontract cost per unit. Hence, the subcontract cost is $420.

Note: The calculation repeats for all the months.

Calculate the total subcontract cost:

It is calculated by adding the subcontract cost of all the months.

Hence, the total subcontract cost is $2,660.

Calculate the inventory cost for the month of March:

It is calculated by average balance inventory cost and the average inventory units. Hence, the inventory cost is $0.

Calculate the inventory cost for the month of April:

It is calculated by average balance inventory cost and the average inventory units. Hence, the inventory cost is $20.

Calculate the inventory cost for the month of May:

It is calculated by average balance inventory cost and the average inventory units. Hence, the inventory cost is $20.

Note: The calculation repeats for all the months.

Calculate the total inventory cost:

It is calculated by adding the inventory cost of all the months.

Hence, the total inventory cost is $70.

Calculate the backorder cost for the month of March:

It is calculated by multiplying the backorder cost and the backlog. Hence, the backorder cost is $0.

Calculate the backorder cost for the month of April:

It is calculated by multiplying the backorder cost and the backlog. Hence, the backorder cost is $0.

Calculate the backorder cost for the month of May:

It is calculated by multiplying the backorder cost and the backlog. Hence, the backorder cost is $0.

Note: The calculation repeats for all the months.

Calculate the total cost of the plan:

It is calculated by adding the total regular time cost, overtime cost, subcontract cost, and inventory cost.

Hence, the total cost of the plan is $31,250.

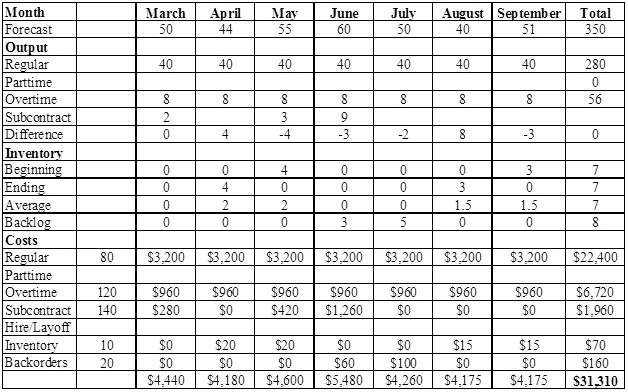

b)

To determine: The total cost using a level strategy of aggregate planning.

Introduction:Level production strategy is a production strategy used to produce at a constant rate. This strategy keeps constant level of workforce and backlog of demand.

Answer to Problem 7P

Explanation of Solution

Given information:

Regular production cost is $80, overtime production cost is $120, subcontracting cost is $140, backorder cost is $20, holding cost is $10, regular capacity is 40 units, overtime cost is 8 units, and subcontracting capacity is 12 units. Beginning inventory is given as 0 units. In addition to this forecast for 7 months is given as follows:

| Month | March | April | May | June | July | August | September | Total |

| Forecast | 50 | 44 | 55 | 60 | 50 | 40 | 51 | 350 |

Determine the total cost of the plan:

Subcontracting, inventory, and backlogs can be used to handle the fluctuations in the demand. Initial solution using regular time and overtime without using subcontracting is as follows:

Supporting explanation:

Determine the regular time productivity:

It is calculated by taking an average of the given forecast.

Calculate the difference for the month of March:

It is the calculation of difference between forecast and output. Hence, it can be calculated by subtracting the forecast from the output. Hence, the difference is -2 units.

Calculate the difference for the month of April:

It is the calculation of difference between forecast and output. Hence, it can be calculated by subtracting the forecast from the output. Hence, the difference is 4 units.

Calculate the difference for the month of May:

It is the calculation of difference between forecast and output. Hence, it can be calculated by subtracting the forecast from the output. Hence, the difference is --7 units.

Note: The calculation repeats for all the months.

Beginning inventory:

The initial inventory is given as 0. For the remaining months, ending inventory of previous month would be the beginning inventory of present month.

Ending inventory for the month of March:

Ending inventory can be determined by adding the beginning inventory and difference between output and forecast. Hence, the ending inventory is 0 units.

Ending inventory for the month of April:

Ending inventory can be determined by adding the beginning inventory and difference between output and forecast. Difference between output and forecast is 2 (4-2). Hence, the ending inventory is 2 units.

Ending inventory for the month of May:

Ending inventory can be determined by adding the beginning inventory and difference between output and forecast. Hence, the ending inventory is 0 units.

Note: The calculation repeats for all the months.

Average inventory for the month of March:

It is calculated by taking an average of beginning inventory and ending inventory. Hence, the average inventory is 0 units.

Average inventory for the month of April:

It is calculated by taking an average of beginning inventory and ending inventory. Hence, the average inventory is 1unit.

Average inventory for the month of May:

It is calculated by taking an average of beginning inventory and ending inventory. Hence, the average inventory is 1unit.

Note: The calculation repeats for all the months.

Backlogs for the month of 1:

It is number of units required in the month. As there is no previous month for 1st month, the difference would be the backlog. Hence, the backlog for 1st is 2 units.

Backlogs for the month of 2:

As the difference is positive, there would not be backlog.

Backlogs for the month of 3:

It is number of units required in the month. It is calculated by adding the backlog of previous month and the difference between output and forecast of current month (without considering the negative sign). Hence, the backlog is 5 units.

Note: The calculation repeats for all the months.

Calculate the regular time cost for the month of March:

Regular time cost per unit is given as $80 and regular time unit is given as 40. Regular time cost is calculated by multiplying regular time unit and regular time cost per unit. Hence, the regular time cost is $3,200.

Calculate the regular time cost for the month of April:

Regular time cost per unit is given as $80 and regular time unit is given as 40. Regular time cost is calculated by multiplying regular time unit and regular time cost per unit. Hence, the regular time cost is $3,200.

Calculate the regular time cost for the month of May:

Regular time cost per unit is given as $80 and regular time unit is given as 40. Regular time cost is calculated by multiplying regular time unit and regular time cost per unit. Hence, the regular time cost is $3,200.

Note: The calculation repeats for all the months.

Calculate the total regular time cost:

It is calculated by adding the regular time cost of all the months.

Hence, the total regular time cost is $22,400.

Calculate the overtime cost for the month of March:

Overtime cost per unit is given as $120 and overtime unit is given as 8. Overtime cost is calculated by multiplying overtime unit and overtime cost per unit. Hence, the overtime cost is $960.

Calculate the overtime cost for the month of April:

Overtime cost per unit is given as $120 and overtime unit is given as 8. Overtime cost is calculated by multiplying overtime unit and overtime cost per unit. Hence, the overtime cost is $960.

Calculate the overtime cost for the month of May:

Overtime cost per unit is given as $120 and overtime unit is given as 8. Overtime cost is calculated by multiplying overtime unit and overtime cost per unit. Hence, the overtime cost is $960.

Note: The calculation repeats for all the months.

Calculate the total overtime cost:

It is calculated by adding the overtime cost of all the months.

Hence, the total overtime cost is 6,120.

Calculate the subcontract cost for the month of March:

Subcontract cost per unit is given as $140 and subcontract unit is given as 0. Subcontract cost is calculated by multiplying subcontract unit and subcontract cost per unit. Hence, the subcontract cost is $140.

Calculate the subcontract cost for the month of April:

Subcontract cost per unit is given as $140 and subcontract unit is given as 0. Subcontract cost is calculated by multiplying subcontract unit and subcontract cost per unit. Hence, the subcontract cost is $0.

Calculate the subcontract cost for the month of May:

Subcontract cost per unit is given as $140 and subcontract unit is given as 0. Subcontract cost is calculated by multiplying subcontract unit and subcontract cost per unit. Hence, the subcontract cost is $0.

Note: The calculation repeats for all the months.

Calculate the total subcontract cost:

It is calculated by adding the subcontract cost of all the months.

Hence, the total subcontract cost is $0.

Calculate the inventory cost for the month of March:

It is calculated by average balance inventory cost and the average inventory units. Hence, the inventory cost is $0.

Calculate the inventory cost for the month of April:

It is calculated by average balance inventory cost and the average inventory units. Hence, the inventory cost is $10.

Calculate the inventory cost for the month of May:

It is calculated by average balance inventory cost and the average inventory units. Hence, the inventory cost is $10.

Note: The calculation repeats for all the months.

Calculate the total inventory cost:

It is calculated by adding the inventory cost of all the months.

Hence, the total inventory cost is $70.

Calculate the backorder cost for the month of March:

It is calculated by multiplying the backorder cost and the backlog. Hence, the backorder cost is $40.

Calculate the backorder cost for the month of April:

It is calculated by multiplying the backorder cost and the backlog. Hence, the backorder cost is $0.

Calculate the backorder cost for the month of May:

It is calculated by multiplying the backorder cost and the backlog. Hence, the backorder cost is $100.

Note: The calculation repeats for all the months.

Calculate the total backorder cost:

It is calculated by adding the backorder cost of all the months.

Hence, the total backorder cost is $1,360.

Calculate the total cost of the plan:

It is calculated by adding the total regular time cost, overtime cost, subcontract cost, and inventory cost.

Hence, the total cost of the plan is $30,500.

Determine the total cost of the plan:

Subcontracting, inventory, and backlogs can be used to handle the fluctuations in the demand. Final solution using regular time, overtime, and subcontracting is as follows:

Supporting explanation:

Determine the regular time productivity:

It is calculated by taking an average of the given forecast.

Calculate the difference for the month of March:

It is the calculation of difference between forecast and output. Hence, it can be calculated by subtracting the forecast from the output. Hence, the difference is 0 units.

Calculate the difference for the month of April:

It is the calculation of difference between forecast and output. Hence, it can be calculated by subtracting the forecast from the output. Hence, the difference is 4 units.

Calculate the difference for the month of May:

It is the calculation of difference between forecast and output. Hence, it can be calculated by subtracting the forecast from the output. Hence, the difference is -4 units.

Note: The calculation repeats for all the months.

Beginning inventory:

The initial inventory is given as 0. For the remaining months, ending inventory of previous month would be the beginning inventory of present month.

Ending inventory for the month of March:

Ending inventory can be determined by adding the beginning inventory and difference between output and forecast. Hence, the ending inventory is 0 units.

Ending inventory for the month of April:

Ending inventory can be determined by adding the beginning inventory and difference between output and forecast. Hence, the ending inventory is 4 units.

Ending inventory for the month of May:

Ending inventory can be determined by adding the beginning inventory and difference between output and forecast. Hence, the ending inventory is 0 units.

Note: The calculation repeats for all the months.

Average inventory for the month of March:

It is calculated by taking an average of beginning inventory and ending inventory. Hence, the average inventory is 0 units.

Average inventory for the month of April:

It is calculated by taking an average of beginning inventory and ending inventory. Hence, the average inventory is 2 units.

Average inventory for the month of May:

It is calculated by taking an average of beginning inventory and ending inventory. Hence, the average inventory is 2 units.

Note: The calculation repeats for all the months.

Backlogs for the month of June:

It is number of units required in the month. It is calculated by adding the backlog of previous month and the difference between output and forecast of current month (without considering the negative sign). Hence, the backlog is 3 units.

Backlogs for the month of July:

It is number of units required in the month. It is calculated by adding the backlog of previous month and the difference between output and forecast of current month (without considering the negative sign). Hence, the backlog is 5 units.

Note: The calculation repeats for all the months.

Calculate the regular time cost for the month of March:

Regular time cost per unit is given as $80 and regular time unit is given as 40. Regular time cost is calculated by multiplying regular time unit and regular time cost per unit. Hence, the regular time cost is $3,200.

Calculate the regular time cost for the month of April:

Regular time cost per unit is given as $80 and regular time unit is given as 40. Regular time cost is calculated by multiplying regular time unit and regular time cost per unit. Hence, the regular time cost is $3,200.

Calculate the regular time cost for the month of May:

Regular time cost per unit is given as $80 and regular time unit is given as 40. Regular time cost is calculated by multiplying regular time unit and regular time cost per unit. Hence, the regular time cost is $3,200.

Note: The calculation repeats for all the months.

Calculate the total regular time cost:

It is calculated by adding the regular time cost of all the months.

Hence, the total regular time cost is $22,400.

Calculate the overtime cost for the month of March:

Overtime cost per unit is given as $120 and overtime unit is given as 8. Overtime cost is calculated by multiplying overtime unit and overtime cost per unit. Hence, the overtime cost is $960.

Calculate the overtime cost for the month of April:

Overtime cost per unit is given as $120 and overtime unit is given as 8. Overtime cost is calculated by multiplying overtime unit and overtime cost per unit. Hence, the overtime cost is $960.

Calculate the overtime cost for the month of May:

Overtime cost per unit is given as $120 and overtime unit is given as 8. Overtime cost is calculated by multiplying overtime unit and overtime cost per unit. Hence, the overtime cost is $960.

Note: The calculation repeats for all the months.

Calculate the total overtime cost:

It is calculated by adding the overtime cost of all the months.

Hence, the total overtime cost is 6,120.

Calculate the subcontract cost for the month of March:

Subcontract cost per unit is given as $140 and subcontract unit is given as 2. Subcontract cost is calculated by multiplying subcontract unit and subcontract cost per unit. Hence, the subcontract cost is $280.

Calculate the subcontract cost for the month of April:

Subcontract cost per unit is given as $140 and subcontract unit is given as 0. Subcontract cost is calculated by multiplying subcontract unit and subcontract cost per unit. Hence, the subcontract cost is $0.

Calculate the subcontract cost for the month of May:

Subcontract cost per unit is given as $140 and subcontract unit is given as 3. Subcontract cost is calculated by multiplying subcontract unit and subcontract cost per unit. Hence, the subcontract cost is $420.

Note: The calculation repeats for all the months.

Calculate the total subcontract cost:

It is calculated by adding the subcontract cost of all the months.

Hence, the total subcontract cost is $1,960.

Calculate the inventory cost for the month of March:

It is calculated by average balance inventory cost and the average inventory units. Hence, the inventory cost is $0.

Calculate the inventory cost for the month of April:

It is calculated by average balance inventory cost and the average inventory units. Hence, the inventory cost is $20.

Calculate the inventory cost for the month of May:

It is calculated by average balance inventory cost and the average inventory units. Hence, the inventory cost is $20.

Note: The calculation repeats for all the months.

Calculate the total inventory cost:

It is calculated by adding the inventory cost of all the months.

Hence, the total inventory cost is $70.

Calculate the backorder cost for the month of March:

It is calculated by multiplying the backorder cost and the backlog. Hence, the backorder cost is $0.

Calculate the backorder cost for the month of April:

It is calculated by multiplying the backorder cost and the backlog. Hence, the backorder cost is $0.

Calculate the backorder cost for the month of May:

It is calculated by multiplying the backorder cost and the backlog. Hence, the backorder cost is $0.

Note: The calculation repeats for all the months.

Calculate the total backorder cost:

It is calculated by adding the backorder cost of all the months.

Hence, the total backorder cost is $160.

Calculate the total cost of the plan:

It is calculated by adding the total regular time cost, overtime cost, subcontract cost, and inventory cost.

Hence, the total cost of the plan is $31,310.

Want to see more full solutions like this?

Chapter 11 Solutions

Loose-leaf for Operations Management (The Mcgraw-hill Series in Operations and Decision Sciences)

- [-16.66 Points] DETAILS MY NOTES CAMMIMS16 4.E.008. 0/1 Submissions Used A linear programming computer package is needed. ASK YOUR TEACHER PRACTICE ANOTHER The Clark County Sheriff's Department schedules police officers for 8-hour shifts. The beginning times for the shifts are 8:00 a.m., noon, 4:00 p.m., 8:00 p.m., midnight, and 4:00 a.m. An officer beginning a shift at one of these times works for the next 8 hours. During normal weekday operations, the number of officers needed varies depending on the time of day. The department staffing guidelines require the following minimum number of officers on duty: Time of Day 8:00 A.M. Noon Noon - 4:00 P.M. Minimum Officers Time of Day on Duty 4 7 4:00 P.M. - 8:00 P.M. 11 8:00 P.M. Midnight 6 Midnight 4:00 A.M. 4:00 A.M. -8:00 A.M. 3 7 Determine the number of police officers that should be scheduled to begin the 8-hour shifts at each of the six times (8:00 a.m., noon, 4:00 p.m., 8:00 p.m., midnight, and 4:00 a.m.) to minimize the total number…arrow_forwarddiscuss in detail the benefits of working in a teamarrow_forwardExplain why some people resist working in a team.arrow_forward

- Discuss the Open Systems Approach to Teamworkarrow_forwarddiscuss team development stagesarrow_forwardLearning Activity 6: Canadian Business This Year Read the following webpage: The Business Development Bank of Canada. (2023). Canadian economic outlook for 2024: Shifting into neutral. https://www.bdc.ca/en/articles- tools/blog/canadian-economic-outlook-for-2024- shifting-into-neutral "Despite persistently high inflation and rising. interest rates, the news was generally better than expected for the Canadian economy in 2023" (BDC Blog 2024). Discussion Question: In your view, what are the most pressing problems for Canadian companies or consumers in 2024? Explain your answer using current examples of companies or consumer concerns.arrow_forward

- Travelling and working internationally can lead to a life of adventure and unique career experiences. For businesses, selecting the right candidates to take on foreign assignments can propel, delay, or deny the success of the international ventures. As an international manager, identify key competencies you would look for in choosing expatriates. What might be some of their concerns in taking on overseas assignments? What are some best practices in supporting expats during and after their assignments?arrow_forwardResearch proposal: The Investigation of Career Development and Job satisfaction atEskom Rotek Industries 1. Introduction (250 words) 2. Research Context: Background (Research Context: Background (250 words) 3. The Research Problem (The Research Problem) 4. Aim of the study (Maximum 50 words) 5. Research Objectives (3 in total) 6. Research Questions (3 in total) 7. Justification or rationale of the study (150 words) 8. Literature Review (2-3 pages / 1000-1500 words) 9. Research Design and Methodology (1 - 2 page in total, from 9.1 to 9.6) 9.1 Research Philosophy 9.2 Research Methodology 9.3 Target Population and Sampling strategy 9.4 Data Collection 9.5 Data Analysis (100 words) 9.6 Pilot Study 10. Ethical considerations 11. Referencearrow_forwardWith your experience and research, discuss;(a) what type of “Leadership Style” is used in communications services (Digicel Group Limited)?(b) whether the style used is successful or not and why. Justify your position with relevant citation and references ( Rubic is attached to guide the essay ) NOTE: NO AI RESPONSES PLEASEarrow_forward

- by the end of 2013, the IPL port was operational and the naphtha was flowing to the Himachal Fertilizer Corporation (HFC) plant in Central India after being granted the port contract in Summer 2012. The plant was located in an industrial area that had several pipelines in the general geographic area including a crude oil pipeline leading to a refinery, and a pipeline carrying pesticides to be processed and redistributed to local farms in the area. In July 2014, Ajay Patel, the logistics general manager received notification that there were some minor leaks along the pipeline that were being fixed. Workers in the area had experienced sudden headaches and lightheadedness and the company immediately moved to investigate the leak and address faulty seams that had eroded and weakened. The flow of naphtha was temporarily stopped for 72 hours so two portions of the pipeline could be removed, and the eroded portions replaced. Patel put enormous pressure on the repair team to get the repair…arrow_forwardin the MABE: learning to be multinational case report, what is the reccomended course of action?arrow_forwardIn the MABE case report what would be the reccomened course of action?arrow_forward

- MarketingMarketingISBN:9780357033791Author:Pride, William MPublisher:South Western Educational Publishing

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,  Foundations of Business (MindTap Course List)MarketingISBN:9781337386920Author:William M. Pride, Robert J. Hughes, Jack R. KapoorPublisher:Cengage Learning

Foundations of Business (MindTap Course List)MarketingISBN:9781337386920Author:William M. Pride, Robert J. Hughes, Jack R. KapoorPublisher:Cengage Learning