EBK OPERATIONS MANAGEMENT

12th Edition

ISBN: 8220100283963

Author: Stevenson

Publisher: YUZU

expand_more

expand_more

format_list_bulleted

Concept explainers

Textbook Question

Chapter 11, Problem 23P

Prepare a

Note: The ATP quantities are based on maximum allowable production.

Note: A negative projected on-hand can occur.

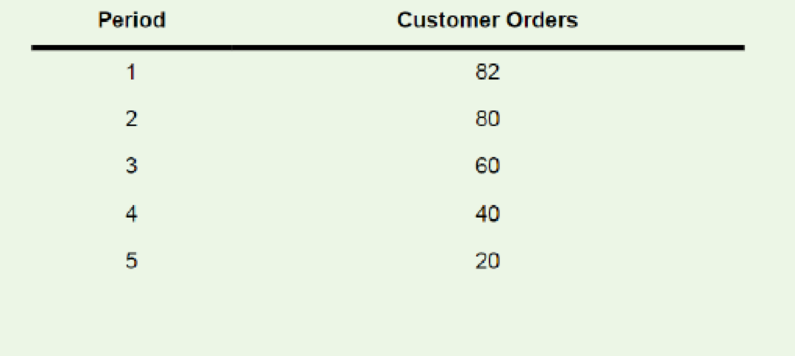

Committed orders are as follows.

Expert Solution & Answer

Want to see the full answer?

Check out a sample textbook solution

Students have asked these similar questions

The Shades Sunglass Company assembles sunglasses from frames, which it makes,and lenses, which it purchases from an outside supplier. The sales department hasprepared the following 6-week forecast for Ebony, a popular model. The sunglassesare assembled in lots of 220, and the opening inventory is 300 pairs. Complete theprojected available balance and the master production schedule.

A company wants to develop a level production plan for a family of products. The opening inventory is 550 units, and a decrease to 200 units is expected by the end of the plan.The demand for each of the periods is given in what follows. All periods have the samenumber of working days. How much should the company produce each period? Whatwill be the ending inventories in each period? Do you see any problems with the plan?

Please solve this with proper explanation:

Chapter 11 Solutions

EBK OPERATIONS MANAGEMENT

Ch. 11 - What three levels of planning involve operations...Ch. 11 - What are the three phases of intermediate...Ch. 11 - Prob. 3DRQCh. 11 - Why is there a need for aggregate planning?Ch. 11 - What are the most common decision variables for...Ch. 11 - Prob. 6DRQCh. 11 - Briefly discuss the advantages and disadvantages...Ch. 11 - What are the primary advantages and limitations of...Ch. 11 - Briefly describe the planning techniques listed as...Ch. 11 - What are the inputs to master scheduling? What are...

Ch. 11 - Prob. 11DRQCh. 11 - What general trade-offs are involved in master...Ch. 11 - Who needs to interface with the master schedule...Ch. 11 - How has technology had an impact on master...Ch. 11 - Service operations often face more difficulty in...Ch. 11 - Name several behaviors related to aggregate...Ch. 11 - Compute the total cost for each aggregate plan...Ch. 11 - A manager would like to know the total cost of a...Ch. 11 - Determine the total cost for this plan given the...Ch. 11 - a. Given the following forecast and steady regular...Ch. 11 - Manager T. C. Downs of Plum Engines, a producer of...Ch. 11 - Manager Chris Channing of Fabric Mills, Inc., has...Ch. 11 - SummerFun. Inc., produces a variety of recreation...Ch. 11 - Nowjuice, Inc., produces Shakewell fruit juice. A...Ch. 11 - Wormwood, Ltd., produces a variety of furniture...Ch. 11 - Refer to Solved Problem 1. Prepare two additional...Ch. 11 - Refer to Solved Problem 1. Suppose another option...Ch. 11 - Prob. 12PCh. 11 - Prob. 13PCh. 11 - Prob. 14PCh. 11 - Prob. 15PCh. 11 - Refer to Example 3. Suppose that regular-time...Ch. 11 - Prob. 17PCh. 11 - Prob. 18PCh. 11 - Prepare a master production schedule for...Ch. 11 - Update the master schedule shown in Figure 11.11...Ch. 11 - Prepare a master schedule like that shown in...Ch. 11 - Determine the available-to-promise (ATP)...Ch. 11 - Prepare a schedule like that shown in Figure 11.12...Ch. 11 - The objective is to choose the plan that has the...Ch. 11 - Prob. 2CQ

Knowledge Booster

Learn more about

Need a deep-dive on the concept behind this application? Look no further. Learn more about this topic, operations-management and related others by exploring similar questions and additional content below.Similar questions

- Scenario 3 Ben Gibson, the purchasing manager at Coastal Products, was reviewing purchasing expenditures for packaging materials with Jeff Joyner. Ben was particularly disturbed about the amount spent on corrugated boxes purchased from Southeastern Corrugated. Ben said, I dont like the salesman from that company. He comes around here acting like he owns the place. He loves to tell us about his fancy car, house, and vacations. It seems to me he must be making too much money off of us! Jeff responded that he heard Southeastern Corrugated was going to ask for a price increase to cover the rising costs of raw material paper stock. Jeff further stated that Southeastern would probably ask for more than what was justified simply from rising paper stock costs. After the meeting, Ben decided he had heard enough. After all, he prided himself on being a results-oriented manager. There was no way he was going to allow that salesman to keep taking advantage of Coastal Products. Ben called Jeff and told him it was time to rebid the corrugated contract before Southeastern came in with a price increase request. Who did Jeff know that might be interested in the business? Jeff replied he had several companies in mind to include in the bidding process. These companies would surely come in at a lower price, partly because they used lower-grade boxes that would probably work well enough in Coastal Products process. Jeff also explained that these suppliers were not serious contenders for the business. Their purpose was to create competition with the bids. Ben told Jeff to make sure that Southeastern was well aware that these new suppliers were bidding on the contract. He also said to make sure the suppliers knew that price was going to be the determining factor in this quote, because he considered corrugated boxes to be a standard industry item. Is Ben Gibson acting legally? Is he acting ethically? Why or why not?arrow_forwardScenario 3 Ben Gibson, the purchasing manager at Coastal Products, was reviewing purchasing expenditures for packaging materials with Jeff Joyner. Ben was particularly disturbed about the amount spent on corrugated boxes purchased from Southeastern Corrugated. Ben said, I dont like the salesman from that company. He comes around here acting like he owns the place. He loves to tell us about his fancy car, house, and vacations. It seems to me he must be making too much money off of us! Jeff responded that he heard Southeastern Corrugated was going to ask for a price increase to cover the rising costs of raw material paper stock. Jeff further stated that Southeastern would probably ask for more than what was justified simply from rising paper stock costs. After the meeting, Ben decided he had heard enough. After all, he prided himself on being a results-oriented manager. There was no way he was going to allow that salesman to keep taking advantage of Coastal Products. Ben called Jeff and told him it was time to rebid the corrugated contract before Southeastern came in with a price increase request. Who did Jeff know that might be interested in the business? Jeff replied he had several companies in mind to include in the bidding process. These companies would surely come in at a lower price, partly because they used lower-grade boxes that would probably work well enough in Coastal Products process. Jeff also explained that these suppliers were not serious contenders for the business. Their purpose was to create competition with the bids. Ben told Jeff to make sure that Southeastern was well aware that these new suppliers were bidding on the contract. He also said to make sure the suppliers knew that price was going to be the determining factor in this quote, because he considered corrugated boxes to be a standard industry item. As the Marketing Manager for Southeastern Corrugated, what would you do upon receiving the request for quotation from Coastal Products?arrow_forwardThe table above provides the aggregate plan of production by a firm. It is known that the firm uses a level plan with lost sales, i.e., without backorders. Given this information, what is the number in the cell that says xx?arrow_forward

- Wine Accessories Inc. (WAI) produces two models of corkscrews, the standard model and a deluxe model. WAI follows a level aggregate plan, producing 20,000 corkscrews per month, or 5000 corkscrews per week. Th e MPS is developed in weekly time periods. Th e forecasts for each model and the projected available are shown in the next two tables. Th e replenishment order quantity is 2000 units for the standard model and 1000 units for the deluxe model. Note that you can place multipleorders if a single order is insuffi cient to cover the forecast (you can produce 4000 units of the standard model if necessary, or 2000 or 3000 units of the deluxe model). Remember that total weekly production is limited to 5000 corkscrews. Develop an MPS for each of the products.arrow_forwardPlease do not give solution in image format thankuarrow_forwardGiven the forecast and booked orders shown in the table, and a beginning inventory of 25, what should the master production schedule quantity be for period 4? Note:- Do not provide handwritten solution. Maintain accuracy and quality in your answer. Take care of plagiarism. Answer completely. You will get up vote for sure.arrow_forward

- Suppose we are formulating a Master Production Schedule (MPS) for an item. The lot-size policy for this item calls for a fixed quantity of 300 units. Lead time for this item is three weeks. Week O inventory for this item is 400 units. There are no safety stock requirements. Here are the demand forecast and the booked orders for this item.... Week 1 2 3 4 5 6 Forecast 120 120 100 100 100 120 Booked 115 121 71 0 0 0 When the master schedule is complete. what will be the Projected On-Hand in Week 4?arrow_forwardEXAMPLE: PRODUCTION PLAN STRATEGIES 1. Prepare the production plan using the three basic production plan strategies Suppose the forecasted demand for a product family looks like the table below. Assume the product family is a make to stock family with a starting inventory of 210. Period 1 2 3 4 5 6 Total Forecast 175 150 180 165 150 200 1020 (Demand) Additional Information: For Hybrid production, it is assumed that for the 1* three periods it uses the lowest demand; on the 4th and 5th period it uses 175 forecasted demand; and on the 6th period there is no change on the demand. Requirement: Solve for the following a. Chase production plan Period 1 2 3 4 5 6 Total Forecast (Demand) 175 150 180 165 150 200 1020 Level production plan Period 1 2 3 4 5 6 Total Forecast (Demand) 175 150 180 165 150 200 1020 b. Hybrid production plan Period 1 4 5 6. Total Forecast (Demand) 175 150 180 165 150 200 1020arrow_forwardMr. Zulhakim being assigned by his manager to develop their production planning for Year 2022. Table 3 shows the information that he able to obtain from the sales & marketing department. After doing the planning, Mr Zulhakim need to present it to his manager. Factory developed a demand forecast based on Table 3 with supplier charges about RM300.00 per unit. The demand forecast is stated as week but, in this planning, it is being considered as an annual quantity for the operation. Ordering cost is RM150.00. Annual holding cost is 10 percent of a purchased price. (b) Develop the ATP of this plan. Initial inventory on hand is 50 units obtained from Year 2021. Lot size for MPS can be obtained by using EOQ model. Table 3: Demand and Customer confirmed order quantity 8 9 10 2 3 10 40 10 00 30 20 40 20 30 Period (Week) 1 4 5 6 7 Forecast (units) Customer orders (booked) (unit) 20 8. 2arrow_forward

- Demand for stereo headphones and music players for joggers has caused Nina Industries to grow almost 50 percent over the past year. The number of joggers continues to expand, so Nina expects demand for headsets to also expand, because, as yet, no safety laws have been passed to prevent joggers from wearing them. Demand for the players for this year was as follows: MONTH DEMAND (UNITS) January 4,150 February 4,250 March 3,950 April 4,350 May 4,950 June 4,650 July 5,250 August 4,850 September 5,350 October 5,650 November 6,250 December 5,950 a. Using linear regression analysis, what would you estimate demand to be for each month next year? Using a spreadsheet, follow the general format in Exhibit 3.8. (Do not round intermediate calculations. Round your answers to 2 decimal places.) b. To be reasonably confident of meeting demand, Nina decides to use 3 standard errors of estimate for safety. How many additional units should be held to meet this…arrow_forwardWeek 1 3. 4 Forecast 45 45 45 45 Customer Order 42 45 42 50 Given the following data, calculate the projected available balance. The demand time fence is the end of week 3, the order quantity is 100, and 40 are available at the beginning of the periodarrow_forward3. The MPS planner at Murphy Motors uses MPS time-phased records for planning end-item pro- duction. The planner is currently working on a schedule for the P24, one of Murphy's top-selling motors. The planner uses a production lot size of 70 and a safety stock of 5 for the P24 motor. Item: P24 Forecast Orders On hand Week 12345678 30 30 30 40 40 40 45 45 13 8 4 Projected available balance Available-to-promise MPS 20 a. Complete the MPS time-phased record for product P24. b. Can Murphy accept the following orders? Update the MPS time-phased record for accepted orders. Order 1234 4 Amount 40 30 30 25 Desired Week 4 6 2 3arrow_forward

arrow_back_ios

SEE MORE QUESTIONS

arrow_forward_ios

Recommended textbooks for you

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage, Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Purchasing and Supply Chain ManagementOperations ManagementISBN:9781285869681Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. PattersonPublisher:Cengage Learning

Practical Management Science

Operations Management

ISBN:9781337406659

Author:WINSTON, Wayne L.

Publisher:Cengage,

Purchasing and Supply Chain Management

Operations Management

ISBN:9781285869681

Author:Robert M. Monczka, Robert B. Handfield, Larry C. Giunipero, James L. Patterson

Publisher:Cengage Learning

Inventory Management | Concepts, Examples and Solved Problems; Author: Dr. Bharatendra Rai;https://www.youtube.com/watch?v=2n9NLZTIlz8;License: Standard YouTube License, CC-BY