The liquid phase reaction 3R + Q→ 2P will be carried out isothermal Reactants R and Q and dilutent S will be fed at 60 ft³/min with the fol

The liquid phase reaction 3R + Q→ 2P will be carried out isothermal Reactants R and Q and dilutent S will be fed at 60 ft³/min with the fol

Introduction to Chemical Engineering Thermodynamics

8th Edition

ISBN:9781259696527

Author:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Chapter1: Introduction

Section: Chapter Questions

Problem 1.1P

Related questions

Question

100%

plz help w/ part a i will repost for other parts

![### CSTR Reactor Design for Liquid Phase Reaction

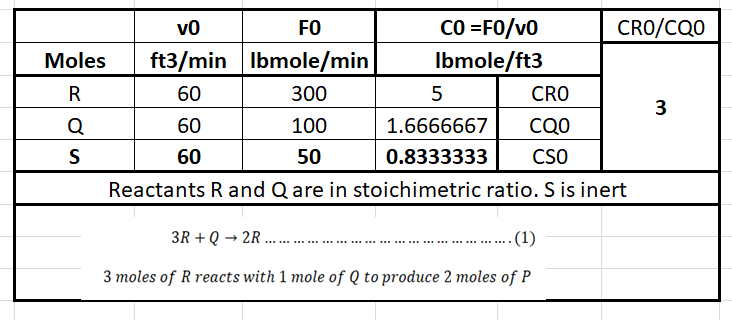

The liquid phase reaction \(3R + Q \rightarrow 2P\) will be carried out isothermally in a Continuous Stirred-Tank Reactor (CSTR). The reactants R and Q, along with diluent S, will be fed at a rate of 60 ft³/min, with the following molar flow rates:

- **Species R**: 300 lbmole/min

- **Species Q**: 100 lbmole/min

- **Species S**: 50 lbmole/min

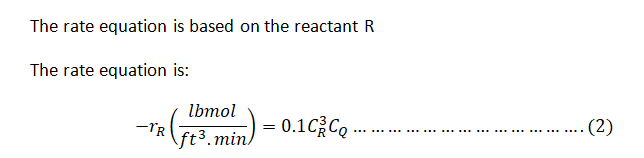

The rate law for the reaction is given by:

\[

-r_R \left( \frac{\text{lbmole}}{\text{ft}^3 \cdot \text{min}} \right) = 0.1 \times c_R^3 \times c_Q

\]

where \(c_R\) and \(c_Q\) are the concentrations of R and Q in lbmole/ft³.

### Reactor Design Specifications

The reactor is designed to achieve an 80% conversion of the limiting reactant. A consulting firm has proposed a pre-fabricated CSTR reactor with a volume of 500 cubic feet, claiming it will achieve at least 80% conversion for the given reaction.

### Tasks for Reactor Design

**A) Express the reaction rate equation in terms of conversion of the limiting reactant.**

**B) Develop the design equation for the reactor as a function of the initial concentration of the limiting reactant and its conversion.**

**C) Determine the volume of the CSTR reactor based on the given conversion and the final concentrations of all species involved in the system.**

**D) Is the design from the firm acceptable? Explain why or why not.**

These tasks will guide the evaluation of the reactor design to ensure that it meets the conversion requirements and operates efficiently.](/v2/_next/image?url=https%3A%2F%2Fcontent.bartleby.com%2Fqna-images%2Fquestion%2Fd47fc2c3-8f4b-4085-b234-bc909be774e3%2Fa1471dd6-4692-46e4-91d4-23d333b71fe6%2Fwxcra_processed.png&w=3840&q=75)

Transcribed Image Text:### CSTR Reactor Design for Liquid Phase Reaction

The liquid phase reaction \(3R + Q \rightarrow 2P\) will be carried out isothermally in a Continuous Stirred-Tank Reactor (CSTR). The reactants R and Q, along with diluent S, will be fed at a rate of 60 ft³/min, with the following molar flow rates:

- **Species R**: 300 lbmole/min

- **Species Q**: 100 lbmole/min

- **Species S**: 50 lbmole/min

The rate law for the reaction is given by:

\[

-r_R \left( \frac{\text{lbmole}}{\text{ft}^3 \cdot \text{min}} \right) = 0.1 \times c_R^3 \times c_Q

\]

where \(c_R\) and \(c_Q\) are the concentrations of R and Q in lbmole/ft³.

### Reactor Design Specifications

The reactor is designed to achieve an 80% conversion of the limiting reactant. A consulting firm has proposed a pre-fabricated CSTR reactor with a volume of 500 cubic feet, claiming it will achieve at least 80% conversion for the given reaction.

### Tasks for Reactor Design

**A) Express the reaction rate equation in terms of conversion of the limiting reactant.**

**B) Develop the design equation for the reactor as a function of the initial concentration of the limiting reactant and its conversion.**

**C) Determine the volume of the CSTR reactor based on the given conversion and the final concentrations of all species involved in the system.**

**D) Is the design from the firm acceptable? Explain why or why not.**

These tasks will guide the evaluation of the reactor design to ensure that it meets the conversion requirements and operates efficiently.

Expert Solution

Step 1: The Limiting reactant

Step by step

Solved in 4 steps with 6 images

Recommended textbooks for you

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Introduction to Chemical Engineering Thermodynami…

Chemical Engineering

ISBN:

9781259696527

Author:

J.M. Smith Termodinamica en ingenieria quimica, Hendrick C Van Ness, Michael Abbott, Mark Swihart

Publisher:

McGraw-Hill Education

Elementary Principles of Chemical Processes, Bind…

Chemical Engineering

ISBN:

9781118431221

Author:

Richard M. Felder, Ronald W. Rousseau, Lisa G. Bullard

Publisher:

WILEY

Elements of Chemical Reaction Engineering (5th Ed…

Chemical Engineering

ISBN:

9780133887518

Author:

H. Scott Fogler

Publisher:

Prentice Hall

Industrial Plastics: Theory and Applications

Chemical Engineering

ISBN:

9781285061238

Author:

Lokensgard, Erik

Publisher:

Delmar Cengage Learning

Unit Operations of Chemical Engineering

Chemical Engineering

ISBN:

9780072848236

Author:

Warren McCabe, Julian C. Smith, Peter Harriott

Publisher:

McGraw-Hill Companies, The